PAGE 14 — MT-86D — PARTS & OPERATION MANUAL — REV. #1 (08/19/04)

5. Operation

5-1. Move the throttle lever quickly from the IDLE to OPERATION

position to start tamping action. DO NOT move the throttle lever

slowly as this may cause damage to the clutch or spring box.

5-2. The tamping rammer is designed to tamp the ground 700

times per minute at an engine speed of 3,300 rpm. Increasing

the engine speed above the recommended rpm will not increase

the rammer effectiveness. Impact will actually decrease because

a resonance is created rather than a tamping effect, and damage

to the unit can result.

5-3. The rammer can be warmed by quickly moving the throttle

lever from the OPERATION to the IDLE position several times

until the rammer operates smoothly.

5-4. The tamping rammer is designed to travel forward while

tamping. To increase travel speed, pull back slightly on the

handle so that the rear of the foot contacts the soil first.

5-5. To stop tamping, quickly move the throttle lever from the

OPERATION to IDLE position. Do not move the lever slowly as

irregular action and damage may result.

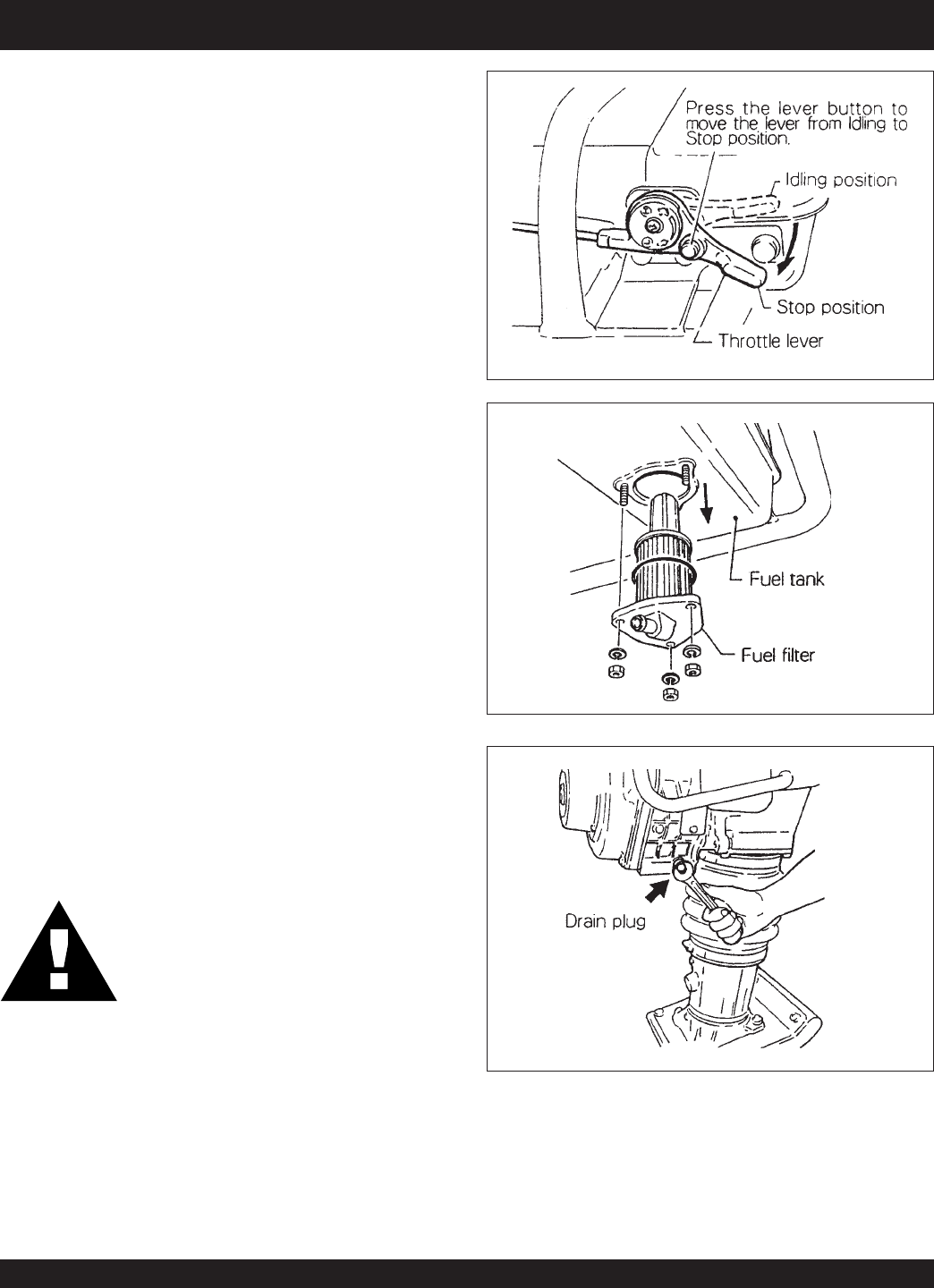

6. Stopping the Engine

6-1. Move throttle lever quickly from idle to STOP while pressing

the throttle lever button. Run the engine for three minutes at idle

speed to allow for proper cool down. Following the above

procedures will prevent improper cylinder lubrication caused

by a overheated engine. (Fig. 6)

7. Service

CAUTION:

Flammable Liquid: When refueling, stop engine and allow it

to cool.. Do no smoke or allow work to be

performed in the immediate area. Fire or

explosion could result from flames or sparks,

or if fuel is spilled on a hot engine.

Moving Parts: Shut down the engine before

performing service or maintenance functions.

Contact with moving parts can cause serious injury.

High Temperatures: Allow machine and engine to cool before

performing service or maintenance functions. Contact with hot

components can cause serious burns.

Fig. 6

Fig. 8

Fig. 7

MT-86D — OPERATION