PAGE 38 — HHXD5 RIDE-ON TROWEL • OPERATION MANUAL — REV. #2 (05/04/12)

MAINTENANCE

Look at the machine while it is running, do the guard

rings “rock up and down” relative to the ground?

Do the pitch control towers rock back and forth?

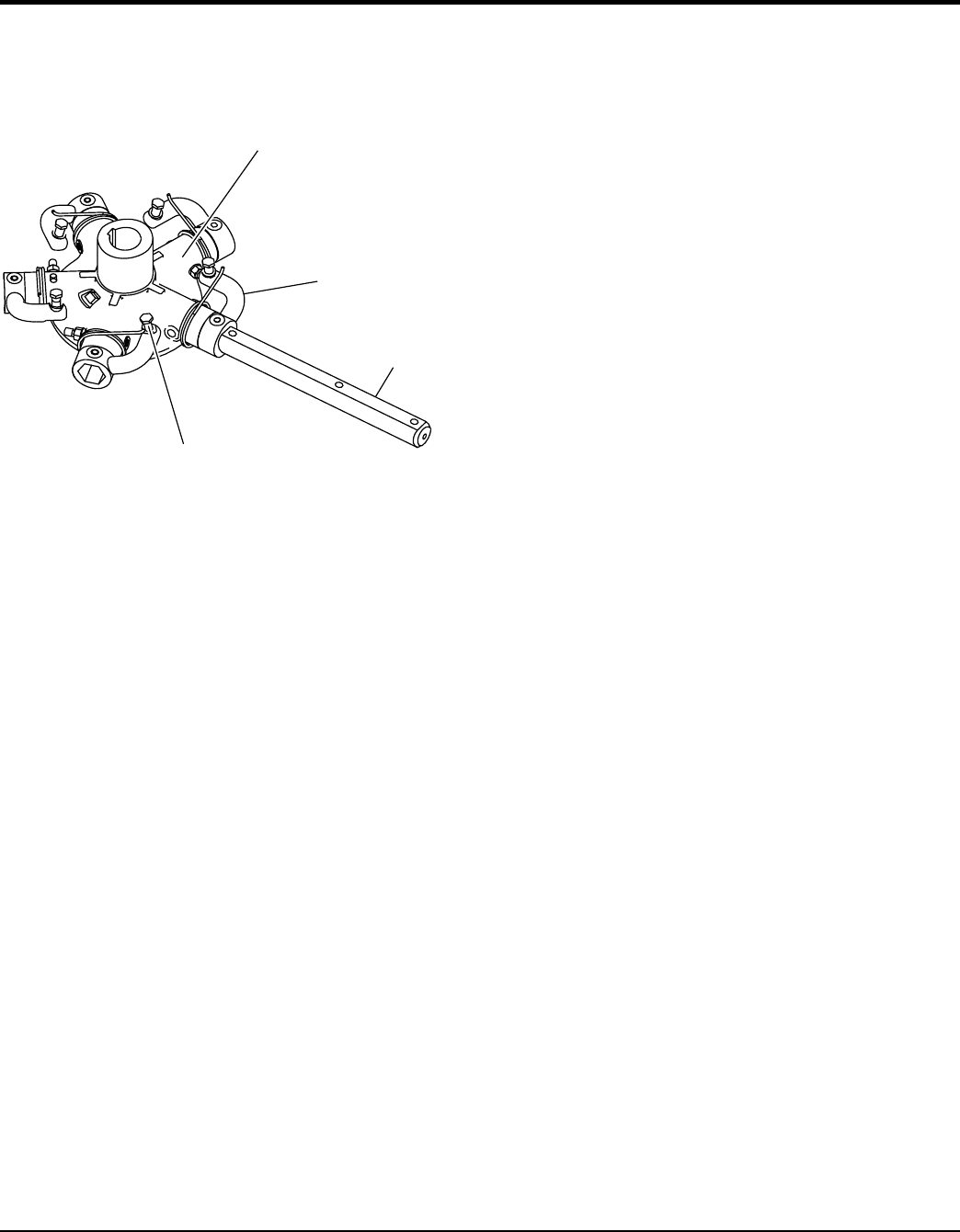

Figure 34. Blade Pitch Adjustment Bolt

The easiest and most consistent way to make adjustments

on the trowel arm fingers is to use the Trowel Arm Adjustment

Fixture (P/N 9177). It comes with all the hardware necessary

to properly accomplish this maintenance and instructions

on how to utilize this tool.

If a trowel arm adjustment fixture is not available and

immediate adjustment is necessary, temporary field

adjustment can be made if you can see or feel which blade

is pulling harder by adjusting the bolt that corresponds to

that blade.

A better way to determine which blades need adjustment

is to place the machine on a known FLAT surface (steel

metal plate) and pitch the blades as flat as possible. Look

at the adjustment bolts. They should all barely make contact

with the lower wear plate on the spider. If you can see that

one of them is not making contact, some adjustment will

be necessary.

Adjust the “high” bolts down to the level of the one that is not

touching, or adjust the “low” bolt up to the level of the higher

ones. If possible, adjust the low bolt up to the level of the

rest of the bolts. This is the fastest way, but may not always

work. Verify after adjustment the blades pitch correctly.

Blades that are incorrectly adjusted often will not be able to

pitch flat. This can occur if the adjusting bolts are raised too

Trowel

Arm

Trowel Lever

(Finger)

Spider Plate

Blade Pitch

Adjustment Bolt

high. Conversely, adjusting bolts that are too low will not allow

the blades to be pitched high enough for finishing operations.

If, after making Blade Pitch adjustments the machine is

still finishing poorly, blades, trowel arms, and trowel arm

bushings may be suspect and should be looked at for

adjustment, wear, or damage. See the following sections.

Changing Blades

It is recommended that ALL the blades on the entire

machine are changed at the same time. If only one or

some of the blades are changed, the machine will not

finish concrete consistently and the machine may wobble

or bounce.

1. Place the machine on a flat, level surface. Adjust

the blade pitch control to make the blades as flat as

possible. Note the blade orientation on the trowel arm.

This is important for ride-on trowels as the two sets

of blades counter-rotate. Lift the machine up, placing

blocks under the main guard ring to support it.

2. Remove the bolts and lock washers on the trowel arm,

and then remove the blade.

3. Scrape all concrete and debris from the trowel arm. This

is important to properly seat the new blade.

4. Install the new blade, maintaining the proper orientation

for direction of rotation.

5. Reinstall the bolts and lock washers.

6. Repeat steps 2-5 for all remaining blades.

Steering Adjustment

The steering assist adjustment should be performed only

by qualified service technicians. For HHXD5 steering

adjustment instructions, reference MQ Whiteman service

bulletin 200925.

Clean-Up

Never allow concrete to harden on the power trowel.

Immediately after use wash any concrete off the trowel

with water, be careful not to spray a hot engine or muffler.

An old paint brush or broom may help loosen any concrete

that has started to harden.