LF470/LF622

6

Wiring Precautions

(1) Connect the following two cables correctly:

1) signal cable (on the right facing the LF470)

2) excitation cable (on the left facing the LF470)

See figure3.

(2) Do not bend apply excessive force to these cables.

(3) DO1, DO2 (opt.), and DI (opt.) use the same

common terminal (COM). This COM can not

connect to other equipments which have their

own ground terminal. (Power supply for

connecting to DI or DO, etc…) Need to wire

separately.

Wiring Precautions (PROFIBUS or Modbus)

(1) For wiring path, avoid places near electrical

equipment that may cause electromagnetic

induction or electrostatic induction interference

(such as a motor, transformer and wireless

transmitter).

(2) Use a PROFIBUS-PA cable or a RS485 twist-pair

cable for signal cable. In addition, make sure to

use a shielded cable to improve noise resistance.

Furthermore, installation of signal cable in metal

conduit is recommended.

(3) General cables are designed for indoor use where

cables are not exposed to humidity, rain, etc.

When you install cables, make sure to check the

operating conditions such as the operating

temperature range of the cable by contacting its

manufacturer.

(4) When you carry out cable end treatment of cable,

use a dedicated cable stripper etc. so that the core

wire of the cable will not be nicked or damaged.

In addition, for cables, be careful of allowable

maximum bend diameter etc. (Basically, do not

install cables in a way cables are twisted or bent.).

(5) Consider installing a PROFIBUS-PA arrester in

the communication path of PROFBUS-PA so that

the electromagnetic flowmeter will not be affected

by lightning etc.

(6) The electromagnetic flowmeter is not equipped

with terminating resistors. Use the terminating

resistor unit for PROFIBUS-PA or junction box,

if necessary.

(7) Only one PROFIBUS-PA cable goes through a

cable gland of the Electromagnetic Flowmeter.

Please use the junction box at system

configuration.

(8) Install a terminator to flowmeter that connected to

end of Modbus network.

Piping Precautions

(1) Connect the fluid pipe to the pipe connection port

using a joint that matches the Rc (PT) female

screw. Use seal tapes when connecting the pipe to

the port to prevent a fluid leakage. Do not tighten

the connection screw too much.

(2) Design piping so that the detector’s pipe is always

filled with the fluid to be measured, whether the

fluid is flowing or not.

(3) The fluid to be measured must be held still in the

pipe when the LF470 is being adjusted. If the fluid

can not be stopped after the LF470 installation,

install a bypass pipe in parallel with the LF470

flowmeter.

Meter size

To select the meter size:

See Table 1 to 2 and find meter sizes within the

velocity of 0.1 to 10m/s (0.3 to 32.8 ft/s) for a

specified full-scale (measuring range high limit)

flow. Select one that has its full-scale velocity

between 1 and 3m/s (3.0 and 10 ft/s).

Note: Make sure the full-scale flow rate used for the

final planning stage stays within 10m/s (32.8 ft/s)

in terms of flow velocity.

