MB156 User Manual ◄ 13

Always direct the down pressure force in a line toward

the point of tool contact with the work.

Moving rocks with the tool bit is another method of bind-

ing the tool bit. This practice should be avoided as it may

cause tool bit failure.

Rebar reinforced concrete introduces the problem of

concrete chunks being held together by the rebar after

the concrete has been broken. The best approach to this

problem is to use a chisel point tool which permits cut-

ting the rebar with the breaker. Another method is to pe-

riodically cut the rebar with an oxy-acetylene torch

BLANK FIRING

To understand “Blank Firing”, the operator needs to be

aware that the tool bit is able to drop down in the lower

body cavity, far enough so that the piston cannot strike it,

when the tool bit is not in contact with the work surface.

“Blank Firing” occurs whenever the breaker is operating

and the piston is not able to strike the tool bit solidly or

not strike the tool bit at all. “Blank Firing” accelerates

wear and tear on breaker and carrier components and

may result in failure of one or more components. Exces-

sive “Blank Firing” may be considered equipment abuse

and may result in voiding warranties.

Break-through or difcult surface contact results in

“Blank Firing” when the material being broken fractures

and the tool bit is no longer in “hard contact” with the

material but is still pushed high enough in the lower body

cavity so that the piston can strike it. In this position, the

piston strikes the tool bit and the tool bit, in turn, is driven

against the retaining pins because it is not in sufcient

contact with the material to be broken. The energy is ab-

sorbed by the retaining pins, other breaker components,

and the carrier boom components. “Blank Firing” of this

type can be experienced in trench work where obtain-

ing striking contact with the work surface is difcult or

the wrong tool bit is used, or in at rock work where the

operator fails to stop operation of the breaker when slip-

page, fracturing or material break-through occurs.

“Blank Firing” as a result of operator error occurs when

the tool bit is not in contact with the work surface to be

broken and is allowed to drop down in the lower body

cavity so that the piston is not able to strike it. Instead,

the downward movement of the piston will be stopped

by an internal oil cushion located at the bottom of the

piston’s stroke and the energy of the piston will be ab-

sorbed by breaker components and excavator boom

components. “Blank Firing” of this type can be experi-

enced when the operator fails to stop operation of the

breaker when the material fractures or material break-

through occurs, or during re-positioning of the breaker.

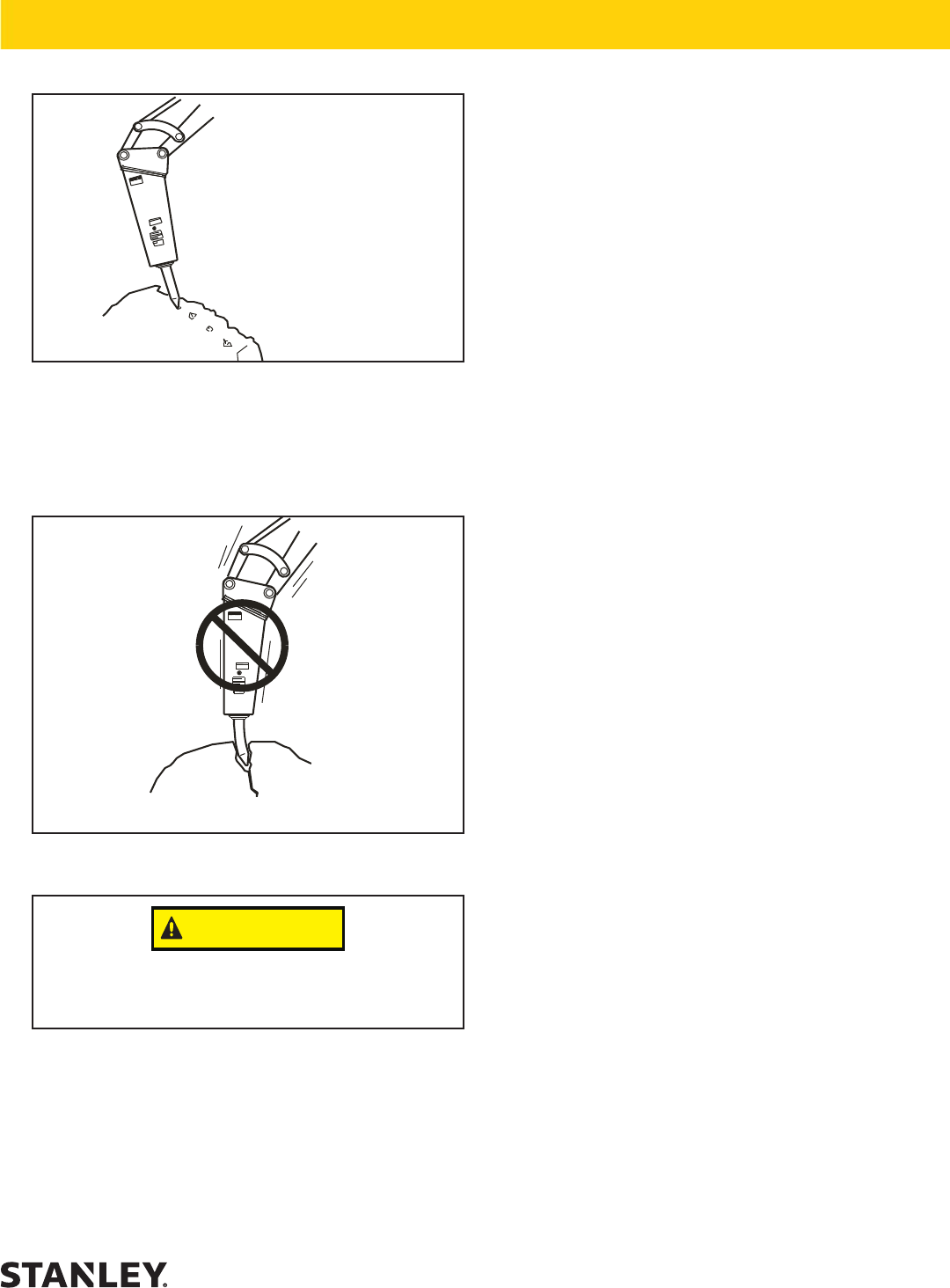

Scoring with the breaker

Figure 8. Scoring with the Breaker

Breaker tool binding can cause erratic breaker opera-

tion and premature wear on the tool shank. Breaker tool

binding is caused by failure to direct the down force in

the direction of the tool bit.

Breaker tool bit binding

Figure 9. Breaker Tool Bit Binding

CAUTION

Do not pry with bit and breaker. The tool bit may

break causing injury.

Excessive side force cocks the tool in its bore, prevents

proper movement and causes premature tool shank and

bushing wear. Since the breaker tool bit must be pushed

up into the breaker to operate, a binding tool prevents

the breaker from operating correctly. Binding also causes

the tool bit and tool bushings to seize and often results

in breakage of one or more breaker components.

OPERATION