10

Engine Oil

Checking, Adding and Changing Oil

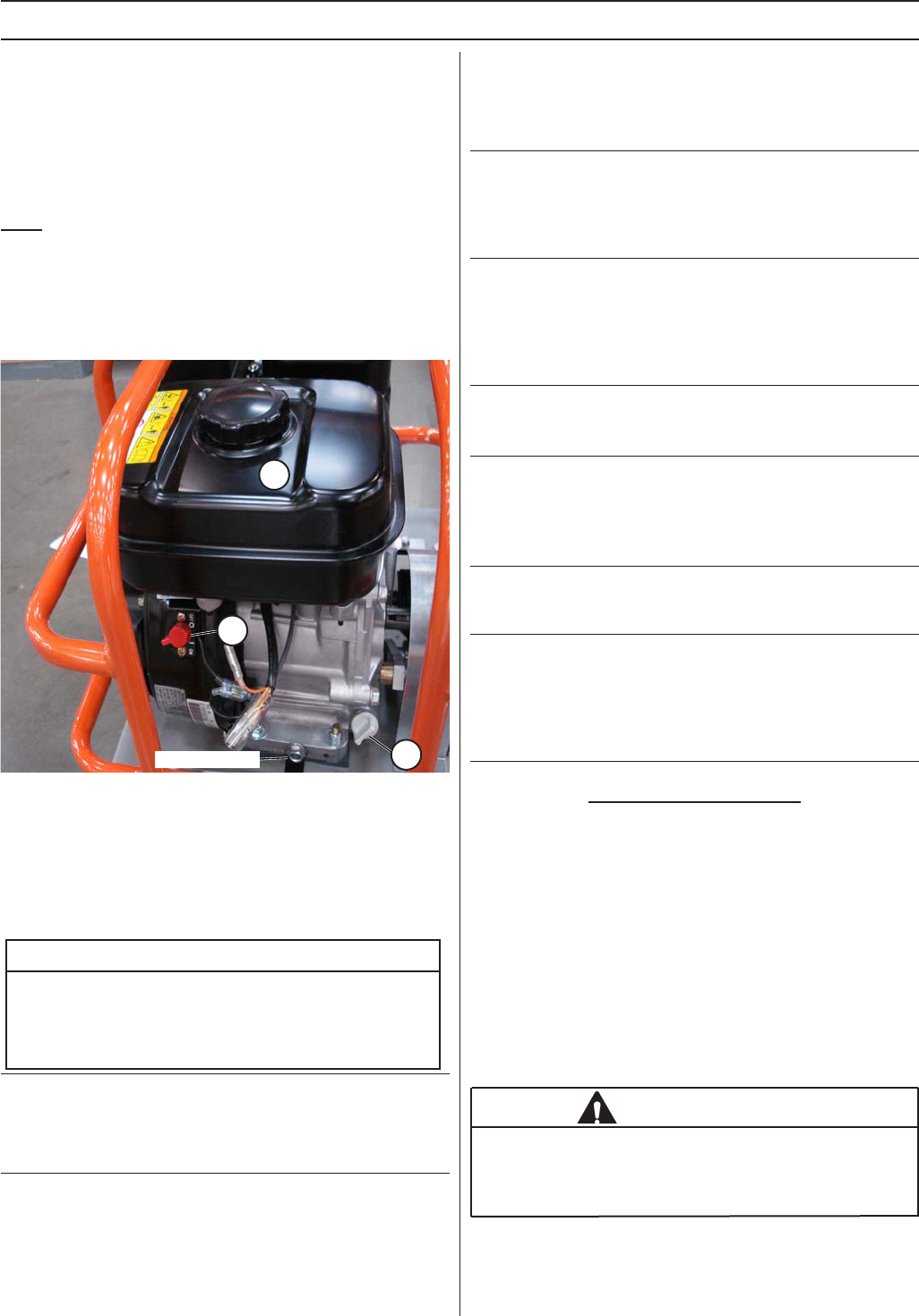

Check the engine oil level (A) daily with saw fully lowered and

the engine level. See the enclosed Robin manual for more

details.

Use SAE 10W-30 viscosity detergent automotive type with API

service class SE or higher grade oil.

Note: Engine holds approximately 0.6 quart (0.6 liter) when

changing oil and oil lter.

Changing the Oil

Change oil after the rst 5 to 8 hours of use.

Thereafter every 50 hours.

MAINTENANCE

Guards

Check all guards for damage and proper function daily espe-

cially the blade block. Blade block and cover should be secure

to the saw and not damaged. Lexan side covers on the blade

block should move freely up and down.

The oil drain plug is located at the bottom of the engine block.

Place a pan under the drain and remove the plug. Drain the oil

and replace the plug. Using a long neck funnel, ll the engine

with 0.6 quarts (0.6 liters) of oil. When full, the oil level should

be at the high level mark on the dipstick (A) or to the top of the

threads on the engine ll hole. The engine is equipped with an

oil alert system that will stop the engine if the oil level is low.

A

Oil drain plug

NOTICE

Used oil is a hazardous waste product. Dispose of

used oil properly. Do not discard with household

waste. Check with your local authorities, service

center, or dealer for safe disposal/recycling facility.

AIR FILTER

The air cleaner element should be replaced every 50 hours.

Refer to the supplied engine manual and the “Cyclone Dual-

Filter-Element Type” for additional information.

ADDITIONAL ENGINE INFORMATION

Please see the Robin Operator’s Manual for additional infor-

mation about servicing the engine.

The manual also has specic information about specications,

tune-up parts, engine warranty, emission compliance, etc.

Diamond blade

Inspect diamond blades daily for damage, cracks, secure t

to the arbor, loss of segments, warping or overheating. If any

blade shows any of these problems, discard the blade and

never use.

Skid plate

Inspect the skid plate daily for damage, excessive wear in the

blade slot, burrs on the concrete surface side, twisting and

free movement up and down when installed in the blade block.

Replace the skid plate with each new diamond blade. Never

reuse skid plates or spalling and ravelling may results.

Saw controls

Inspect all controls for proper function daily. Check the engine

on/off switch (J) for proper operation.

J

Belts

Inspect the blade drive belt for cracks or signs of wear. The

belt tension is controlled by belt tensioner and does not require

adjustment. Inspect the belt tensioner for free movement up

and down. Insure the belt tensioner bearings roll freely.

Blade shaft bearings

Lubricate the blade shaft bearings with 3 pumps of Lithium 12

based grease every 50 hours.

MAINTENANCE SCHEDULE

Check guarding, diamond blade, Daily

skid plate, lexan covers, controls and oil levels.

Clean blade block assembly and saw. Daily

Replace air cleaner. Every 50 hours

Replace engine oil. Every 50 hours

Grease blade shaft bearings. Every 50 hours

Check blade drive belt. Every 50 hours

Cleaning

Clean the blade block of any excess concrete build up after

each use. Keep the handle bars and controls clean and dry.

Immediately clean any spilled fuel (H) from the saw. Keep all

openings and slot on the saw clean open so air ows freely

through the engine compartment to insure proper cooling.

H

WARNING

Do not modify the saw! Use only Husqvarna Construc-

tion Products replacement parts. Use of unauthorized

parts may create a danger or damage the engine.