Refer to Diagrams 1 and 3: Basic Wiring Hookup for

correct connections to your engine.

Diagram 2 shows wire colors that correspond to the A88

plug and hookup wire, in the event of two colors the first

color is the primary color and the other is a tracer color.

Diagram 4 identifies the A88-F wiring terminals.

Step No. 1, Pickup:

Determine the type of pickup to be used and connect

it to the controller as illustrated in the basic wiring

hookup.

Step No. 2, Starter Solenoid:

Determine the type of starter solenoid used on your

engine. In most cases it will be of the source type, that

is, one side of the pull in coil is connected to ground and

and the other has to be connected through the ignition

to positive. Do not connect the controller output directly

to the starter, always use a starter slave solenoid.

Step No. 3, Ignition:

The type of ignition must be determined and wired

accordingly. Most later models will be of the CDI type.

Step No. 4, Start/Stop

Select the type of Start/Stop control needed and wire

accordingly. If a close to run and open to stop is used

be sure and connect the brown/white and the

grey/white together. On the A-88-F connect terminals

16 and 17. It is recommended that the alarm before

start be used for safety.

Step No. 5, Choke:

If a choke or pressure release feature is needed con-

nect the choke solenoid to battery positive then to

terminal 3 of the A-88-F or to the violet wire of the A-88.

Step No. 6, Shutdown:

Connect the shutdown circuits. The spare should be

marked or labeled on the blank space.

Step No. 7, Time Delay:

This system has a 60 second built-in time delay for

customer use. If the appropriate inputs are grounded, it

times out after the crank disconnect light comes on.

Step No. 8, Clutch or Warmup Operation:

If a warm up feature is desired see Section IV:

Optional Hookups paragraph 5

WARM UP.

Step No. 9, Crank disconnect adjustment:

To adjust the crank disconnect, disconnect the ignition

wire or leave the fuel cut off. That will let the engine

crank but not start.

Turn the crank disconnect control fully clockwise (15

turns). This control does not have a stop and it does

not hurt it to turn it more than 15 turns.

Place the the crank and rest time switch in the 10 or

15 second position. Switch the controller in the test

position. With the engine cranking, rotate the control

counter-clockwise until the starter drops out. Notice

that the engine will crank longer the first time.

When the starter kicks out, rotate the control clock-

wise for approximately 1(one) turn. The crank

disconnect is now set.

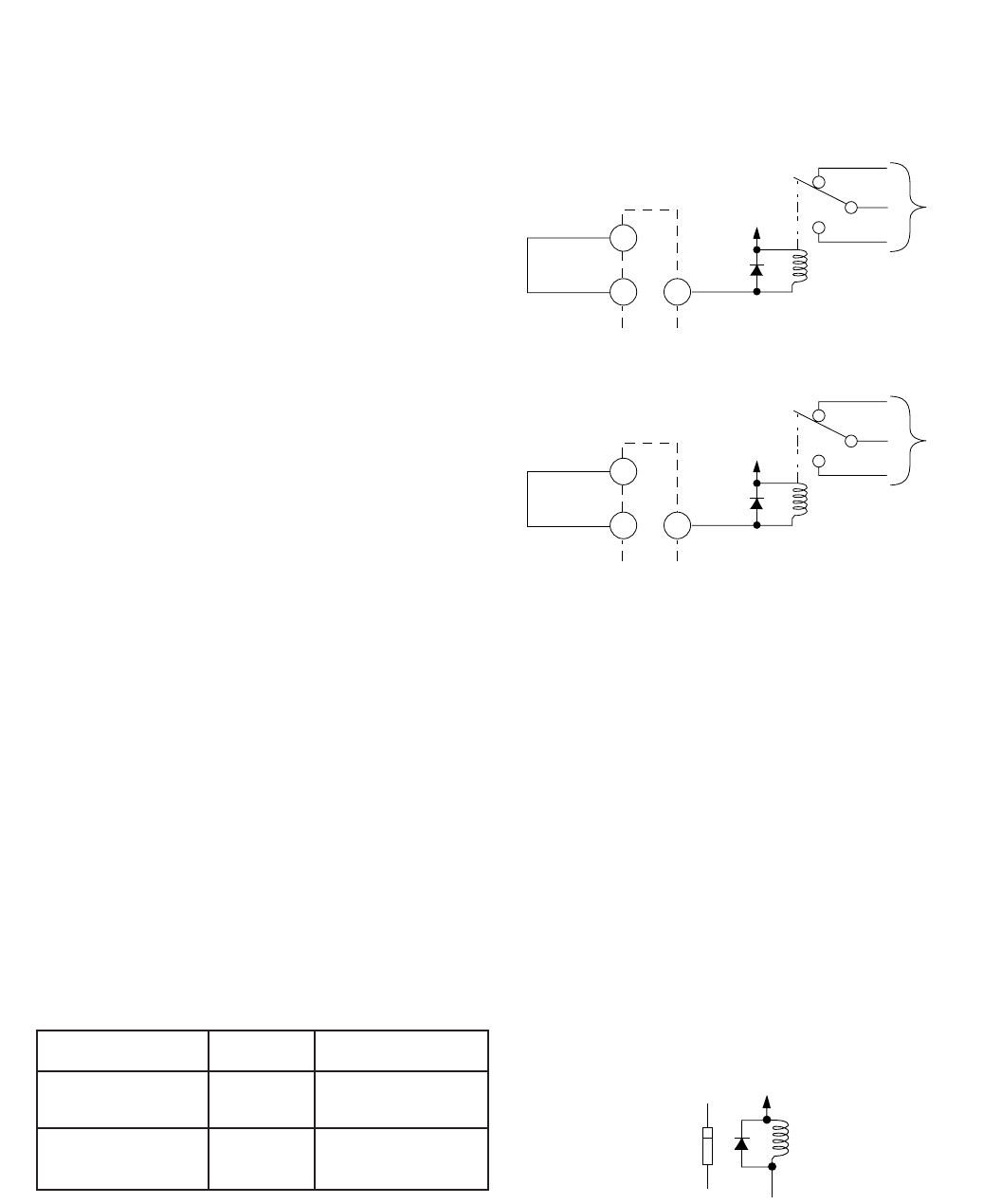

NOTE: When installing relays or solenoids that are

controlled by this controller always install a diode directly

across the coil windings to help eliminate the back EMF.

SECTION V: OPERATION

Batt.+

To

Clutch

Control

Orange

Violet/White

Yellow

Slave

Relay

Diode

Batt.+

18

9 19

To

Clutch

Control

Slave

Relay

Diode

A88

A88-F

Clutch activates approximately 90 seconds after

engine has started—pulls in after engine stops.

Clutch activates approximately 90 seconds after

engine has started—pulls in after engine stops.

Input Delay Output

60

seconds

60

seconds

Orange wire

Sinks to ground

Terminal 19

Sinks to ground

A88 ground

violet/white wire

A88-F ground

Terminal 9

+

Diode

Solenoid

or

Coil

5