64

WINCH GUIDE

Winch Cable Care

1. The life of a cable is directly related to the care it receives. The wire

cable on a new winch (and any replacement cables) must be re-

spooled under a minimum of a 100-lb. (45.4-kg) load before use.

Failure to do this will result in cable damage.

2. Inspect all cable before use. Mashed, pinched, frayed or kinked

areas severely reduce the load-carrying capability. Replace dam-

aged cable promptly.

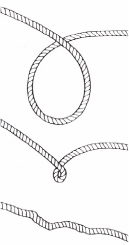

3. Prevent kinks before they occur.

A. This is a start of a kink. Straighten

the cable before using it.

B. The cable was pulled and the loop

has tightened to a kink. The cable

is now permanently damaged and

should not be used.

C. The result of kinking is that each

strand pulls a different amount of

load, causing the strands under the

greatest tension to break. This

reduces the load capacity of the

entire cable.

4. Before re-spooling, remove all load from the cable. Hold the han-

dlebar switch lead in one hand and the cable in the other. Move

away from the vehicle as far as the switch will allow. Activate the

switch, walk in several feet of cable, then release the switch. Repeat

this process until the re-spooling is complete.

CAUTION! To avoid injury, always release the switch before your hand comes

within four feet of the fairlead (the physical opening through which the cable

passes).

5. Be sure the cable is distributed evenly and tightly on the drum. A

loosely wound drum may allow the cable to work its way down into

the layers of cable on the drum and become wedged.

6. Do not grease or oil the cable. Doing so causes dirt contamination

that will reduce the life of the cable.

A

B

C