Dodge Engineering & Controls, Inc.

Toll Free (877) 334-2875 Fax: (978) 244-1422

Installation

EN221 and EN310 Non-Spring Return Electronic Actuators

Factory setting:

Switch A 5°

Switch B 85°

To change the settings of A and B:

• Make sure the actuator is in the 0 position. The

scale is valid only in the 0 position.

• Use a flat-blade screwdriver to turn the switch

adjustment dials to the desired setting at which a

signal is to be given.

80

70

60

50

B

90

AUX

SWITCH

ADJ

20

30

40

10

20

40

A

70

EA0304R1

Figure 16. Dual Auxiliary Switch Dials.

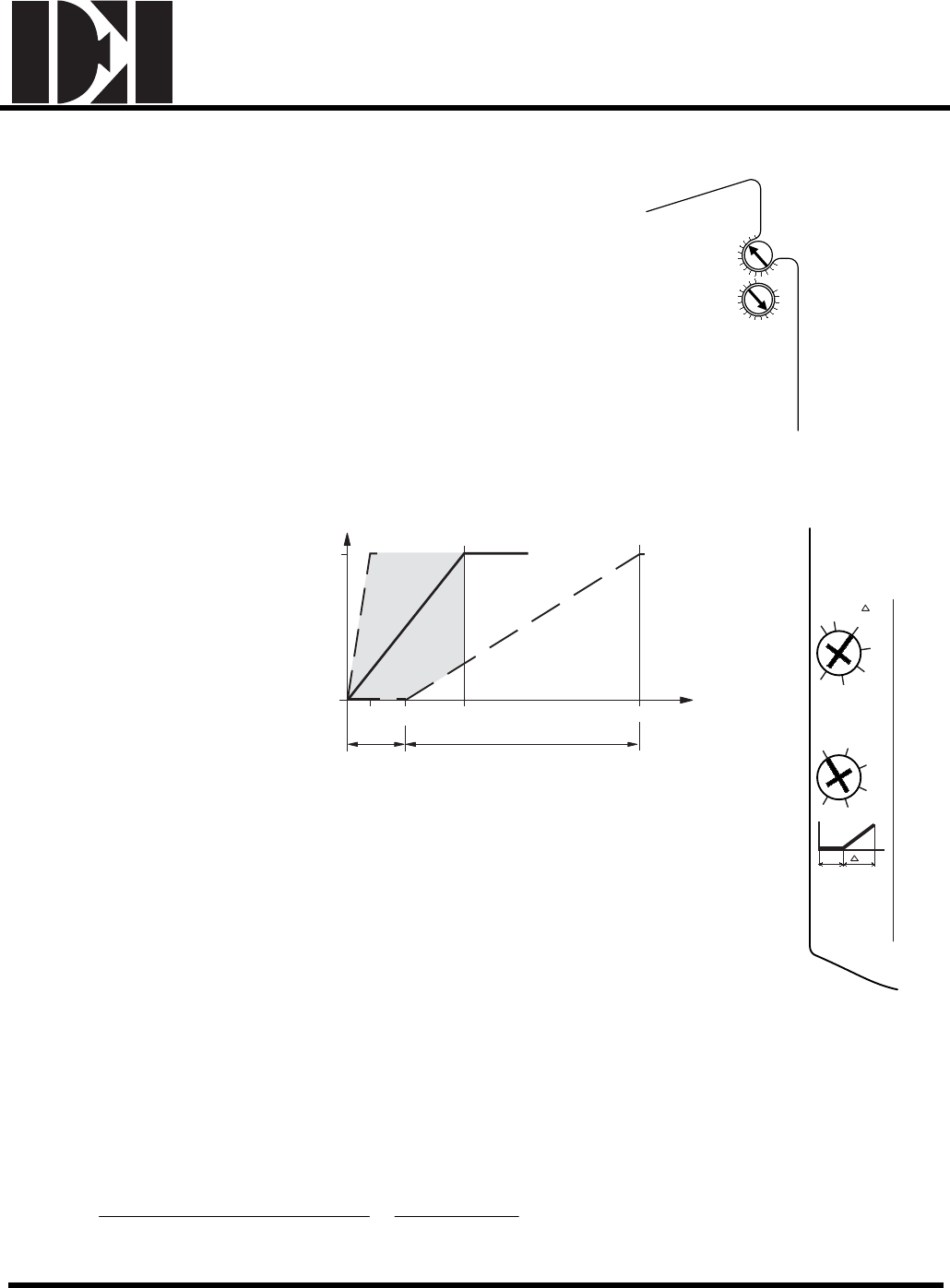

Zero Span Control Signal Adjustment (-ZS option)

The offset (start point) and

span of the control signal

can be adjusted. The offset,

U0, (start point) can be

adjusted between 0 to

5 VDC. The span, ∆U, can

be adjusted between 2 to

30 VDC.

100

0

U

O

∆

U (max. 30 V)

Y

U

(v)

Y

S

(%)

EA0411R1

2 5 10 35

2)1) 3)

Ys Mechanical positioning range

(100% = angle of rotation 90°)

Yu Control signal

U0 Offset (start point)

∆U Span

Examples above:

Ex. 1. U0 = 0V, ∆U = 2V The minimum working

range for Ys = 100%.

Ex. 2. U0 = 5V, ∆U = 30V The maximum working

range for Ys = 100%

Ex. 3. U0 = 0V, ∆U = 10V Factory setting

Offset, Uo

2

4

0

1

3

5

Span, U

30

2

15

10

5

20

25

Control

Signals

Uo

U

EA0287R1

Figure 17. The Minimum, Factory Setting, and Maximum

Control Signal Adjustment.

Figure 18. Setting for

10V Span, 0 Offset.

Example:

Open the actuator from 0% to 50% (45°) using a control signal of Umin = 2V to Umax = 10V.

Calculating the value of ∆U:

V16

50

2)(10 x 100

% in rotation of angle Working

min) Umax (U %] [ 100

U =

−

=

−

=∆

UL Doc. No. 129-272 EAI/EN-6 Dodge Engineering & Controls, Inc.

Rev. 5, Jan., 2005