11

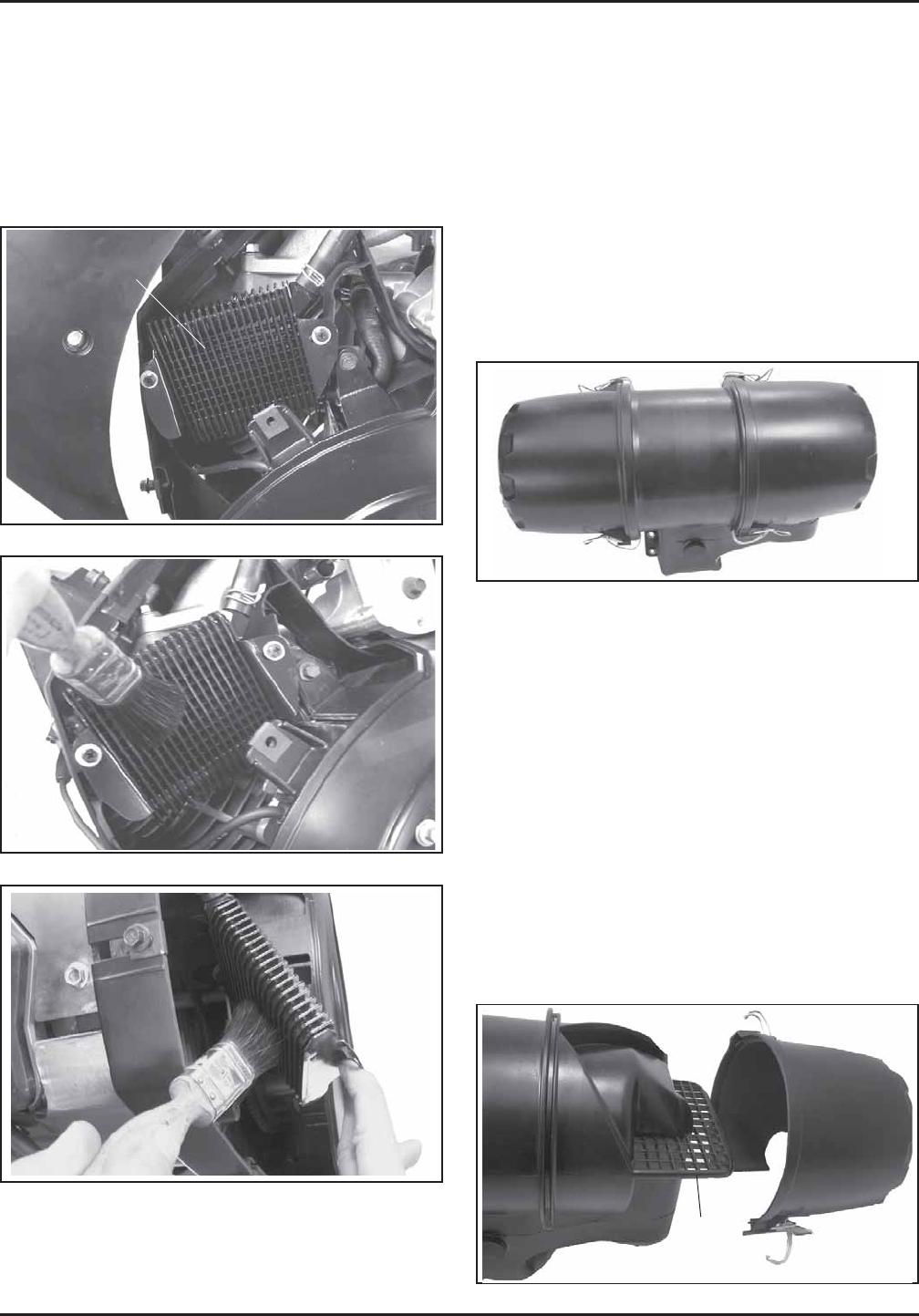

To access and service the oil cooler, remove the top

mounting screw and loosen the two side screws, then

lift off the No. 2 side cylinder shroud. If required,

remove the two screws holding the oil cooler to the

blower housing. Pull the cooler away from the blower

housing. Clean both sides of the cooler with a brush as

shown in Figures 17 and 18, or with compressed air.

After cleaning, reattach the oil cooler to the lower

blower housing with the two mounting screws.

Figure 17. Cleaning Top of Oil Cooler.

Figure 16. Oil Cooler.

Air Cleaners

These engines use a heavy-duty style air cleaner (see

Figure 19) or a flat air cleaner (see Figure 23). These

systems are CARB/EPA certified and the components

should not be altered or modified in any way.

NOTE: Lift or move this engine using the lifting

strap and lifting point shown in Figure 1.

DO NOT lift the engine by the air cleaner.

Heavy-Duty Air Cleaner

The heavy-duty air cleaner consists of a cylindrical

housing mounted to the carburetor and intake

manifold. The housing contains a paper element and

inner element, designed for longer service intervals.

Figure 19. Heavy-Duty Style Air Cleaner.

Service

Weekly and every 150 hours: Check filter minder (if

equipped), unhook the two retaining clips on each end

and remove the end caps. Perform inspection of the

paper element and inlet screen area.

Seasonally or every 300 hours of operation (more

often under extremely dusty or dirty conditions),

replace the paper element and check the inner

element. Follow these steps.

1. Unhook the two retaining clips on each end and

remove the end caps from the air cleaner housing.

2. Check and clean the screen area on the inlet side.

Pull the air cleaner paper element out of the

housing on opposite side. See Figures 20 and 21.

Figure 18. Cleaning Underside of Oil Cooler.

Figure 20. Accessing Inlet Screen.

Oil Cooler

Inlet

Screen