8 XL-FW232-02

REBUILDING PROCEDURES continued

Adjust the Fifth Wheel Locks:

1. Using a ratchet with 1/2˝ Allen wrench, tighten the

adjustment screw (

20) in the throat in the fifth wheel,

by turning the screw clockwise until tight.

2. Check that the kingpin on the lock tester is square to

the swinging lock (

6) and that the stationary lock is

square to the kingpin. If not square, align the kingpin

and/or stationary lock as necessary and retighten the

adjusting screw.

3. Tighten the lock nut (

19) on the stationary lock.

4. Loosen the adjustment screw (

20) by turning counter-

clockwise 1

1

⁄2 turns. The locking mechanism is now

properly adjusted.

Check that the secondary lock operates freely.

Check the operation of the fifth wheel by locking and

unlocking it several times.

CHECKING THE OPERATION OF THE FIFTH WHEEL

With the fifth wheel turned upright, it will

function as follows:

When the swinging lock (6) is open, the release handle

(

16) will be in; the plunger (17) will extend into the throat

area so that the step in the plunger is visible in the throat,

as shown in

FIGURE 18, and the secondary lock release

handle (

18) will be out, with the handle lug disengaged

from the top plate casting.

Fifth Wheel Coupling:

As the lock tester is coupled to the fifth wheel, the swinging

lock closes, pushing the plunger (

17) back, and the release

handle (

16) out.

As the swinging lock closes, the secondary lock spring will

move the secondary lock into the closed position behind

the swinging lock, and move the release handle inward.

When properly locked, the locking plunger (

17) will be

visible as shown in

FIGURE 18.

Fifth Wheel Uncoupling:

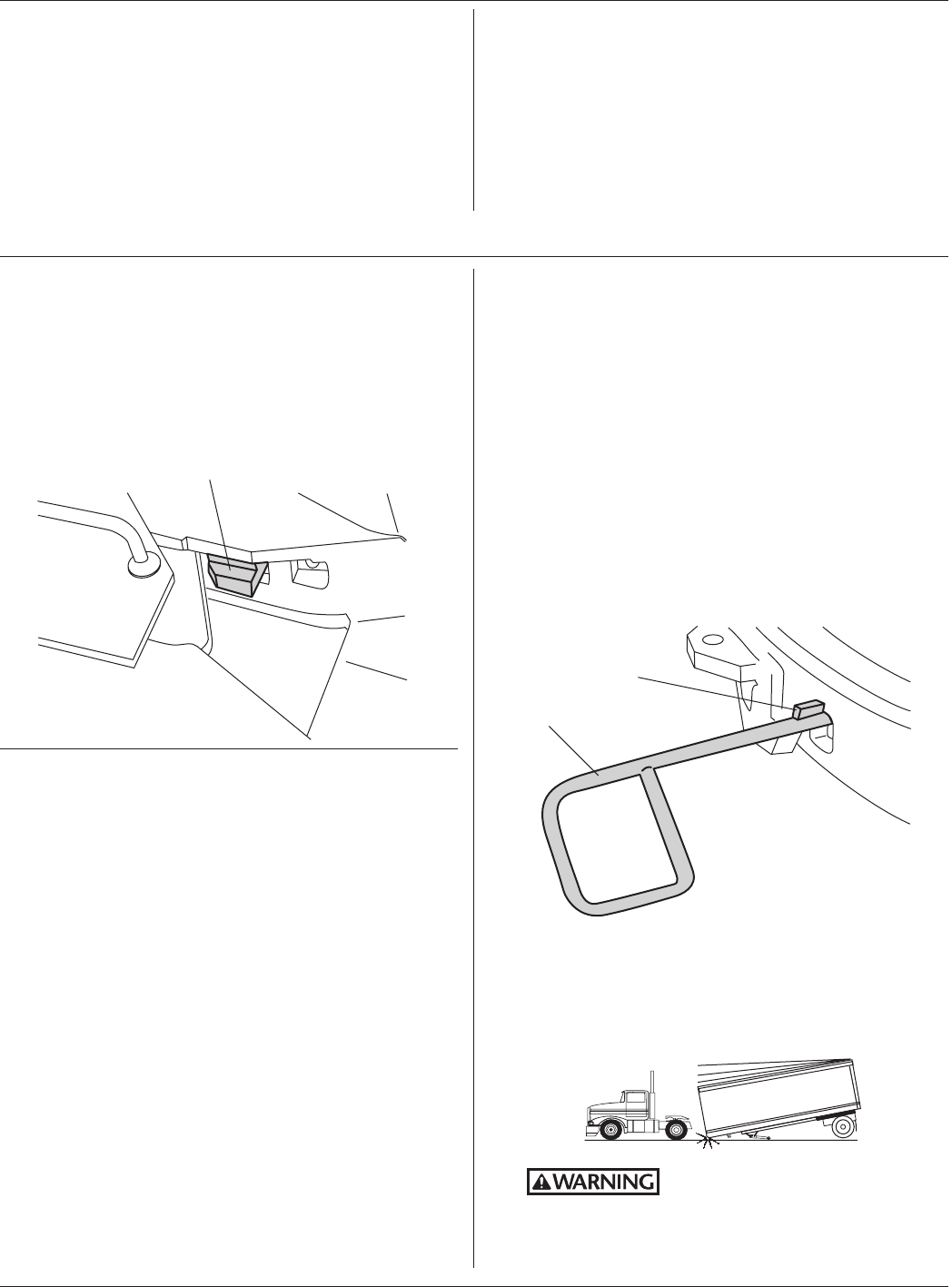

1. To uncouple the lock tester, pull the secondary lock

release handle (

9) out, raise it up and engage the

handle lug with the top plate casting (

FIGURE 19).

2. Then, pull the release handle (16) out, raise it up, and

engage its handle lug with the top plate casting

(

FIGURE 15 on page 7). This will retract the plunger

(

17) and hold it in so that the step in the plunger is

not visible in the throat area.

Step in the plunger (17)

FIGURE 18

3. As the kingpin on the lock tester is pulled out

(rearward), the swinging lock (

6) will open.

When the swinging lock opens, it will push the

plunger back slightly, causing the release handle (

16)

to extend outward slightly. This action disengages the

release handle from its notch in the casting, allowing

the release handle to move to the locked position.

As the swinging lock opens past the plunger, the

plunger will extend into the throat area and become

visible again. The release handle will move inward.

As the swinging lock opens fully, it will contact the

retracted secondary lock (

10), pushing the secondary

lock release handle slightly outward, causing its

handle lug to disengage and allowing the handle

to drop slightly.

4.

IMPORTANT: If the top plate assembly does not

operate properly,

DO NOT USE IT. Review the

“Troubleshooting Hints” on page 2 and rebuilding

procedures throughout this manual, or contact your

local HOLLAND representative for assistance.

Failure to properly install, operate,

or maintain this fifth wheel could

result in tractor and trailer separation causing death

or serious injury to others.

9

Secondary lock

release handle lug

FIGURE 19

➠