19

SECTION 3 – MAINTENANCE

3.1 INTRODUCTION

To retain the quality of the Turf Cruiser™/Trail Cruiser™

utility vehicle, use genuine SNAPPER replacement parts

only. Contact a local SNAPPER dealer for parts and

service assistance. For the correct part or information,

always mention the model and serial number. SNAPPER

recommends returning the utility vehicle to an authorized

SNAPPER dealer annually for inspection and addition of

any new devices, which might upgrade the safety of the

machine. For the nearest SNAPPER dealer in your area,

check the Yellow Pages under the heading “LAWN

MOWERS”. For engine parts and service, look for the

engine manufacturer’s dealers under the heading,

“ENGINES – Gasoline”.

3.2 SERVICE - AFTER FIRST 5 HOURS

Routine maintenance is important to the performance

and life of your vehicle. Service performed properly and

at the recommended interval is essential. Refer to

Section “MAINTENANCE SCHEDULE” in this manual

and in the Engine Owner’s Manual. Carefully complete

all of the recommended service procedures.

IMPORTANT: Before working under a raised cargo

bed, the bed must be empty and the prop rod securely

latched.

3.2.1. Change Engine Oil

NOTE: The ServiceMinder is programmed to remind

operator to change oil after first 8 hours of use. Should

you choose instead to change oil after the first 5 hours

of operation, simply disregard the ServiceMinder

message.

1. Raise empty cargo bed and secure with prop rod.

2. Locate oil drain plug on engine at bottom front

center of crankcase. See Figure 3.1.

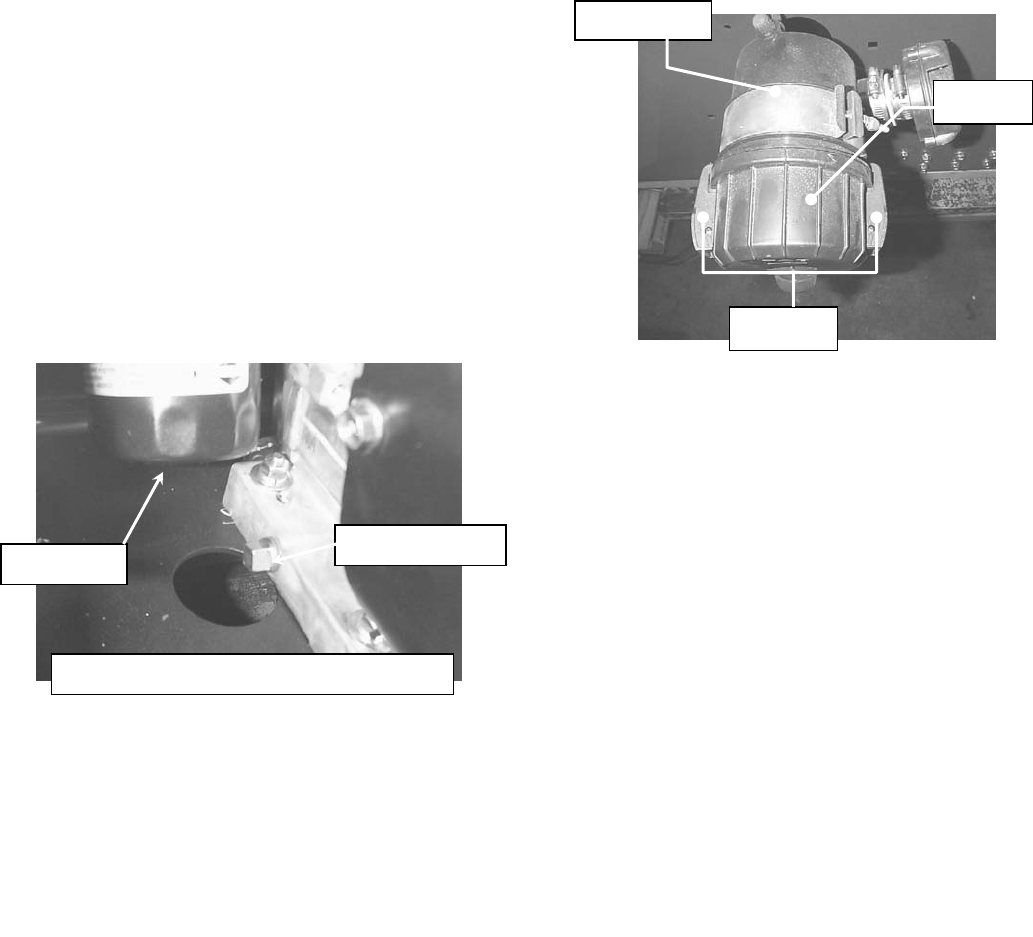

FIGURE 3.1

3. Place a 2 quart minimum capacity container

under the drain plug.

4. Loosen or remove oil fill cap on engine.

5. Turn drain plug counter-clockwise and remove.

Allow sufficient time for oil to drain completely.

6. Reinstall the oil drain plug. Torque plug to 12

ft-lb.

7. Fill engine crankcase to proper level with new oil.

Refer to the Engine Owner’s Manual for

crankcase capacity and oil specifications. Do not

overfill. The machine must be on a level surface

and the dipstick unthreaded when checking

engine oil level.

8. Lower cargo bed and latch securely.

IMPORTANT: Any oil spilled during draining or filling

must be cleaned off of the machine before operating.

Dispose of drain oil properly.

3.2.2. Service Engine Air Cleaner

The engine is equipped with a large capacity air

cleaner. Service and replacement intervals will vary

depending on operating conditions.

1. Locate engine air cleaner. Cover is retained with

two latches. Unsnap both latches and remove

cover. See Figure 3.2.

FIGURE 3.2

(Viewed from top, cargo bed removed)

2. Remove air filter element.

3. Clean inside of filter canister carefully - DO NOT

allow debris to enter intake tube.

4. Service element. Clean by tapping gently on firm

surface. Tapping will remove loose debris only. If

cartridge is damaged or dirty, REPLACE IT. DO

NOT oil the filter element or use pressurized air.

5. Place filter element into center of canister and

press firmly to seat fully.

6. Attach cover to canister. Make sure that both

latches are hooked on the flange on the canister,

the cover is secure and the duck bill valve is

located at the bottom. See Figure 3.3.

LATCHES

CANNISTER

COVER

OIL DRAIN PLUG

NOTE: HEAT SHIELD REMOVED FOR CLARITY.

OIL FILTER

22