STOPPING

I_) Move equipment control or any ignition stop switch on engine

to STOP or OFF (see equipment manufacturer's instructions).

(_) Push stop switch (see Figure 1) located next to spark plug on

engine against spark plug and hold it inthis position until engine

is completely stopped.

(_) AFTER ENGINE IS STOPPED:

_I=A. DISCONNECT SPARK PLUG WIRE FROM SPARK PLUG

AND KEEP IT AWAY FROM SPARK PLUG.

_B. TURN IGNITION SWITCH KEY (IF SO EQUIPPED) TO

"OFF" POSITION AND REMOVE KEY FROM SWITCH.

A

J

THIS WILL REDUCE THE POSSIBILITY OF UNAUTHO-

RIZED STARTING OF ENGINE WHILE EQUIPMENT IS

NOT IN USE.

NEVER STORE ENGINE WITH FUEL IN TANK INDOORS

OR IN ENCLOSED, POORLY VENTILATED AREAS

WHERE FUEL FUMES MAY REACH AN OPEN FLAME,

SPARK OR PILOT LIGHT AS ON A FURNACE, WATER

HEATER, CLOTHES DRYER OR OTHER GAS APPLI-

ANCE.

MAINTENANCE

_kWARNING: TEMPERATURE OF MUFFLER AND NEARBY

AREAS MAY EXCEED 15g°F(65°C). AVO D THESE AREAS.

(_ CHECK OIL LEVEL:

Checkoilleveleveryfive(5) operatinghoursoreachtimeengine

is used.See "2CHECK OIL LEVEL"in "BEFORE STARTING"

on Page 1.

(_) CHANGE OIL:

Change oil after first two (2) operating hours and every 25

operatinghoursthereafter,moreoftenifoperated in extremely

dustyordirtyconditions. Changeoil whileengine isstillwarm

from recentrunning.

A. Positionequipmentsoengineoildrainplugis lowestpointon

engine(see Figure1).

B. Remove oildrainplugand oil fill plugto drain oil.

C. Replaceoil drainplugand tightensecurely.

D. Fill oil sump with recommendedoil. See "OIL & FUEL

RECOMMENDATIONS" and=CHECKOIL LEVEL"on Page

1.

E. Replace oil fill plug and tighten securely.

F. Wipe up any spilled oil.

MAINTENANCE (Continued)

2. PAPER FILTER:

DO NOT ATTEMPT TO CLEAN OR OIL FILTER.

Replace once a year or every 100 operating hours

more often if used in extremely dusty conditions.

Replacement filters are available at any Sears Roe.

