63-2493—1

4

ML6275 SPRING RETURN DIRECT COUPLED ROTARY ACTUATOR

INSTALLATION

When Installing this Product…

ᕡ Read instructions carefully. Failure to follow them could

damage the product or cause a hazardous condition.

ᕢ Check ratings and description given in the specifications

to make sure the product is suitable for your application.

ᕣ Installer must be a trained, experienced service

technician.

ᕤ After installation is complete, check out product operation

as provided in these instructions.

CAUTION

1. Disconnect power before installation to prevent

electrical shock or equipment damage.

2. Never turn motor output hub by hand or wrench.

3. Do not install actuator in areas with acid fumes or

other deteriorating vapors that might attack the

metal parts of the actuator.

4. Do not install actuator in areas with escaping gas

or other explosive vapors that could be ignited by

a spark from the actuator or attached accessories.

Location

Install the actuator in any location free from acid fumes or

other deteriorating vapors that might attack the metal parts of

the actuator. Make sure the location is not subject to

escaping gas or other explosive vapors that could

accidentally be ignited by a spark from the actuator or its

attached parts.

Install the actuator in a location that allows enough clearance

for mounting accessories and for servicing.

Mounting

The ML6275 Direct Coupled Actuator is designed to operate

a damper by driving the damper shaft either cw or

ccw depending on damper design. All actuators are

shipped in the fully closed position.

The ML6275 Direct Coupled Actuator is designed for single-

point mounting when using an adapter bracket. Single-point

mounting is typically used when the actuator is mounted on

the damper frame.

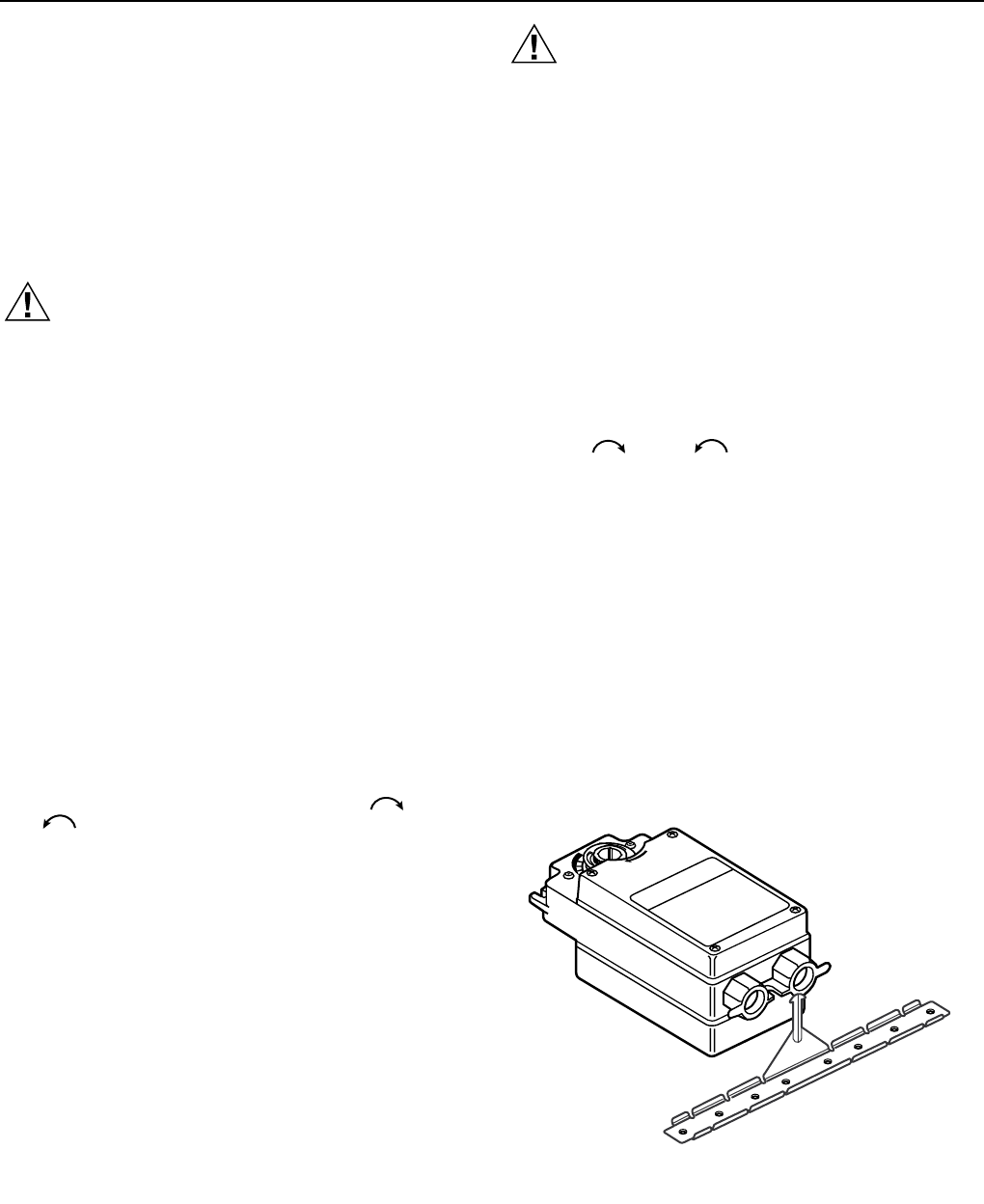

A mounting bracket (see Fig. 1) is provided with some models

to aid in installing the actuator. The bracket can be bent to any

shape to support the actuator at the correct height.

The ML6275 Direct Coupled Actuator can also be three-point

mounted using the two front gear housing slots and the

adapter bracket. Two screws are secured through the two

front gear housing slots and the adapter bracket positioned to

secure the rear of the actuator. Three point mounting is used

for foot mounting the actuator or internally mounting the

actuator in the duct when direct shaft coupling is not possible.

6

0

3

0

9

0

M9386

Fig. 2. Installing mounting bracket on ML6275 Direct

Coupled Actuator.

CAUTION

Do not use the actuator as a shaft bearing. The

actuator must be used only to supply rotational torque.

To prevent damage to the actuator, avoid any side

loads to the actuator output coupling bearings.

Preparation

Before installing the ML6275 on the damper shaft, determine

the opening direction of the damper shaft to determine the

correct spring return rotation and correctly connect the wiring.

The ML6275 can be mounted to provide clockwise or

counterclockwise spring return. Reverse the actuator if

necessary to provide the desired spring action.

Installation

Installing the Actuator and Mounting Bracket

(Single Point Mounting)

When the direction of the damper shaft rotation is determined

(either cw or ccw ), proceed as follows:

ᕡ Place the ML6275 Direct Coupled Actuator over the

damper shaft.

ᕢ Position the actuator for best access to the actuator

damper shaft locking screw.

ᕣ Install the mounting bracket (see Fig. 2) and adjust it to

support the actuator at the correct height. Mark the

screw holes for installing the mounting bracket on the

damper housing.

ᕤ Remove the mounting bracket and actuator.

ᕥ Drill or center punch the starting holes for the mounting

bracket screws (or use no. 10 self-tapping sheet metal

screws).

ᕦ Place the actuator and mounting bracket back into

position over the damper shaft and install the mounting

bracket screws.

ᕧ Tighten the two 8 mm by 12 mm long set screws firmly

against the damper shaft (maximum tightening torque is

100 lb-in.).