Series 730 Instruction Manual

IM-73-E 11

Product Specifications

Operating Specifications

Gases Most non-combustible, non-corrosive gases

Mass Flow Rates

Mass Flow Rate for Air

(1)

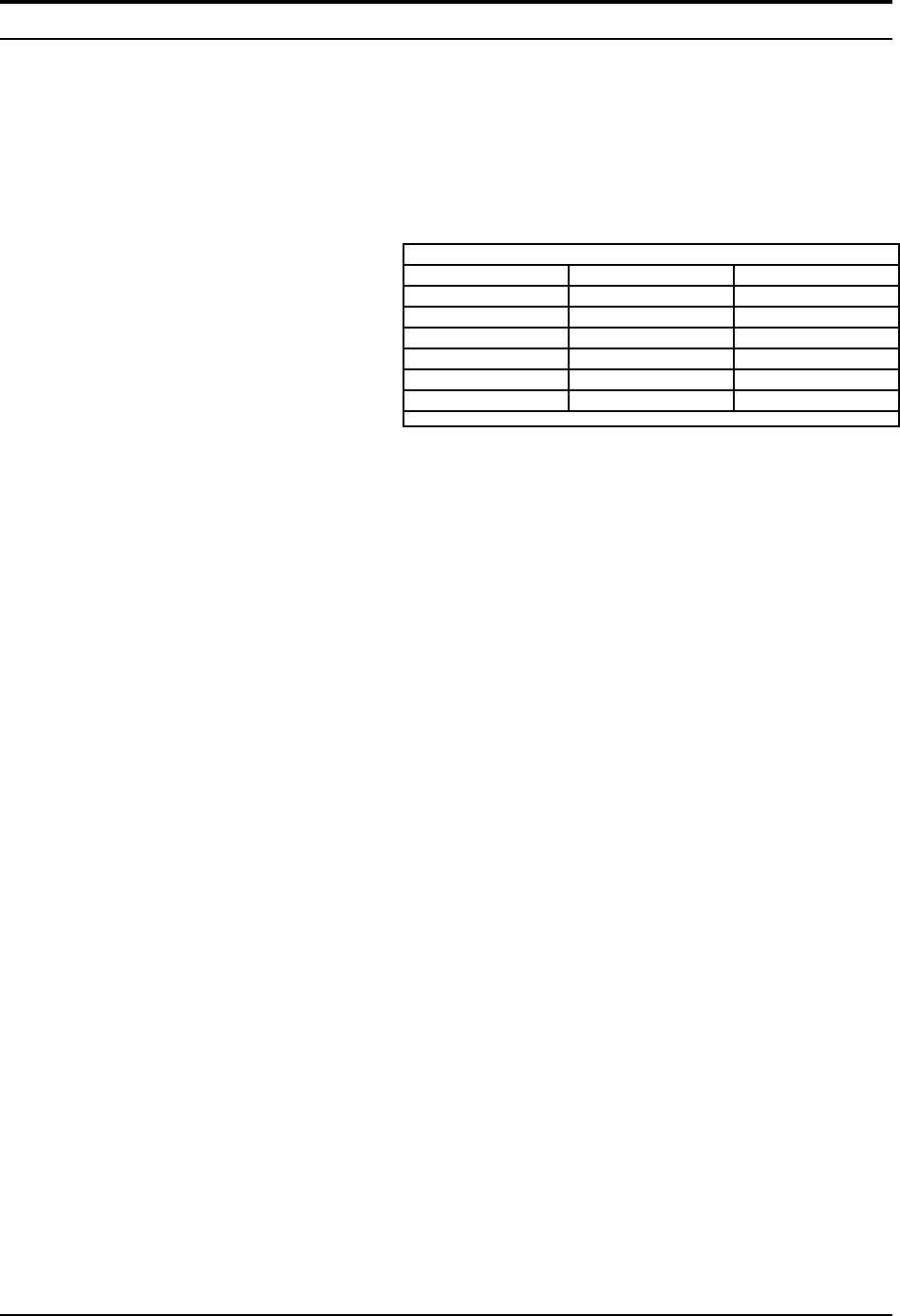

NPT Size Minimum Range Maximum Range

1/4-inch 0–0.035 scfm 0–4.5 scfm

1/2-inch 0–0.5 scfm 0–12 scfm

3/4-inch 0–1 scfm 0–25 scfm

1 1/4-inch 0–2 scfm 0–50 scfm

2-inch 0–5 scfm 0–125 scfm

3-inch 0–10 scfm 0–250 scfm

(1) Contact factory for ranges of other gases

Gas Pressure 150 psig (10 barg)*

*Maximum gas pressure is determined by the mechanical process connections, as well as, the ap-

plication conditions. Mechanical limitations are shown above, please consult factory for application

limitations.

Pressure Drop Negligible

Gas & Ambient Temperature Gas.............................14° to 176°F (–10° to 80°C)

Ambient......................32° to 120°F (0° to 50°C)

Leak Integrity 1 X 10

-2

atm cc/sec of helium maximum

Power Requirements 15 or 24 VDC, 300 mA

Output Signal Linear 0-5 VDC or 0-10 VDC proportional to mass flow rate, 1000 Ohms

minimum load resistance; or, linear 4-20 mA proportional to mass flow rate,

400 Ohms maximum resistance

Performance Specifications

Accuracy ± 1% of full scale + 0.5% of reading over 32 to 120°F (0 to 50°C) and 5 to 30

psia (0.3 to 2 barg)

Repeatability ± 0.2% of full scale

Temperature Coefficient ± 0.02% of reading per °F within ± 50°F of customer specified conditions

± 0.03% of reading per °F within ± 50°F to 100°F of customer specified conditions

±0.04% of reading per °C within ± 25°C of customer specified conditions

±0.06% of reading per °C within ± 25°C to 50°C of customer specified conditions

Pressure Coefficient Negligible within ±50 psig (3.4 barg) of customer specified conditions

(Special calibration required for higher pressures)

Response Time 200 milliseconds to 63% of final velocity value

Physical Specifications

Wetted Materials Anodized aluminum or 316 stainless steel flow body

Glass-coated sensor; epoxy; Viton O-rings

Enclosure Anodized aluminum NEMA 2

Painted cast aluminum NEMA 4