Series 730 Instruction Manual

6 IM-73-E

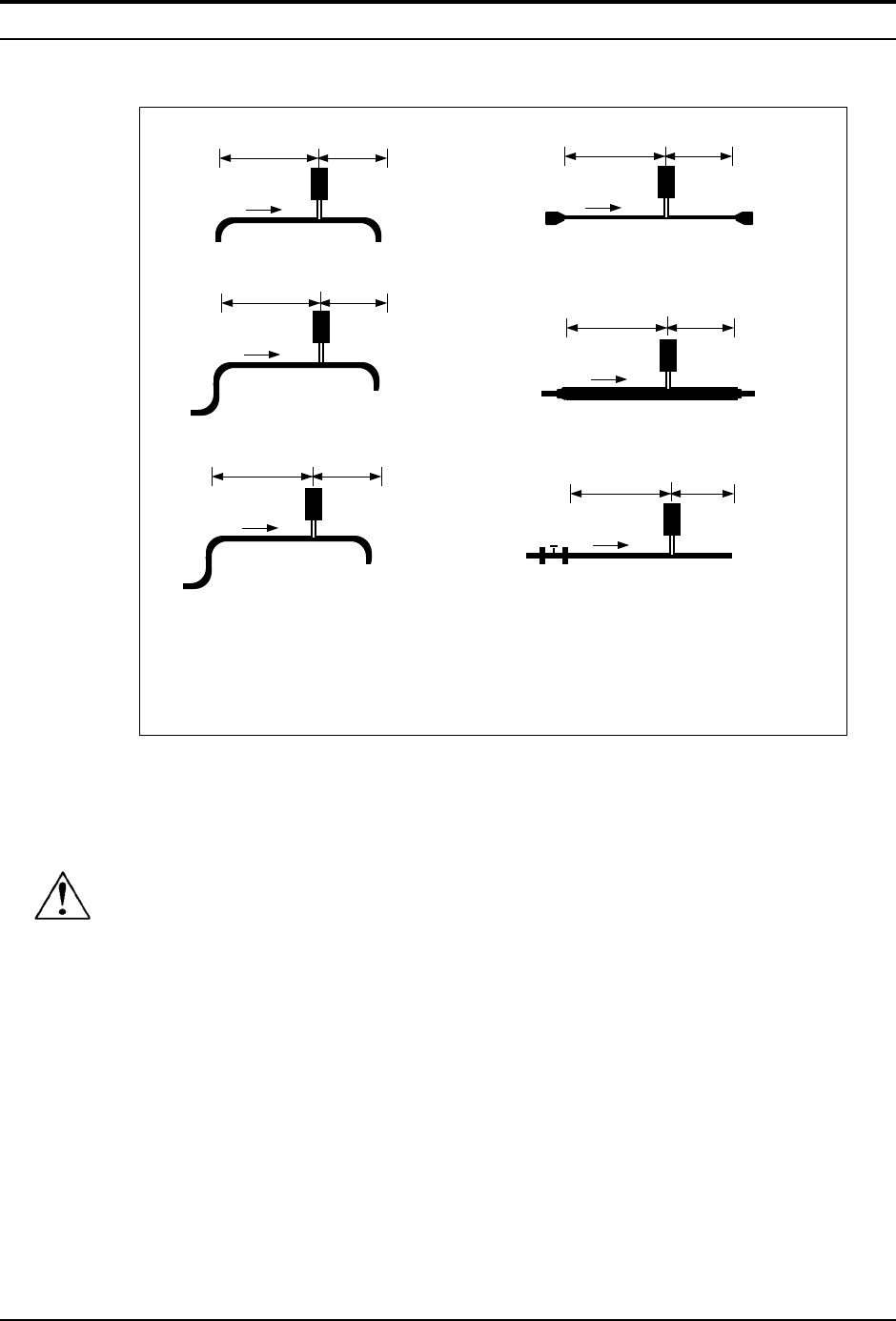

Flow meter

10 D 5 D

One 90° elbow before meter

Flow meter

15 D 5 D

Two 90° elbows before

meter in one plane

Flow meter

25 D 10 D

Two 90° elbows before meter out

of plane (if three 90° bends present,

double recommended length)

Flow meter

10 D 5 D

Reduction before meter

Flow meter

20 D 5 D

Expansion before meter

Regulator or valve partially closed before meter

(If valve is always wide open, base length

requirements on fitting directly preceding it)

Flow meter

25 D 10 D

D = number of diameters of straight pipe required between the disturbance and

the flow meter (upstream); and, number of diameters of straight pipe required

downstream of the flow meter

Flow

Flow

Flow

Flow

Flow

Flow

Figure 2. Recommended Pipe Length Requirements for Installation

Installation

The following instructions are general in nature and intended for

guideline purposes only.

1. Turn off the flow of process gas. Verify that the line is not

pressurized.

2. Confirm that the installation site meets the minimum upstream

and downstream piping requirements.

3. Position the meter with the flow direction arrow pointing down-

stream in the direction of flow.

4. Tighten fittings until leak tight (refer to published standards for

specific recommendation).

5. Check the system’s entire flow path thoroughly for leaks.

Caution!

All flow meter connections

and fittings must have the

same or higher pressure

rating as the main pipeline.