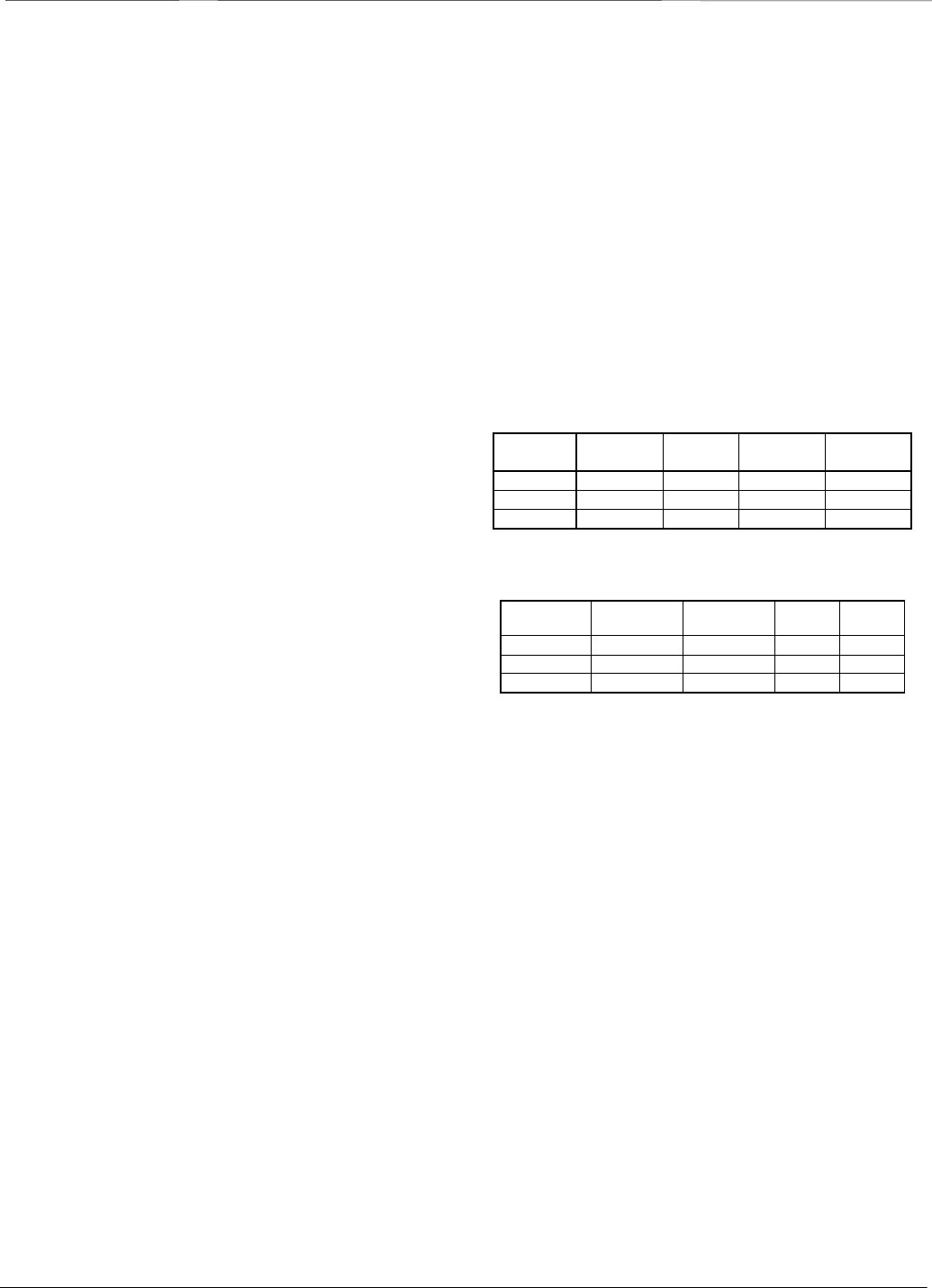

Table 1. Meter size and Flow Velocity(SI unit)

Unit:L/min

Meter size

(mm)

0.3m/s 1m/s 3m/s 10m/s

2.5 0.08835 0.2945 0.884 2.945

4 0.2262 0.7540 2.262 7.540

6 0.5088 1.6967 5.090 16.967

Table 2. Meter size and Flow Velocity (US unit)

Unit:gal/min

Meter size

(inch)

0.98 ft/s 3 ft/s 10 ft/s

32.8 ft/s

1/10” 0.02334 0.07115 0.2372

0.7781

1/6” 0.05975 0.1821 0.6071

1.992

1/4” 0.1344 0.4098 1.3660

4.482

About establishment environment

Do not store or install the flowmeter:

• Where there is direct sunlight.

• Where excessive vibration or mechanical shock

occurs.

• Where high temperature or high humidity

conditions exist.

• Where corrosive atmospheres exist.

• Places that can be submerged under water.

• Where there is a sloped floor. To put the flowmeter

temporarily on the floor, place it carefully with

something, such as a block, to support it so that the

flowmeter will not topple over.

In areas like the following, there may be the case that

infrared switches do not function correctly. (If these

are unavoidable, use an appropriate cover.)

(1) Where unit (operation panel) is exposed to direct

sunlight, reflection of light onto window pane and

diffused light reflection.

(2) Where smoke and steam may occur.

(3) Where exposed to direct snow, ice or mud.