used to check bore wear and taper against

the Specifications, but this is a pointless

operation if the engine is obviously in need of

reboring due to excessive oil consumption.

5 Your engine reconditioner will be able to

re-bore the block for you and supply the

correct oversize pistons to give the correct

running clearance.

6 If the engine has reached the limit for

reboring then cylinder liners can be fitted, but

here again this is a job for your engine

reconditioner.

7 To rectify minor bore wear it is possible to

fit proprietary oil control rings. A good way to

test the condition of the engine is to have it at

normal operating temperature with the spark

plugs removed. Screw a compression gauge

(available from most motor accessory stores)

into the first plug hole. Hold the accelerator

fully depressed and crank the engine on the

starter motor for several revolutions. Record

the reading. Zero the tester and check the

remaining cylinders in the same way. All four

compression figures should be approximately

equal and within the tolerance given in the

Specifications. If they are all low, suspect

piston ring or cylinder bore wear. If only one

reading is down, suspect a valve not seating.

Crankshaft and bearings

8 Examine the crankpin and main journal

surfaces for signs of scoring or scratches.

Check the ovality of the crankpins at different

positions with a micrometer. If more than

0.001 inch (0.025 mm) out of round, the

crankpins will have to be reground. They will

also have to be reground if there are any

scores or scratches present. Also check the

journals in the same fashion.

9 Wear in a crankshaft can be detected while

the engine is running. Big-end bearing and

crankpin wear is indicated by distinct metallic

knocking, particularly noticeable when the

engine is pulling from low engine speeds. Low

oil pressure will also occur.

10 Main bearing and journal wear is indicated

by engine rumble increasing in severity as the

engine speed increases. Low oil pressure will

again be an associated condition.

11 Crankshaft grinding should be carried out

by specialist engine reconditioners who will

supply the matching undersize bearing shells

to give the required running clearance.

12 Inspect the connecting rod big-end and

main bearing shells for signs of general wear,

scoring, pitting and scratching. The bearings

should be matt grey in colour.

13 If a copper colour is evident, then the

bearings are badly worn and the surface

material has worn away to expose the underlay.

Renew the bearings as a complete set.

14 At the time of major overhaul it is

worthwhile renewing the bearing shells as a

matter of routine even if they appear to be in

reasonably good condition.

15 Bearing shells can be identified by the

marking on the back of the shell. Standard

sized shells are usually marked STD or 0.00.

Undersized shells are marked with the

undersize such as 0.25 mm.

Connecting rods

16 Check the alignment of the connecting

rods visually. If you suspect distortion, have

them checked by your dealer or engine

reconditioner on the special jig which he will

have.

