EJL-142A

Field Intelligent Device Series

Electromagnetic Flowmeter

LF470/LF6

2

2

2.5,4,6mm (1/10",1/6”,1/4")

Introduction

The electromagnetic flowmeter uses Faraday’s Law of

electromagnetic induction to measure the process flow.

The device consists of two units: a detector, through

which the fluid to be measured flows and in which

low-level signals proportional to flow rates are

obtained; and a converter, which supplies excitation

current to the detector, and amplifies the signals from

the detector and then processes and converts the

signals into the 4–20 mA dc current signal. The LF470

is a small meter size detector designed to measure a

small amount of fluids containing substances such as

chemicals.

The wetted materials for the LF470 are corrosion

resistant ceramic and platinum electrodes and are

applicable to almost any kind of fluids. The LF470 is a

lightweight palm-sized detector.

Combining with a LF622

multifunctional converter

which has an improved noise-suppression circuit and

advanced algorithms. The LF470 is highly resistant to

noise and provides a stable output even for fluids

containing slurries. IR (Infrared) switches enable

parameter setting of the converter without removing

the cover. Flow direction can be set in either way, and

its unique 128 x 128 dot matrix LCD display allows

the LCD to be rotated electronically to 90, 180 and 270

degrees without opening the cover

The AF900 hand-held terminal (HART*

1

communicator) can be used to communicate with the

flowmeter from a remote place. PROFIBUS-PA*

2

or

Modbus*

3

interface is available as an option.

*1: HART protocol (Highway Addressable Remote Transducer) is a

communication protocol for industrial sensors recommended by the

HCF (HART Communication Foundation).

*2: PROFIBUS is the communication protocol for factory and process

automation that the PROFIBUS Organization recommends. Instead of

analog control with a conventional analog signal (4-20mA), it is

fieldbus which digitizes all signals. Flowmeters support

PROFIBUS-PA.

*3: Modbus is the communication protocol that Modicon Inc. developed.

Physical layer is RS485.

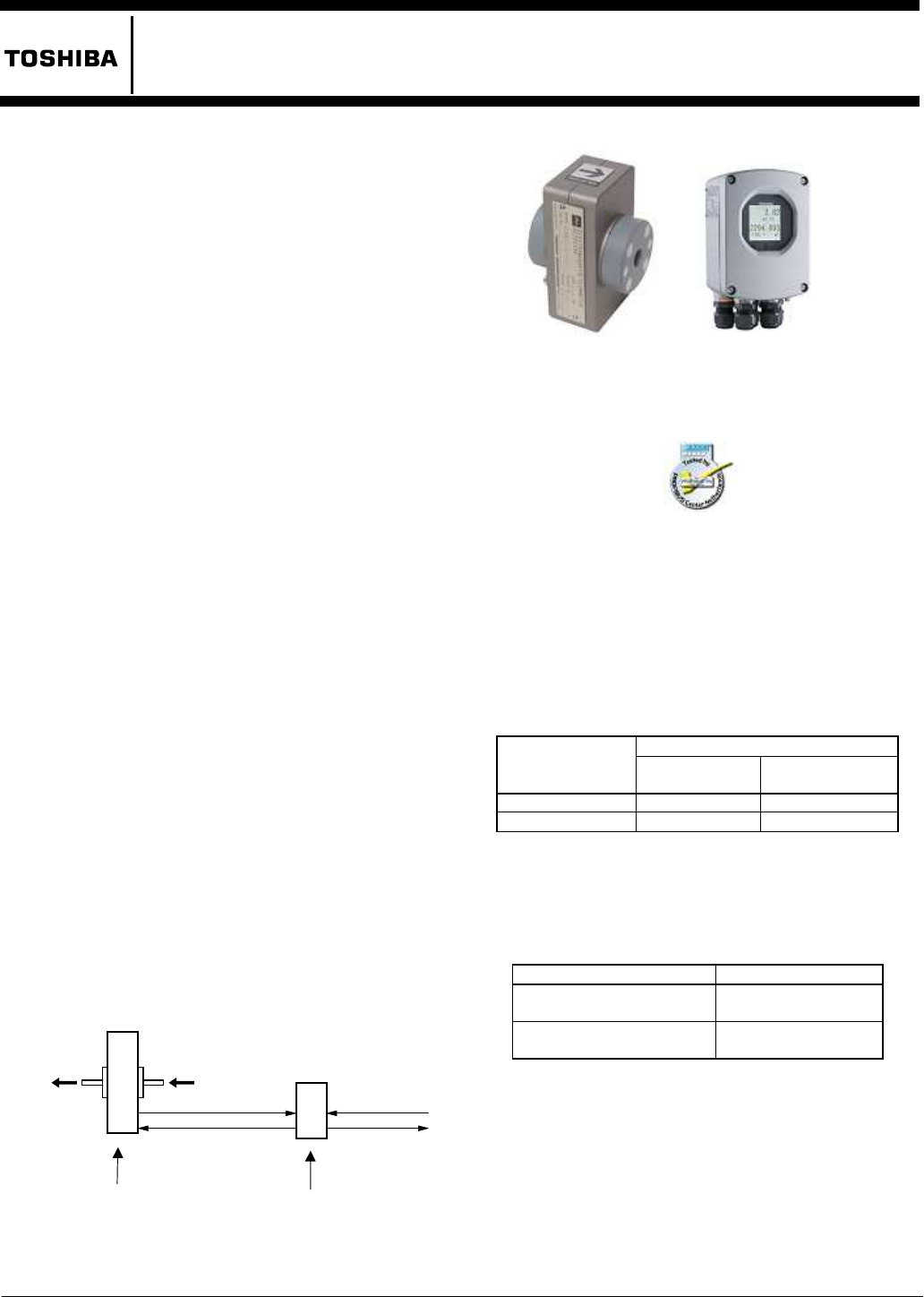

Figure 2. Electromagnetic Flowmeter

LF470/LF622

Specifications

Overall Specifications

Measurement range in terms of flow velocity:

0–0.3 m/s to 0–10 m/s. (0–1.0ft/s to 0–32.8ft/s).

Accuracy: The overall accuracy combined with the

LF622 converter is shown in the following table.

Accuracy Flow rate as a

percent of range

0.3-1.0m/s

(1.0-3.3ft/s)

1.0-10m/s

(3.3-32.8ft/s)

50 100 0.8% of FS

0.8% of rate

0 50 0.8% of FS

0.4% of FS

Note: The accuracy is measured under standard

operating conditions at Toshiba's calibration facility.

Fluid conductivity: 50µS/cm minimum

Fluid temperature:

Pipe connection material

Fluid temperature

Stainless steel and other metals 10 120

(

°

)

Polyvinyl chloride

(shock-resistant)

10 60

°

Ambient temperature: –10 to +60 °C (14 to 140 °F)

Structure: IP67

Power consumption:

When combined with the LF622 converter:

Standard:10W(14VA)

at AC100V and Excitation current:0.2A

MAX:15W (22VA)

Fluid to be

measured

Signal cable

Excitation cable

Power supply

4-

20mA dc output

and pulse output

LF622 Converter

LF470

Detector

Figure 1. Configuration Diagram

LF470

LF622

Certification number

Z01207