©2005 Edelbrock Corporation

Brochure #63-0434

Catalog #71884

Rev. 12/05 - DC/mcPage 3 of 4

9. Find a secure location to mount the Performer

Nitrous Solenoid assembly within reach of the

nitrous feed line and the dry nitrous nozzle. Make

sure that this location is away from moving objects

and will not interfere with closure of the hood.

10. Connect the nitrous feed line to the INLET fitting of

the Performer Nitrous Solenoid. DO NOT use any

thread sealant, since AN fittings are designed as

dry seal fittings.

11. Using your existing blue 3AN line, connect one end

of the line to the OUTLET fitting on the Performer

Nitrous Solenoid.

12. Place the .032” nitrous jet in the EFI nitrous nozzle.

Attached the free end of the blue 3AN line to this

fitting with the jet in place. DO NOT use any type

of thread sealant for this connection.

13. Take the new EFI Vacuum Tee that is supplied with

this kit, and make sure that the .042” jet is installed.

14. Remove the vacuum line from the vehicles fuel

pressure regulator. Install this line on the center

barb of the EFI Vacuum Tee. (NOTE: The center barb

can easily be identified by the anodized nut used to

hold the Fuel Jet.)

15. Measure the correct length of vacuum line from the

barb on the Fuel Pressure Regulator to one port of

the EFI Vacuum Tee. Cut the vacuum line and

install.

16. Measure the correct length of vacuum line from the

barb fitting to the nitrous pressure regulator to the

remaining open port of the EFI vacuum tee. Cut

vacuum line and install.

This concludes the installation of the hardware for your

Dry Nitrous System. After performing these steps, it is

time to do a pressure check on all of the components

that you just installed before completing the system

wiring.

You should check the nitrous system. This should be

checked with the engine OFF. Make sure that all fittings

are tight. Slowly open the bottle valve and walk back

around to the engine compartment. Listen carefully for

leaks. Leaks can be noticed by a slight hissing sound or

by ice forming around fittings. You should hear no

sounds coming from fittings or lines if everything is

connected properly. If leaks are noticed, tighten the

fittings until the leaks seal.

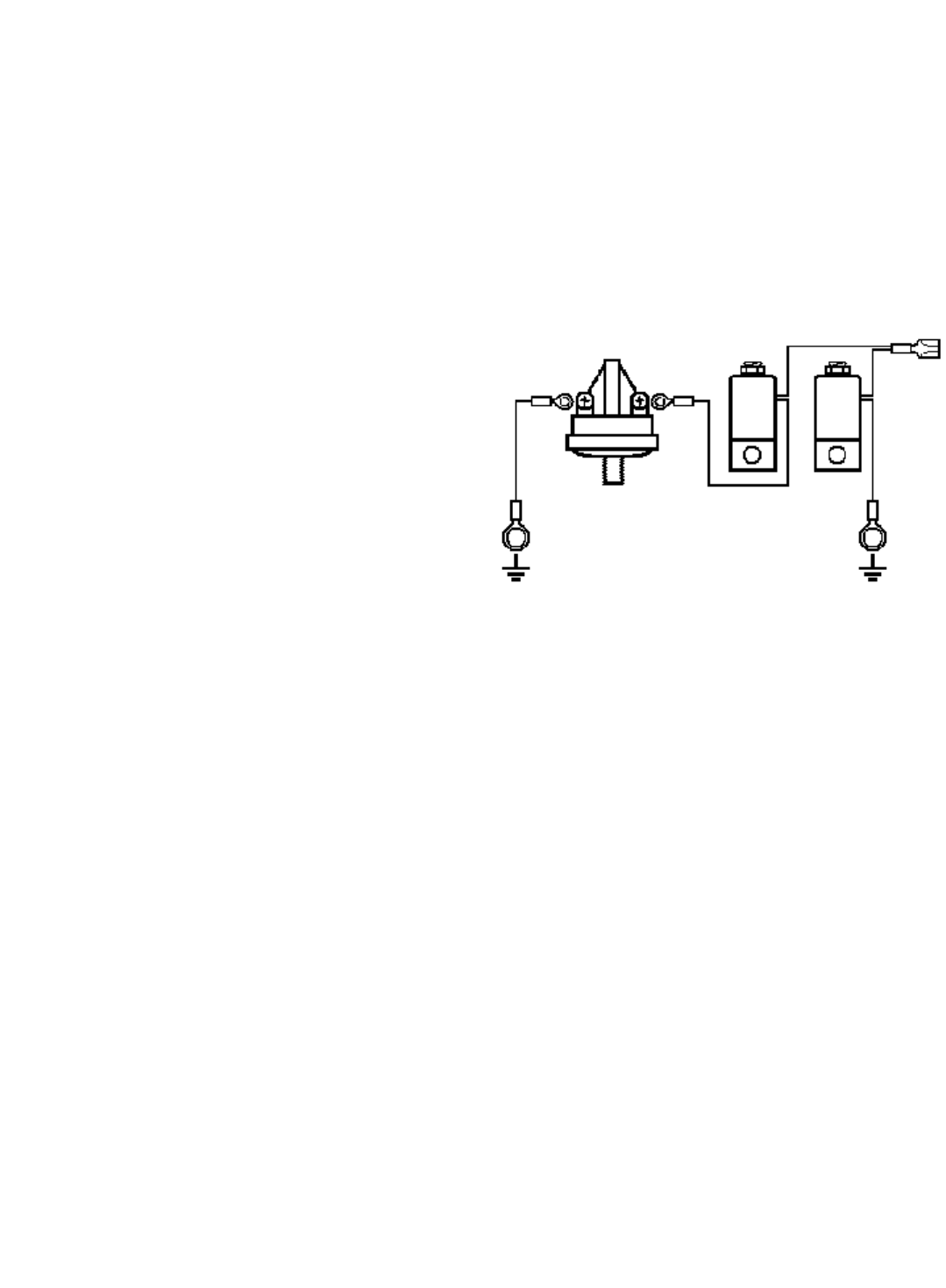

FINAL WIRING

1. Connect one wire from each solenoid to the BLUE wire

routed from the relay wiring harness.

2. Ground the inlet solenoid (the nitrous solenoid that the

feed line leads into) directly to a chassis ground.

3. Connect the remaining wire from the outlet solenoid

(the nitrous solenoid that feeds the nozzle) to the fuel

pressure safety switch.

4. Connect a wire from the remaining terminal of the fuel

pressure safety switch to a chassis ground.

Your Wiring Should Look Like This..

The purpose of the Fuel Pressure Safety Switch is to

prevent the safety solenoid (second solenoid in line) from

opening and filling the manifold with nitrous without

adequate fuel pressure. This switch monitors the fuel

pressure and only actuates over a pre-set fuel pressure.

To test the wiring of your Performer Nitrous Solenoids,

make sure that the bottle valve is in the “OFF” position.

Turn the ignition key to the “ACC.” position. Use a jumper

to connect the two terminals of the fuel pressure safety

switch, therby bypassing the fuel pressure safety switch.

With the arming switch in the “ON” position, quickly tap

the microswitch button to activate the system. You should

hear the first solenoid “click” if wired correctly. Make sure

that you perform this test with the valve OFF to prevent

filling the manifold with Nitrous Oxide. Be sure to remove

the jumper from the fuel pressure safety switch once done

testing the wiring.

To BLUE

wire from

harness

Ground

Ground

First

Nitrous

Solenoid

Second

Nitrous

Solenoid

Fuel Pressure

Safety Switch