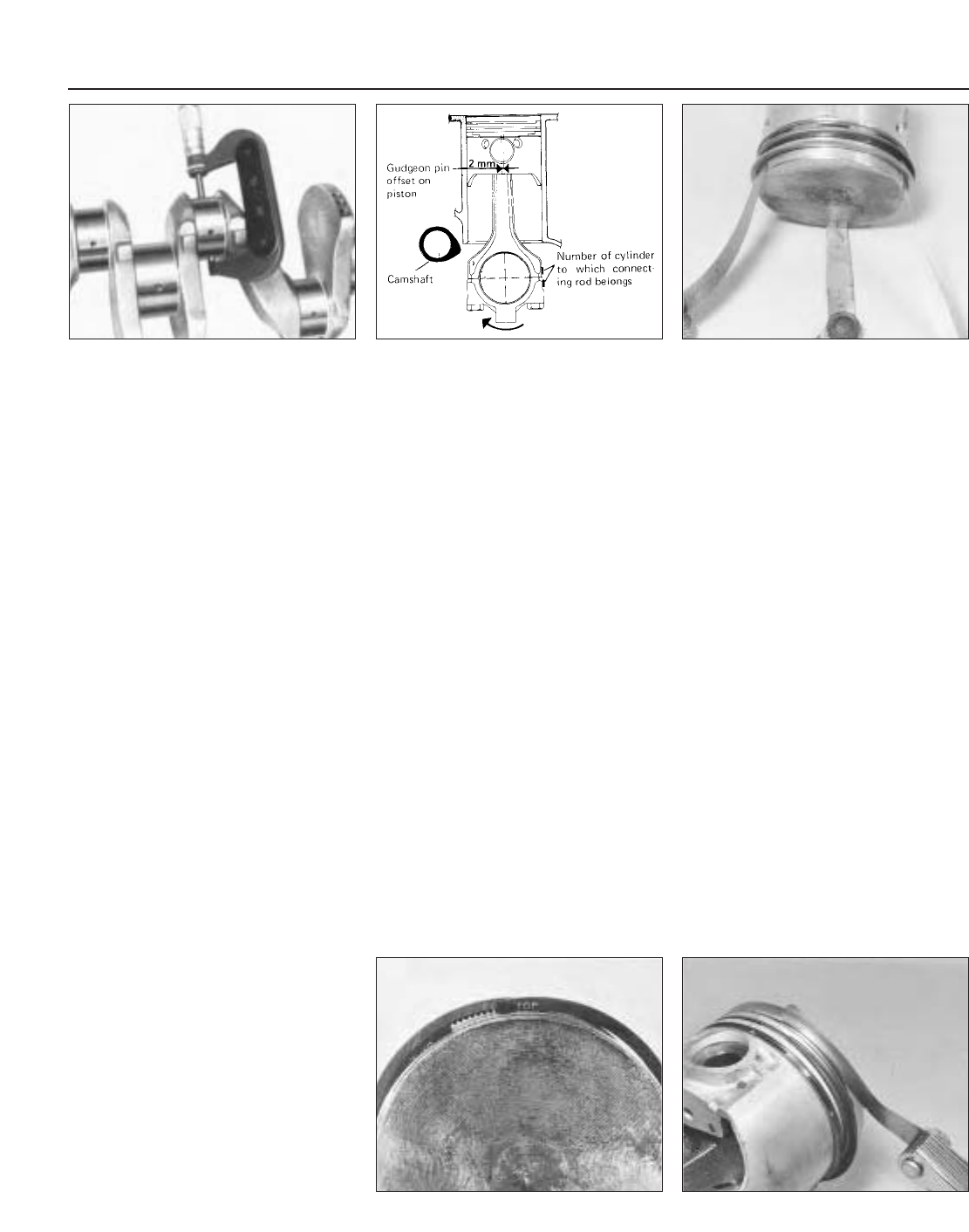

17 The gudgeon pin is an interference fit in

the connecting rod small-end and removal or

refitting and changing a piston is a job best

left to your dealer or engine reconditioner due

to the need for a press and jig and careful

heating of the connecting rod.

Pistons and piston rings

18 If the cylinders have been rebored, then

the reconditioner will supply the oversize

pistons and rings and the gudgeon pins. Give

the job of fitting the new pistons to the

connecting rods to him.

19 If the original piston rings or just new rings

are to be fitted to the original pistons, use

great care to remove and fit the rings as they

are easily broken if expanded too much.

Always remove and fit rings from the crown

end.

20 If three old feeler blades are slid behind

the piston rings and located at equidistant

points, the rings may be removed or fitted

without their dropping into the wrong grooves

and will reduce the chance of breakage

(photo).

21 If the original pistons are being refitted,

make sure that the ring grooves and their oil

return holes are cleaned out and freed from

carbon. A piece of piston ring is a useful tool

for this purpose.

22 The three pistons rings are as follows:

Top - Thinner compression marked TOP

Second - Thicker compression, step at base

Bottom - Oil control (photo)

23 If proprietary wear control rings are to be

fitted to overcome bore wear, fit them strictly

in accordance with the manufacturer’s

instructions.

24 Always check the piston ring groove

1•18 903 cc engine

18.24A Checking piston ring groove

clearance

18.22 Piston ring marking

18.20 Using feeler blades to fit piston ringsFig. 1.26 Piston/connecting rod

relationship (Sec 18)

Fig. 1.25 Checking a crankpin (Sec 18)