Maintenance/1000 hours/1 year

DPSG,CD03523,34 –19–13JUL99–2/2

RG7977 –UN–14NOV97

• Checking tensioner spring tension

A belt tension gauge will not give an accurate measure

of the belt tension when automatic spring tensioner is

used. Measure tensioner spring tension using a torque

wrench and procedure outlined below:

a. Release tension on belt using a breaker bar and

socket on tension arm. Remove belt from pulleys.

b. Release tension on tension arm and remove breaker

bar.

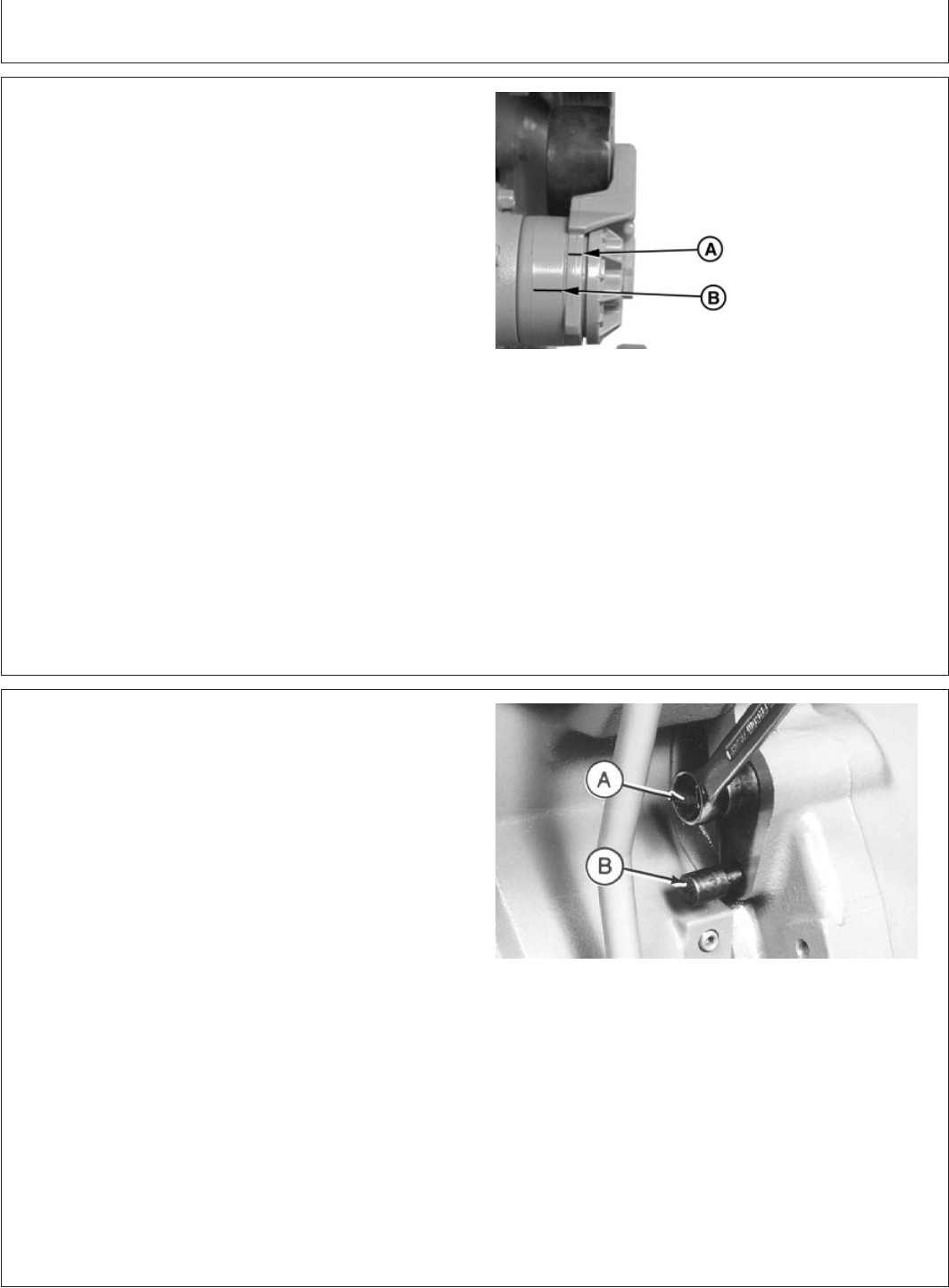

c. Put a mark (A) on swing arm of tensioner as shown.

d. Measure 21 mm (0.83 in.) from (A) and put a mark

(B) on tensioner mounting base.

e. Rotate the swing arm using a torque wrench until

marks (A) and (B) are aligned.

f. Record torque wrench measurement and compare

with specification below. Replace tensioner assembly

as required.

Spring—Specification

Force 18—22 N•m (13—16 lb-ft).................................................................

DPSG,CD03523,35 –19–13JUL99–1/4

CHECK AND ADJUST ENGINE VALVE

CLEARANCE (300-SERIES ENGINES)

CD30544 –UN–19MAY98

NOTE: Valve clearance must be adjusted after the first

500 hours of operation, then every 1000 hours

thereafter.

Adjust engine valve clearance as follows or have your

authorized servicing dealer or engine distributor adjust the

engine valve clearance.

1. Remove rocker arm cover and crankcase vent tube.

2. Using JDE83 or JDG820 Flywheel Turning Tool (A),

rotate engine flywheel in running direction (clockwise

viewed from water pump) until No.1 piston (front) has

reached top dead center (TDC) on compression stroke.

Insert timing pin JDE81-4 (B) into flywheel bore.

35-3

112699

PN=54

Continued on next page