11.12

Section 11

Reassembly

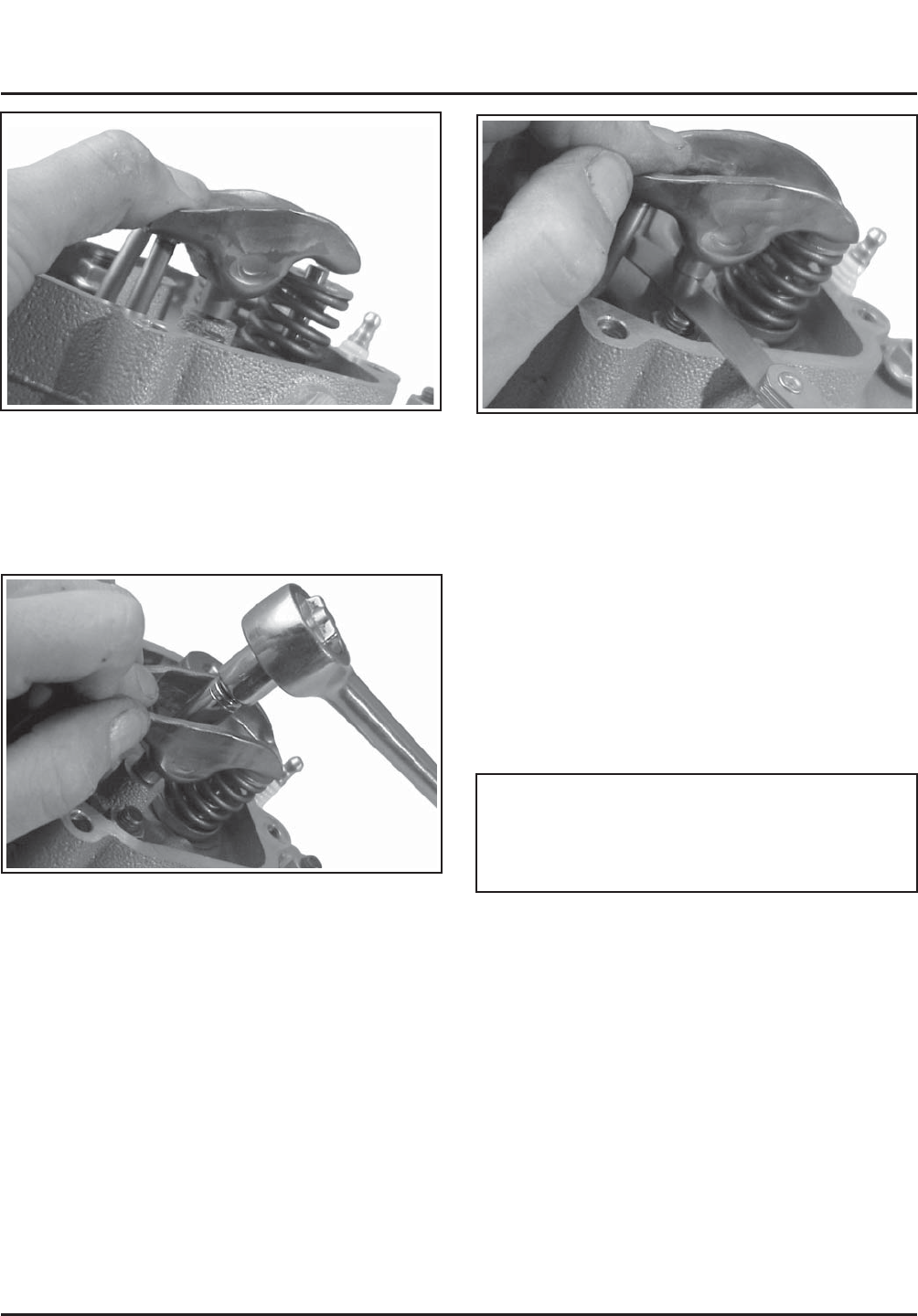

Figure 11-33. Depressing To Bottom Limit of Lifter

Plunger Travel.

10. With the lifter still compressed, slowly tighten

the rocker arm fastener (clockwise) until the free

end of the rocker arm just makes contact with the

end of the valve. See Figure 11-34.

Figure 11-35. Determining Clearance with Feeler

Gauge.

12. Add 0.004" to the dimension from step 11 and

record the total. This is the total shim thickness

required for proper valve lash. Refer to the

following table and determine which combination

of shims will get you closest to that total. If you

need additional shims, beside those taken out

during disassembly, refer to the parts manual and

order the shim kit. The kit contains a sufficient

assortment to cover all possible combinations on

one engine.

NOTE: Do not use the shim selection chart on

page 11.10 when using this procedure.

Available Shim Thickness & Identification:

.004 in. Shims contain a Blue Line

.008 in. Shims contain a Red Dot

.020 in. Shims contain a Black Dot

13. Remove the rocker arm assembly and place the

selected shims on the screw/stud, below the

pivot. Lightly lubricate all moving/contact surfaces

with engine oil.

14. Reassemble the rocker arm and pivot assembly

(with shims) to the head (see Figure 11-36) and

seat the push rod. Torque the fastener; 11.3 N·m

(100 in. lb.) for a hex. flange screw, or 17.3 N·m

(153 in. lb.) for a lock nut. See Figure 11-37.

Figure 11-34. Establishing ‘‘0’’ Lash/ ‘‘0’’ Preload.

11. While still maintaining pressure on rocker

arm/lifter, use a feeler gauge and determine the

existing clearance between the base of the pivot

and adjacent surface of the cylinder head. See

Figure 11-35. Record this dimension.

5/04