TJ10 User Manual ► 11

TROUBLESHOOTING

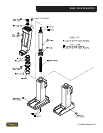

PUMPING HANDLE

A pumping handle is included with the Track Jack is de-

signed with a 4:1 safety factor. DO NOT use the pump-

ing handle for any other purpose. DO NOT substitute

other material for use as a pumping handle.

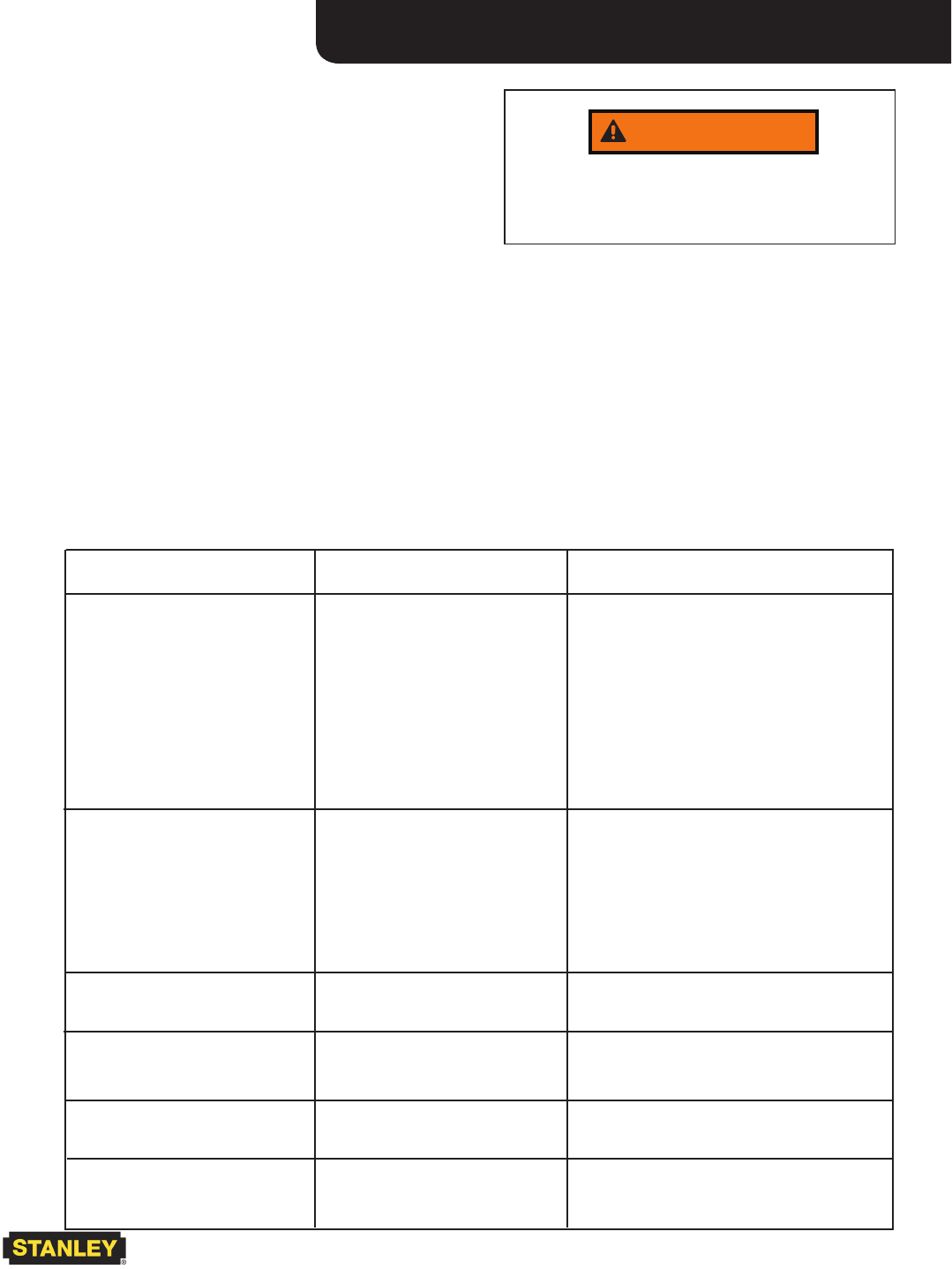

If symptoms of poor performance develop, the following chart can be used as a guide to correct the prob-

lem.

Because the Track Jack can be used for many different applications, this information is general in nature

anddoesnotaddressspecicuses.

PROBLEM CAUSE CORRECTION

Jack will not raise

A) Release valve not closed

Close the valve

B) Release valve ball not

seating properly

Havejackservicedbyaqualied

technician

C) Seal failure Havejackservicedbyaqualied

technician

Jack raises but will not hold Release valve ball not seat-

ing properly

Relief valve set too low or

Malfunctioning

Havejackservicedbyaqualied

technician

Seal failure Havejackservicedbyaqualied

technician

Jack only raises part way Hydraulicuidlevelislow Addhydraulicuid

Jackleakshydraulicuid Seal failure Havejackservicedbyaqualied

technician

Jack retracts slowly Air in the hydraulic system Purge air from the hydraulic system

Jack raises, but pulses and

hesitates

Air in the hydraulic system Purge air from the hydraulic system

4. Make sure personnel are clear of all items being

jacked before attempting to move anything.

5. Insert the jack handle into the handle socket and

pump until the desired separation has been obtained.

6. Remove the jack handle from the socket once the

moveable load reaches its desired separation.

7. To free the jack, open the release valve by turning it

counterclockwise. When the lift plate is clear, close

the release valve.

TROUBLESHOOTING

NEVER LIFT OR LOWER A LOAD HEAVIER THAN

THE LOAD RATING OF THE JACK. DAMAGE

TO THE JACK OR LOAD COULD RESULT FROM

IMPROPER USE OF THIS TOOL.

WARNING