Filter Procedure for Model 690HD for use with fryers with drain valves.

CAUTION: Couple the hose. Pull hard on the hose to make sure the lever arms are locked.

Make sure hose nozzle is in the nozzle holder tube on the pump.

Filter oil at temperatures from 300°F to 350°F

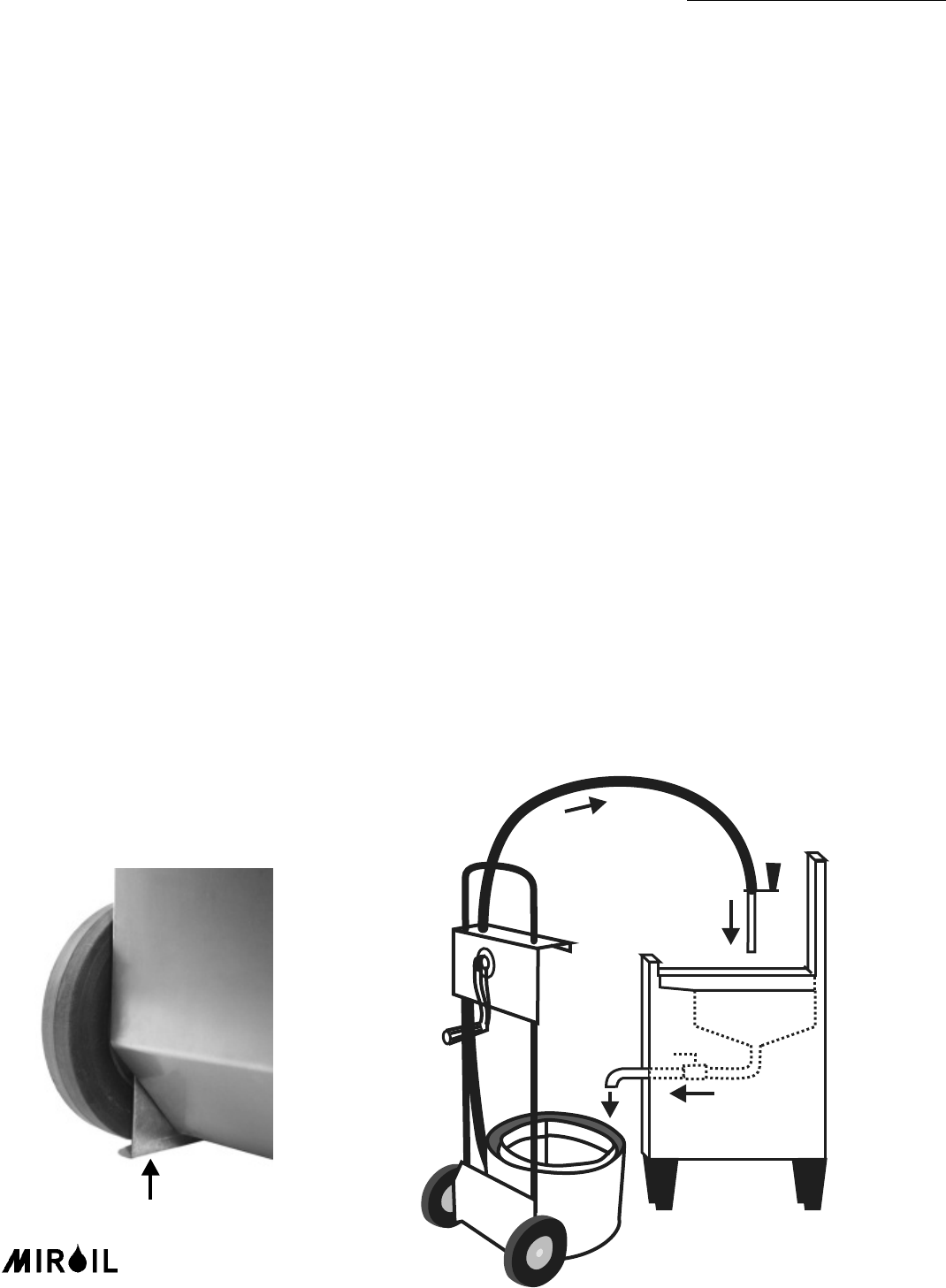

Step 1 - Swing wheel stabilizers into place as shown in diagram below (figure 1).

Step 2 - Place EZ Flow Model 905 Filter in the Basin (see diagram Figure 1).

Carefully open the fryer valve to drain oil into the filter basin through the filter bag.

Step 3 - Use a small amount of Frypowder on a damp cloth to clean "ring around the fryer" and any slight

residue of previous carbon formation on heating surfaces.

Aim hose nozzle carefully as you pump oil to flush crumb and powder residue from fryer.

Step 4 - Close the drain valve turn pump to return the oil back to the fryer

Step 5 - Discard heavy crumb load before filtering the next fryer. Use a bus tray or carton to allow the crumb

to cool because hot crumb will melt plastic garbage can liners.

Clean your filter under hot water spray. Store the filter in the filter basin to avoid accidental damage.

Do not wash the filter in a dishwasher or use soap. The least residue of soap is harmful to the oil.

If solid oil or shortening is used, before storing the filter machine, turn the pump handle

clockwise to empty the oil from the pump cavity.

Uncouple the hose and store it in a hanging position to prevent a fat plug from forming when it

collects and solidifies at a loop or bend of the hose.

More notes for great fried food:

1. Add Frypowder oil stabilizer to your oil after filtering and/or before each meal session. This will capture

oil breakdown substances as they form in the oil and prevent oil breakdown reactions.

2. Filter once a day when Frypowder oil stabilizer is used unless crumb load is extremely heavy.

3. Follow the filtering and freshening procedures described in your brochure for Frypowder oil stabilizer

and the New Frying Technology to choose an oil management program for your fry station.

For assistance call . . . . 1.800.523.9844

Division of Oil Process Systems Inc.

602-20 North Tacoma Street Allentown, Pennsylvania 18103

PHONE: 610 437-4618 FAX: 610 437-3377 E-mail: info@miroil.com Web: www.miroil.com

Wheel stabilizer in pumping position

Figure 1

Fryer

Return to main menu