HHXD5 RIDE-ON TROWEL • OPERATION MANUAL — REV. #2 (05/04/12) — PAGE 37

MAINTENANCE

Blade Pitch

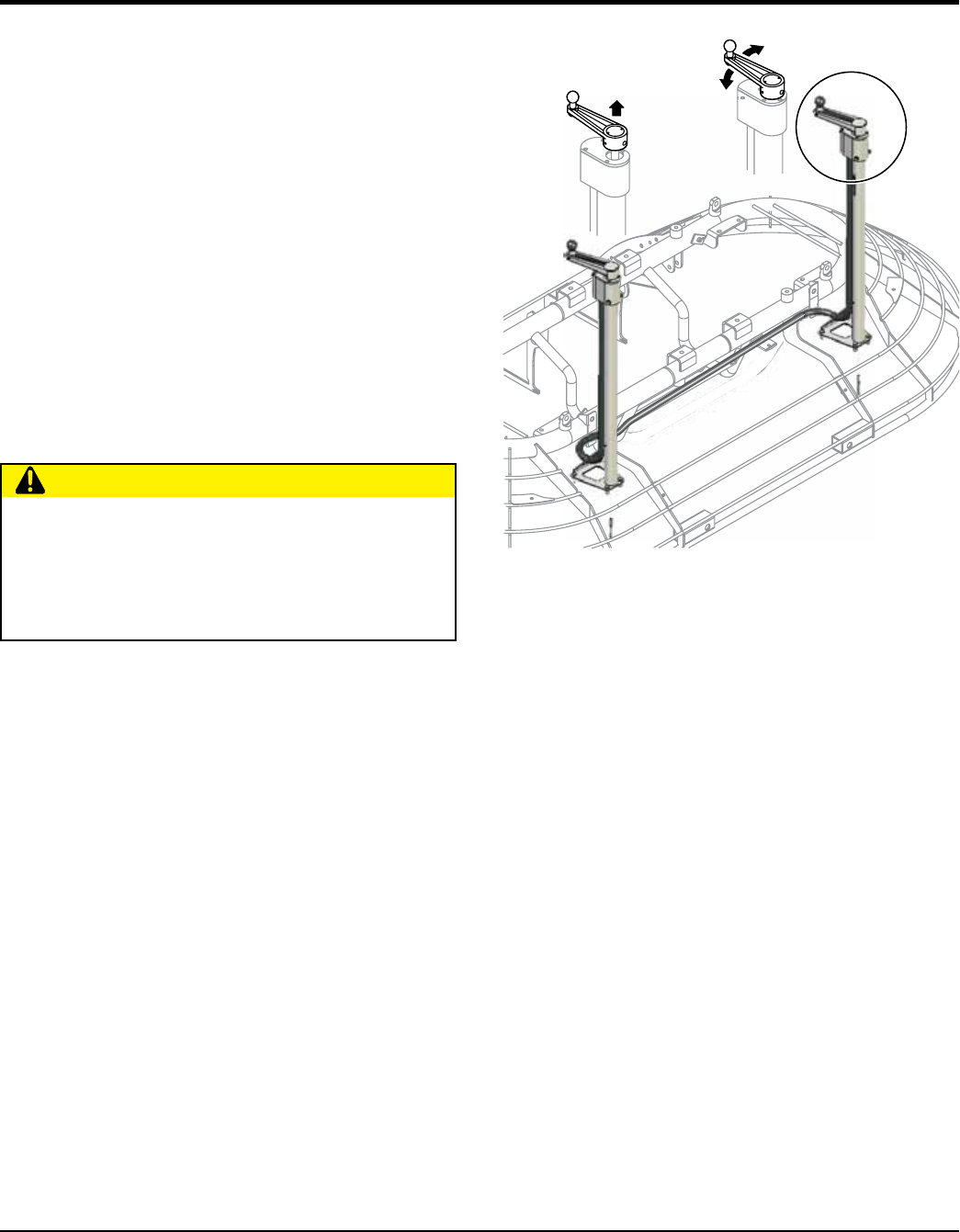

Matching Blade Pitch for Both Sets of Blades

Sometimes it may be necessary to match blade pitch

between the two sets of blades. There are some signs

that this may be necessary. For example, the differences

in pitch could cause a noticeable difference in finish quality

between the two sets of blades, or, the difference in blade

pitch could make the machine difficult to control. This is

due to the surface area in contact with the concrete (the

blade set with the greater contact area tends to stick to the

concrete more).

Single Pitch

On a Single Pitch trowel each spider assembly can be

pitched individually, forcing the operator to constantly make

adjustments on each pitch tower.

Twin Pitch

TM

Trowels equipped with Twin Pitch

TM

Controls may need

to have blade pitch between the two sets of blades

"syncronized". If the blades need to be syncronized this

is easily accomplished by performing the following. Refer

to Figure 33.

1. Lift the pitch adjustment handle on either side. Once

lifted, that side is now disconnected from the Twin

Pitch system.

2. Adjust to match the opposite side.

3. When adjusted, lower the handle to Twin Pitch

operating position.

CAUTION

When turning an adjustment handle, do not force it to

turn or damage to the cable may occur. If the cable

starts to noticeably twist this is a good indication that

one side is either all ready at full pitch or it is bound up

due to concrete, debris, or corrosion.

Figure 33. Pitch Towers

Blade Pitch Adjustment Procedure

Maintenance adjustment of blade pitch is made by adjusting

a bolt (Figure 34) on the arm of the trowel blade finger.

This bolt is the contact point of the trowel arm to the lower

wear plate on the thrust collar. The goal of adjustment is to

promote consistent blade pitch and finishing quality.

Look for the following indications if blades are wearing

unevenly. If so, adjustment may be necessary.

Is one blade is completely worn out while the others

look new?

Does the machine have a perceptible rolling or bouncing

motion when in use?

DISENGAGED

(ONE SIDE)

OPERATING POSITION