Sensing and Control, 11 West Spring Street, Freeport, Illinois 61032

Printed in U.S.A. © Copyright 2000—Honeywell

Herculine

11280S

Smart Actuator

61-86-03-13

9/01

Page 1 of 14

Specification

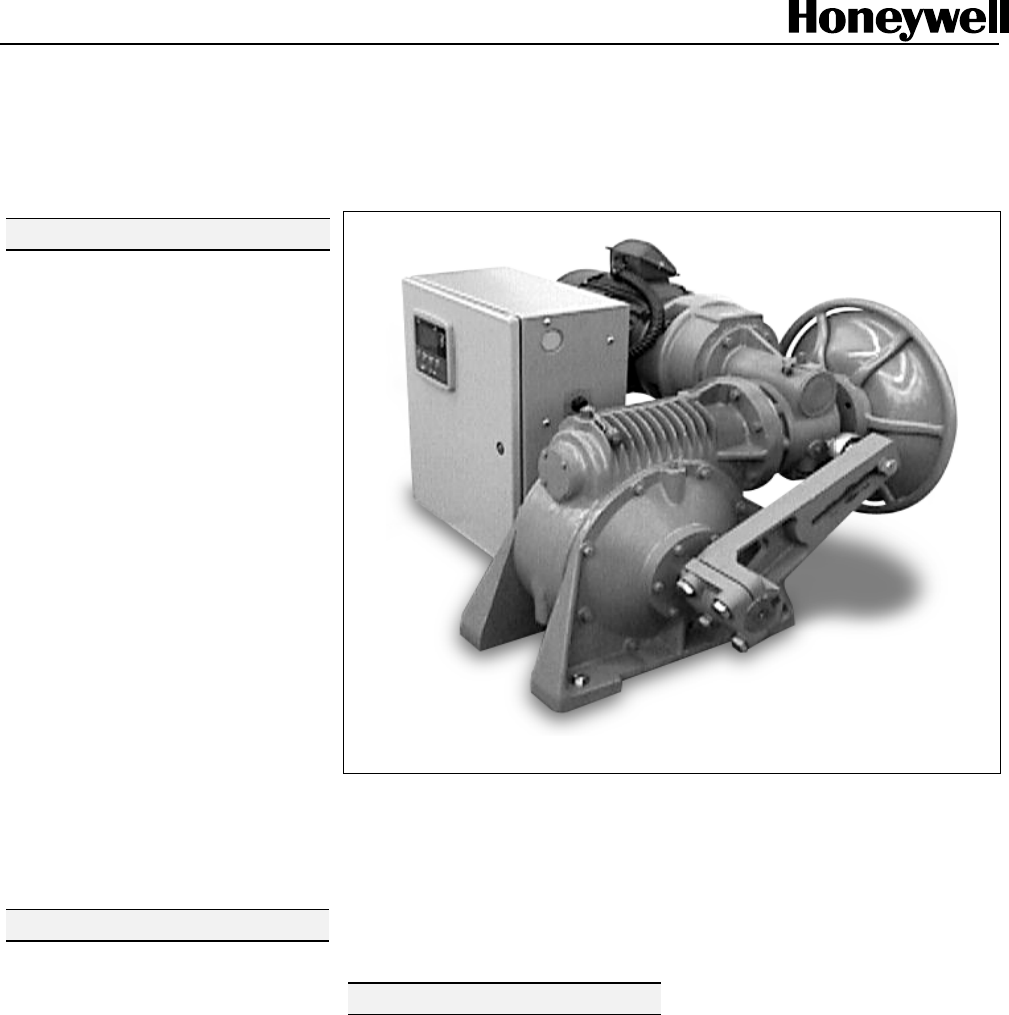

Figure 1 Herculine 11280S Smart Actuator

Overview

Honeywell’s HercuLine

11280S Smart

actuators incorporate all of the high

quality and reliable features of the

traditional HercuLine

actuators plus

the added benefits of a microprocessor-

based Enhanced Electronics Unit (EEU).

These additional benefits provide:

•

•

•

Faster set-up and commissioning

Network capability

Health parameter monitoring for

proactive maintenance planning.

HercuLine 11280S Smart actuators

enable operation at maximum process

efficiency, minimal downtime, and

access to all actuator parameters for

real-time business decisions.

Honeywell’s 11280S actuators are

industrial rated and engineered for very

precise positioning of dampers and

valves. The HercuLine 11280S

performs especially well in extremely

demanding environments requiring

continuous duty, high reliability, and low

maintenance. Typical applications are

ID/FD fan dampers, furnace pressure

dampers, coal mill dampers, burner tilts

and more.

Actuator Operation

Microprocessor-based electronics

continually monitor the performance,

health, and position of the actuator for

repeatable positioning and response to

demand signal.

A double reduction worm gear set

combines with a variable speed motor

controller (inverter) that is continuous

duty rated for accurate and repeatable

positioning of final control elements.

The worm gear set combination also

functions as a brake, capable of holding

greater than two times the output torque

in a back-driving condition.

Control options are available to

interface with a modulating 4-20 mA

input signal and 4-20 mA customer

feedback or remote setpoint through

Modbus. Internal balance, customer

feedback and patented slidewire

emulation is provided by a non-

contacting position sensor.

Features

Performance

• Accurate Positioning –

Motor/gear train provides accurate

positioning with almost

instantaneous start/stop

characteristics.

• Non-Contact Position Sensing –

Non-contacting sensing lowers

maintenance costs and improves

performance.

• Duty Cycle – Continuous duty

rated motor.

• Full Travel Speed – Full stroke

travel speeds as fast as 10

seconds.

• Torque – High torque capability in

small package (425 – 5,500 lb-ft).

• High Accuracy – Typically 0.25 %

of 90° span.

• High Repeatability - Typically

0.2 % of 90° span.

• Characterization – Linear, square

root or programmable user-

configured 21-point

characterization allows tailoring of

control for specific applications.

• Input Filter Setting – Four

programmable combinations of

input filter settings are provided to

accommodate various customers

needs. The combinations are

none, spike, low pass, or spike +

low pass filter.

• Deadband – Deadband is

programmable between 0.2 % to

5 % of 90° span.