1-2

This manual contains detailed operating instructions for all

aspects of the FD6000 instruments. The following condensed

instructions are provided to assist the operator in getting

the instrument started up and running as quickly as

possible. This pertains to basic operation only. If specific

instrument features are to be used or if the installer is

unfamiliar with this type of instrument, refer to the

appropriate section in the manual for complete details.

1. TRANSDUCER LOCATION

A. In general, select a mounting location on the piping

system with a minimum of 10 pipe diameters (10 X the

pipe inside diameter) of straight pipe upstream and 5

straight diameters downsteam. See Table 2.1 for

additional configurations.

B. On horizontal pipe, select a position that is between 2

and 4 o’clock on the pipe, with 12 o’clock representing

the top. Installations on vertical pipe should be made

in an area where the flow moves from bottom to top—

ensuring a full pipe of liquid.

2. PIPE PREP ARATIO N AND TR ANSDUCER

MOUNTING

A. The piping surface, where the transducers are to be

mounted, needs to be clean and dry. Remove loose

scale, rust and paint to ensure satisfactory acoustical

bonds.

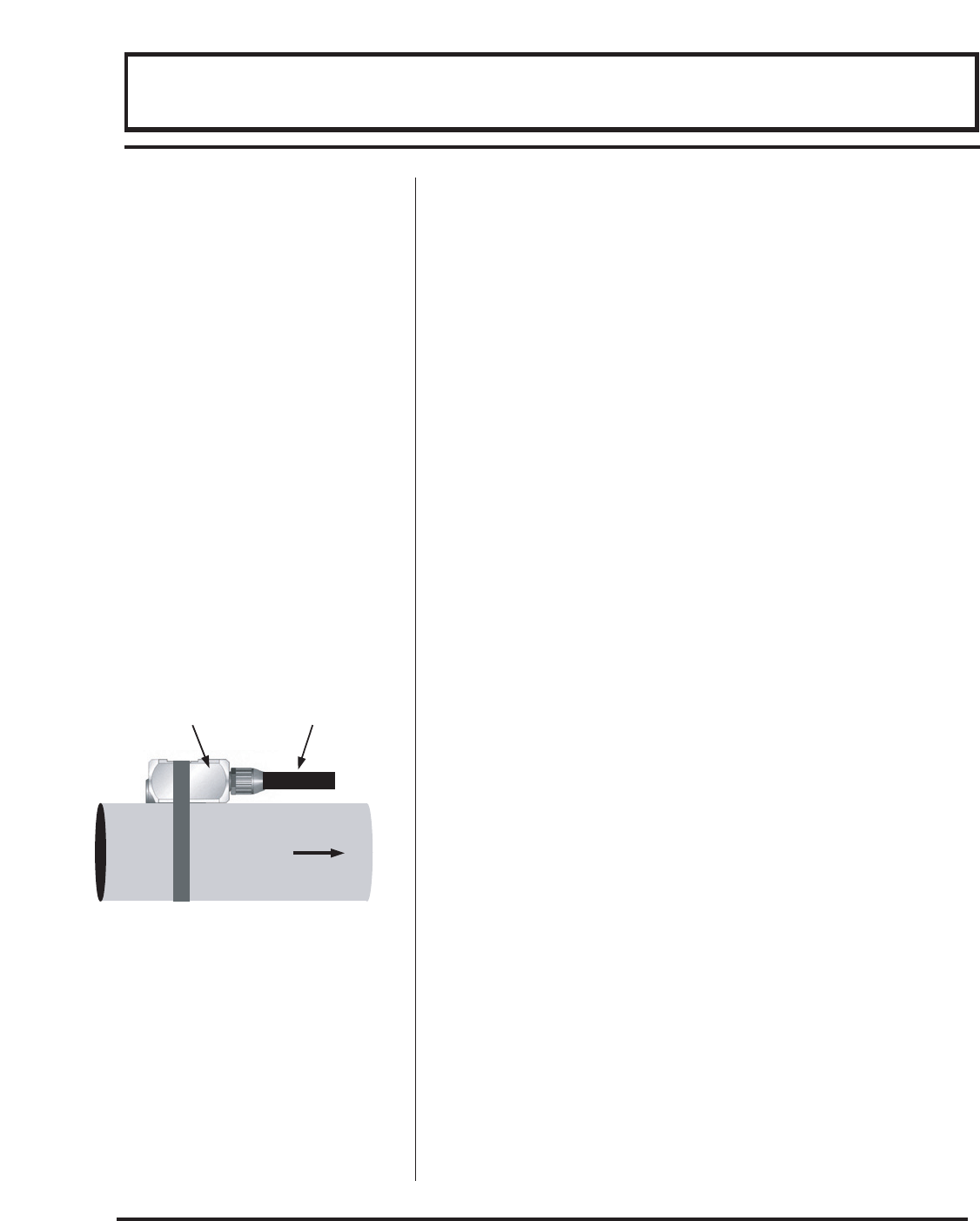

B. Loosely wrap the appropriate length of strap around

the pipe at the location determined in Step 1. Refer to

Figure 1.1 for proper orientation of the transducer. For

greatest accuracy, point the cable of the transducer in

the primary flow direction.

C. Apply a liberal amount of couplant onto the transducer

face. Place the transducer onto the pipe ensuring

square and true placement. If an RTV type of

couplant (requiring curing time) was utilized, allow

sufficient time for curing before applying power to the

instrument or moving the cable.

PART 1 - QUICK START

General

FLOW

Figure 1.1

Top View of Pipe

Transducer Cable