Maintenance

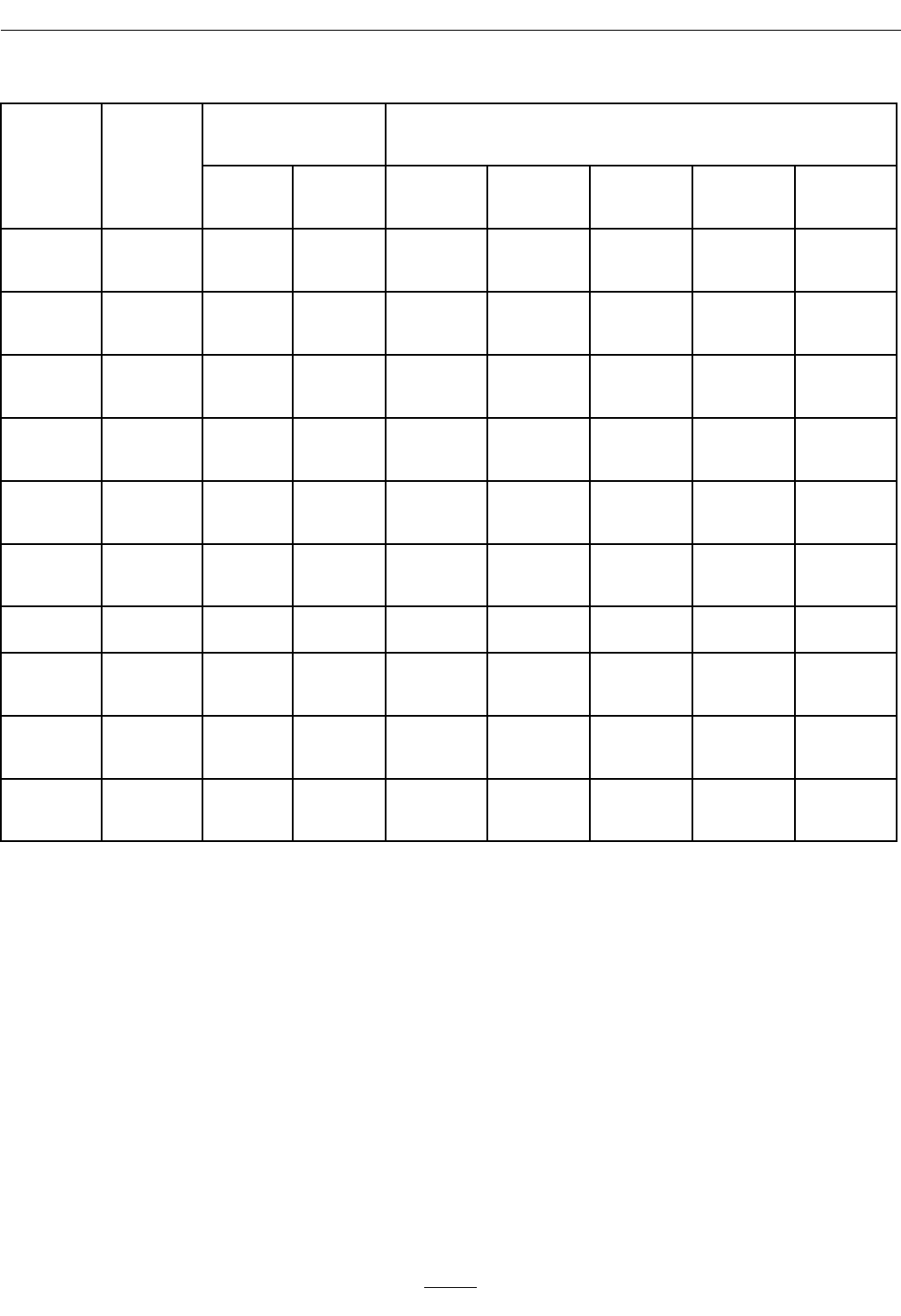

Cutting Height Adjustment Table (1 inch to 4 1/4 inches (2.5 cm-10.8 cm)) (cont'd.)

