63-2483—2 8

ML6185

INSTALLATION

Fig. 6—ML6185 Actuator standard electrical

connection.

.500

.500

30

30

60

60

90

M7231

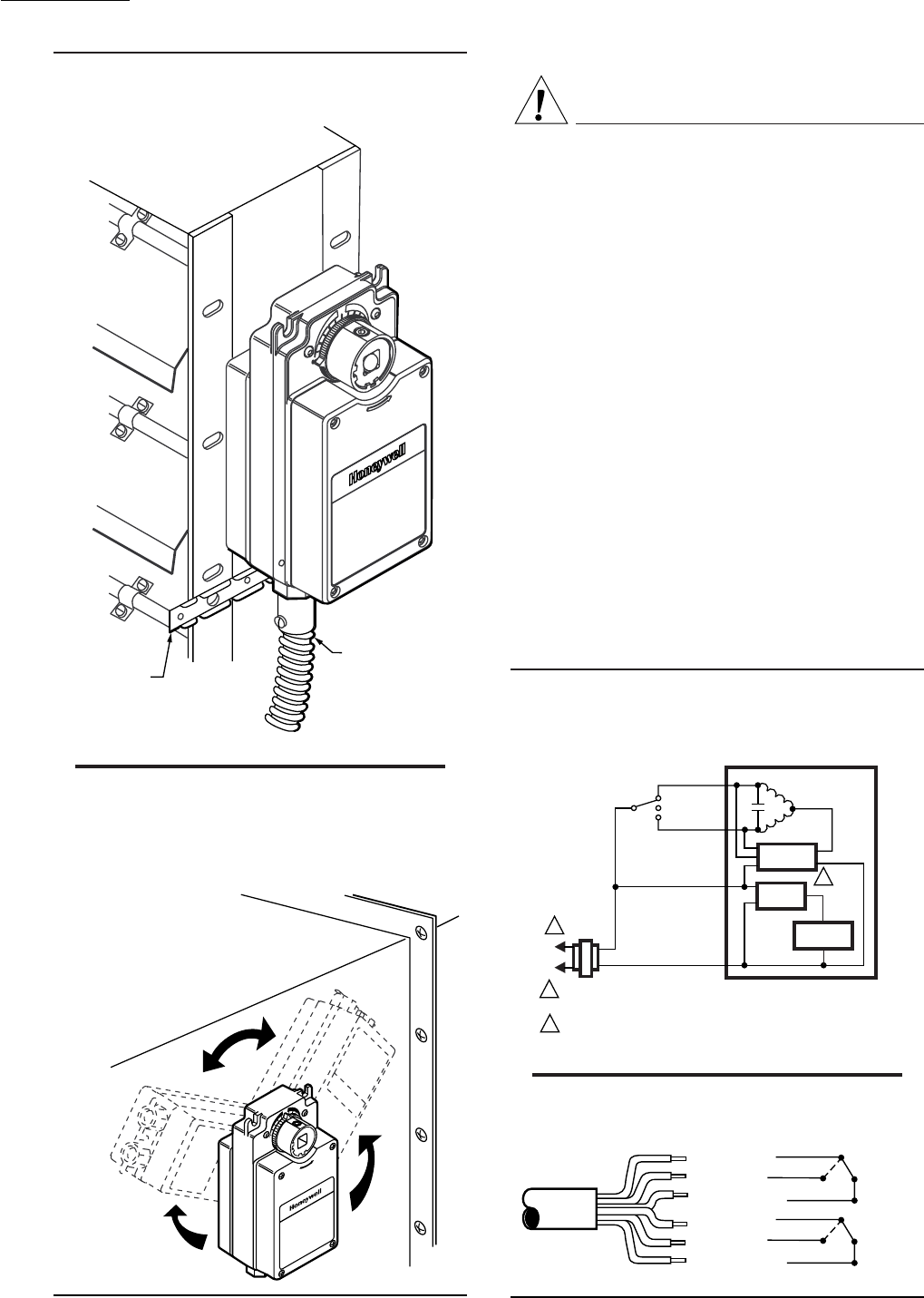

MOUNTING

BRACKET

TO JUNCTION

BOX (UP TO

3 FT. AWAY)

Fig. 7—ML6185 Actuator can be mounted in

any position. (NOTE: NEMA rating applies only

with damper shaft in the horizontal position.)

WIRING

CAUTION

Disconnect power supply before wiring to prevent

electrical shock or equipment damage.

All wiring must comply with local electrical codes,

ordinances and regulations. The ML6185 is designed for

use with a Class 2 power supply. Voltage and frequency of

the transformer used must correspond with the characteris-

tics of the motor and those of the power supply. See Fig. 8

for a typical wiring connection.

The ML6185 has an aluminum die cast housing with

two integral cast bosses on the end of the device, tapped for

1/2 in. conduit fittings. Some models are shipped with a

water seal in the conduit opening. When conduit is needed,

remove the seal before routing the cable.

ML6185 models with Factory-mounted Auxiliary

Switches (See Fig. 9)

ML6185C,F models have two nonadjustable line volt-

age rated spdt auxiliary switches with switches factory set

to make common to normally open at 12° and 82° rotation

from the counterclockwise stop. See Fig. 9.

IMPORTANT: Actuators driving in parallel may not be

synchronized with each other. In normal operation, if

all actuators are driven to the fully open or fully closed

position, the actuators will again be synchronized.

Fig. 8—ML6185 typical wiring diagram.

M9384

30

0

60

500

500

90

60

30

L1

(HOT)

L2

1

1

2

2

MOTOR

OPTIONAL

TIME OUT

POWER

SUPPLY

SPRING

CONTROL

24 VAC

OPEN

BLUE

CLOSE

YELLOW

24 HOT

RED

24 GND

BLACK

ML6185

M7224

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

TIME OUT FUNCTION AVAILABLE WITH ML6185D,F MODELS.

WHITE/RED

WHITE/BLUE

WHITE/YELLOW

BLACK/RED

BLACK/BLUE

BLACK/YELLOW

AUX. SWITCHES

3A 120 VAC

12°

82°

M7227A

Fig. 9—ML6185C,F wiring for auxiliary

switches.