89

MAINTENANCE

Track Maintenance

If the track needs adjustment (continued):

8. Repeat measurement on the other side of the track.

NOTE: Check more frequently when machine is new.

9. Start the machine and slowly rotate the track at least five

revolutions. Let the track come to a stop (do not apply brakes).

10. Check track alignment (see page 89) and a djust as necessary.

11. Tighten locknuts (A).

12. Tighten idler shaft bolts (D) and torque to 35 ft. lbs. (47.5 Nm).

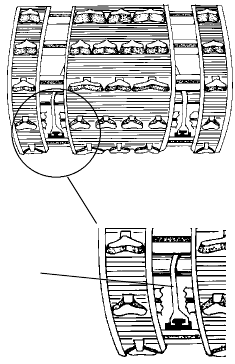

n Track Alignment

Periodically check that the track is

centered and running evenly on the

slide rails. Misalignment will cause

excessive wear to the track and slide

rail.

1. Safely support the rear of the

machine with the track off the

ground.

2. Start the engine and apply a small

amount of throttle until the track

turns slowly at least five complete

revolutions. Stop the engine and

let the track come to a stop (do not

apply brakes).

3. Inspect track alignment by looking

through the track window to make

sure the rails (A) are evenly

spaced on each side. If the track runs to the left, loosen left

locknut and tighten the left adjusting bolt. If the track runs to the

right, loosen right locknut and tighten the right adjusting bolt.

4. After adjustments are complete, tighten locknuts and torque idler

shaft bolts to 35 ft. l bs. (47.5 Nm).

5. Repeat steps 2 and 3 to verify proper alignment.

A