©2005 Edelbrock Corporation

Brochure #63-0434

Catalog #71884

Rev. 12/05 - DC/mcPage 2 of 4

INSTALLATION INSTRUCTIONS

DRY COMPONENTS REMOVAL

1. Remove the 3AN nitrous line and 3AN fuel line

currently installed leading from the solenoids to the

wet nitrous nozzle.

2. Remove the wet nitrous nozzle and installed jets

from the nozzle collar. Leave the nozzle collar in

place, but plug using the supplied 1/8” NPT Pipe

Plug. Be sure to use Teflon Paste on the threads of

the pipe plug.

3. Disconnect the 4AN feed line from the nitrous

solenoid. Leave the line in place since this line will

be used for the dry system as well.

4. Disconnect the positive solenoid wires from the blue

wire coming from the relay wiring harness.

5. Disconnect the ground wires from the solenoids.

Make sure that you do not damage the ring terminal

on the nitrous solenoid because this ground will be

re-used when the solenoid is re-installed.

6. Disconnect the fuel solenoid supply hose from

wherever the hose was connected (Usually the test

port on the fuel rail).

7. Install the Fuel Pressure Safety Switch (Hobbs

Switch) in the fitting or port where your wet nitrous

system was getting fuel from (The port or fitting

referred to in step 6).

7. Remove the nitrous and fuel solenoids and brackets

from the engine compartment.

This concludes the removal and disassembly of the wet

nitrous system. From this point on, we will be installing

components for the dry nitrous system. This includes

using both the new components that are supplied with

this kit, as well as re-using certain components that

were supplied with your wet nitrous system such as the

nitrous solenoid and the previous nitrous system wiring.

WET COMPONENTS INSTALLATION

Be sure to ALWAYS use Teflon Paste, not Teflon Tape,

on ALL pipe threads unless directed not to.

1. Using a 7/16” drill bit, drill a hole in the intake boot

next to where the wet nozzle collar is mounted. This

new hole will be where you install the dry nozzle

collar. Once the hole is drilled, be sure to clean out

any shavings, and install the new nut and collar in this

hole. Note the taper in the collar and be sure to install

with this taper facing into the intake boot so the nozzle

can be installed correctly. Tighten the nut onto the

collar securely and then install the dry nozzle into the

collar. Tighten securely, making sure that the nozzle

outlet is facing into the intake manifold.

2. Take the Performer Nitrous Solenoid you are going to

re-use and remove the outlet fitting. Install the steel

tee fitting into the outlet of the solenoid, with the tee

female port facing down.

3. Install the blue 3AN to 1/8” NPT fitting you just

removed into the OUTLET side of the NEW Performer

Nitrous Solenoid.

4. Install the remaining male port of the tee of the

solenoid assembly into the inlet port of the NEW

Performer Nitrous Solenoid.

5. Install the 1/8” NPT nipple into the female port of the

tee of the solenoid assembly.

6. Install the Nitrous Pressure Regulator onto the

1/8” NPT nipple.

7. Install the 1/8” NPT to Barb fitting into the side port of

the Nitrous Pressure Regulator.

8. Install the EFI solenoid bracket to the solenoid

assembly using the supplied solenoid mounting

screws.

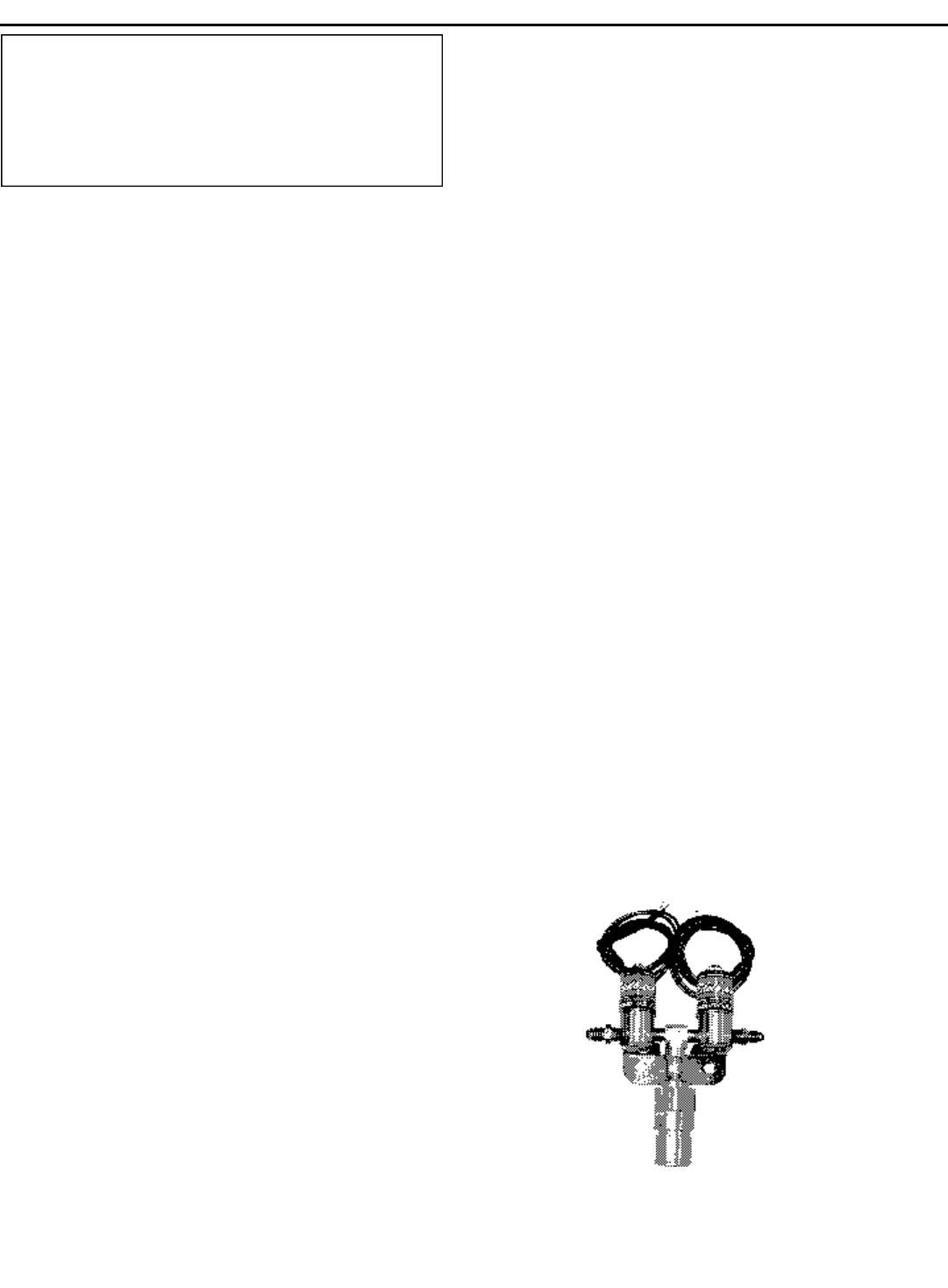

The assembly

should now look

like what is

pictured here.

WARNING!!!

Before performing any of these steps, turn off

the bottle valve and purge the nitrous system of

pressure as well as disconnect the battery.

Failure to do so may cause engine damage

and/or personal injury.