96

MAINTENANCE

Suspension Maintenance

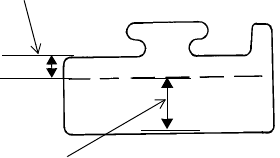

n Rail Slide Wear

For ease of inspection, all

Polaris rail slides have a

wear limit indicator groove

to indicate the minimum per-

missible slide thickness.

Replace the rail slides if they

are worn to the top of the

groove at any point along

their length. Failure to do so

may result in permanent

damage to the track or rails.

Suspension Inspections

Loose nuts and bolts can reduce your snowmobile’s reliability and cause

needless repairs and down time. Before beginning any snowmobile trip,

a visual inspection will uncover potential problems. Check the follow-

ing items on a weekly basis or before any long trip:

n Check suspension mounting bolts for tightness.

n Check rear idler wheel bolts for tightness. See page 91.

n Check rear idler adjusting bolt locknuts for tightness.

n Check front torque arm limiter strap condition.

n Check rail slide condition.

n Check track tension. See page 90.

n Lubricate/grease all suspension components. See page 66.

n Check ski runner/skag condition. See page 95.

n Check ski spindle bolts for tightness.

n Check tie rod end nuts for tightness.

Replace when

worn to top of

groove

Minimum

Thickness