buck and Co. (or Sears Canada, Inc.) Service Center

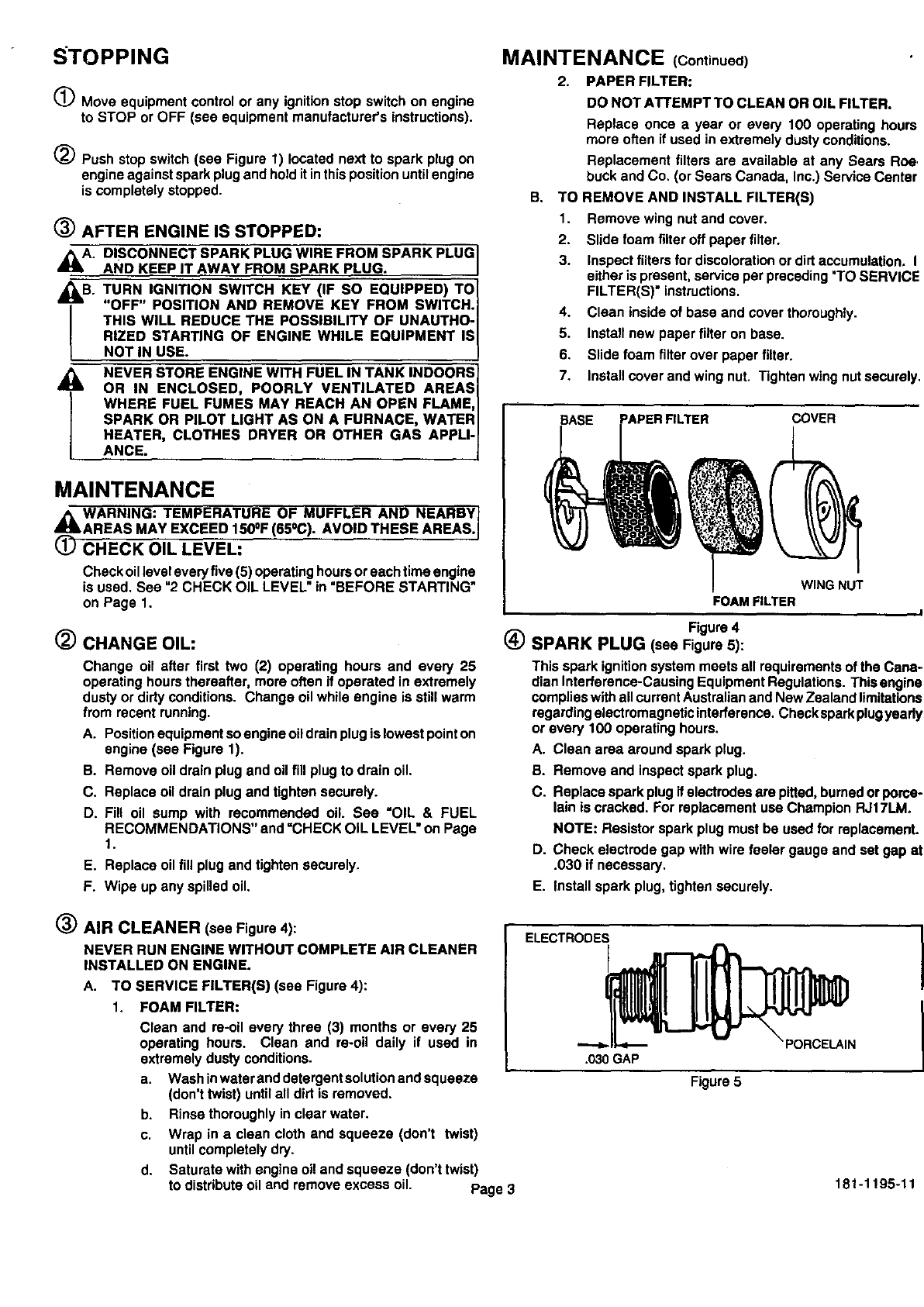

B. TO REMOVE AND INSTALL FILTER(S)

1. Remove wing nut and cover.

2. Slide foam filter off paper filter.

3. Inspect filters for discoloration or dirt accumulation. I

either is present, service per preceding "TO SERVICE

FILTER(S) =instructions.

4. Clean inside of base and cover thoroughly.

5. Install new paper filter on base.

6. Slide foam filter over paper filter.

7. Install cover and wing nut. Tighten wingnut securely.

BASE

COVER

WING NUT

FOAM FILTER

Figure4

(_ SPARK PLUG (see Figure 5):

Thisspark ignitionsystemmeetsall requirementsofthe Cana-

dianInterference-CausingEquipmentRegulations.Thisengine

complieswithallcurrentAustralianandNewZealandlimitations

regardingelectromagneticinterference.Checksparkplugyeady

orevery 100 operatinghours.

A. Clean area aroundspark plug.

B. Removeand inspectsparkplug.

C. Replacesparkplugifelectrodesare pitted,bumedorporce-

lainis cracked.For replacementuseChampionRJ17LM.

NOTE: Resistorsparkplugmustbe usedfor replacement.

D. Check electrodegap withwire feeler gaugeand set gap at

.O3Oifnecessary.

E. Installsparkplug,tightensecurely.

(_ AIR CLEANER (see Figure 4):

NEVER RUN ENGINE WITHOUT COMPLETE AIR CLEANER

INSTALLED ON ENGINE.

A. TO SERVICE FILTER(S) (see Figure 4):

1. FOAM RLTER:

Clean and re-oil every three (3) months or every 25

operating hours. Clean and re-oil daily if used in

extremely dusty conditions.

a. Wash inwater and detergent solution and squeeze

(don't twist) until all dirt is removed.

b. Rinse thoroughly in clear water.

c. Wrap in a clean cloth and squeeze (don't twist)

until completely dry.

d. Saturate with engine oil and squeeze (don't twist)

to distribute oil and remove excess oil. Page 3

ELECTRODES

.030 GAP

Figure 5

181-1195-11