Diesel Engine Engine Testing

96

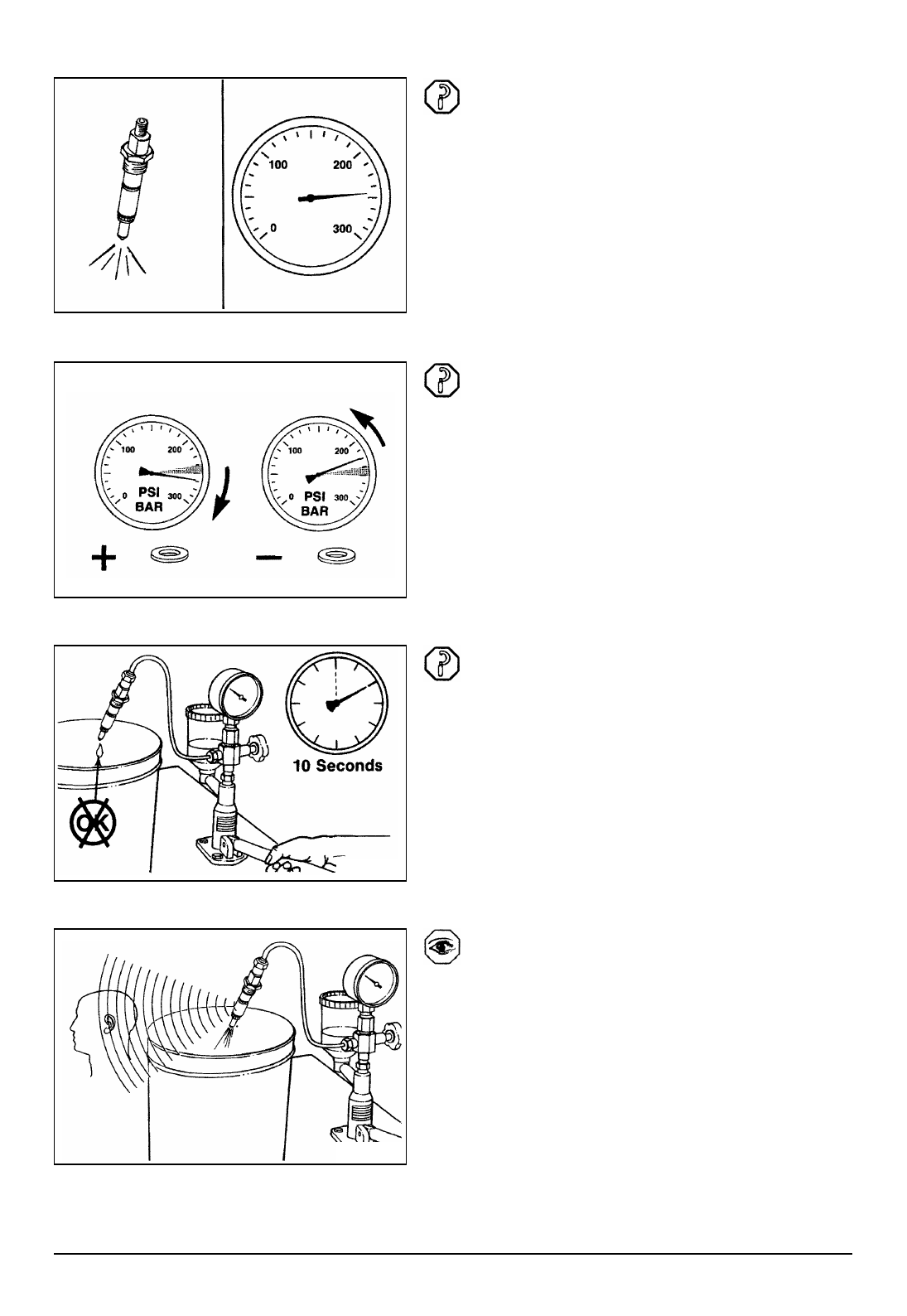

Check the opening pressure.

a. Open valve.

b. Operate lever at one stroke per second.

c. Read pressure indicated when spray begins.

If the opening pressure is out of specification,

disassemble the injector and change the shims in

order to change the opening pressure.

NOTE: .01 mm [0.0039 in] shim thickness equals

41 bar [595 psi].

Leakage Test

a. Open the valve.

b. Operate the lever to hold pressure 20 bar [290

psi] below opening pressure.

c. No drops should fall from the tip within 10

seconds.

Chatter Test

The chatter test indicates the ability of the needle

valve to move freely and correctly atomize the fuel.

An audible sound should be heard as the valve

rapidly opens and closes. A well optimized spray

pattern should be seen.

Used nozzles should not be evaluated for chatter at

lower speeds. A used nozzle can generally be used if

it passes the leakage test.

fi900de

fi900oa

fi900df

fi900dd