Number Of Spacers

Below Caster

Support Hub

Number of 1/4 inch (.64 cm) Blade Spacers Below Spindle

Cutting

Height

Range

Axle

Position

(Figure 11)

1/2

inch

(1.2 cm)

3/16

inch

(.48 cm)

4

3 2

1 0

2 1/8–

3 1/8 inches

(5.4–7.9 cm) C 2 0

2 1/8 inch

(5.4 cm)

2 3/8 inch

(6.0 cm)

2 5/8 inch

(6.7 cm)

2 7/8 inch

(7.3 cm)

3 1/8 inch

(7.9 cm)

2 1/4–

3 1/4 inches

(5.7–8.3 cm) C 2 1

2 1/4 inch

(5.7 cm)

2 1/2 inch

(6.4 cm)

2 3/4 inch

(7.0 cm)

3 inch

(7.6 cm)

3 1/4 inch

(8.3 cm)

2 1/2–

3 1/2 inches

(6.4–8.9 cm) C 3 0

2 1/2 inch

(6.4 cm)

2 3/4 inch

(7.0 cm)

3 inch

(7.6 cm)

3 1/4 inch

(8.3 cm)

3 1/2 inch

(8.9 cm)

2 3/8–

3 3/8 inches

(6.0–8.6 cm) D 2 1

2 3/8 inch

(6.0 cm)

2 5/8 inch

(6.7 cm)

2 7/8 inch

(7.3 cm)

3 1/8 inch

(7.9 cm)

3 3/8 inch

(8.6 cm)

2 1/2–

3 1/2 inches

(6.4–8.9 cm) D 3 0

2 1/2 inch

(6.4 cm)

2 3/4 inch

(7.0 cm)

3 inch

(7.6 cm)

3 1/4 inch

(8.3 cm)

3 1/2 inch

(8.9 cm)

2 3/4–

3 3/4 inches

(7.0–9.5 cm) D 3 1

2 3/4 inch

(7.0 cm)

3 inch

(7.6 cm)

3 1/4 inch

(8.3 cm)

3 1/2 inch

(8.9 cm)

3 3/4 inch

(9.5 cm)

3–4 inches

(7.6–10.1 cm) D 4 0

3 inch

(7.6 cm)

3 1/4 inch

(8.3 cm)

3 1/2 inch

(8.9 cm)

3 3/4 inch

(9.5 cm)

4 inch

(10.1 cm)

2 7/8–

3 7/8 inches

(7.3–9.8 cm) E 3 1

2 7/8 inch

(7.3 cm)

3 1/8 inch

(7.9 cm)

3 3/8 inch

(8.6 cm)

3 5/8 inch

(9.2 cm)

3 7/8 inch

(9.8 cm)

3 1/8–

4 1/8 inches

(7.9–10.5 cm) E 4 0

3 1/8 inch

(7.9 cm)

3 3/8 inch

(8.6 cm)

3 5/8 inch

(9.2 cm)

3 7/8 inch

(9.8 cm)

4 1/8 inch

(10.5 cm)

3 1/4–

4 1/4 inches

(8.3–10.8 cm) E 4 1

3 1/4 inch

(8.3 cm)

3 1/2 inch

(8.9 cm)

3 3/4 inch

(9.5 cm)

4 inch

(10.1 cm)

4 1/4 inch

(10.8 cm)

Important: Always adjust the Number of Spacers below Caster Hub to correspond to the Axle

Position as shown in table to obtain proper “rake” (blades should always be level to the ground

or tipped slightly down at the front).

Adjusting the Axle Position

Desired cutting height range can be obtained by

adjusting the rear axle and placing caster spacers

above or below the caster arm (see Figure 11 and

Figure 12 along with the Cutting Height Adjustment

Chart).

To adjust rear axle:

1. Stop the machine and move the drive levers to

the neutral lock position.

2. Disengage the PTO.

3. Raise the rear of the machine up onto jack stands

and remove the drive wheels.

4. Loosen but do not remove the top two bolts

on each hydraulic motor mounting bracket (see

Figure 11).

5. Remove the bottom sets of hardware for each

bracket.

6. Reposition the mounting bracket to the desired

height and reinstall the bottom hardware.

7. Tighten all hardware and remount drive wheels.

29