Catalog Part #70402

Brochure No. 63-0164

©2003 Edelbrock Corporation

Rev. 02/03

Page 12 of 25

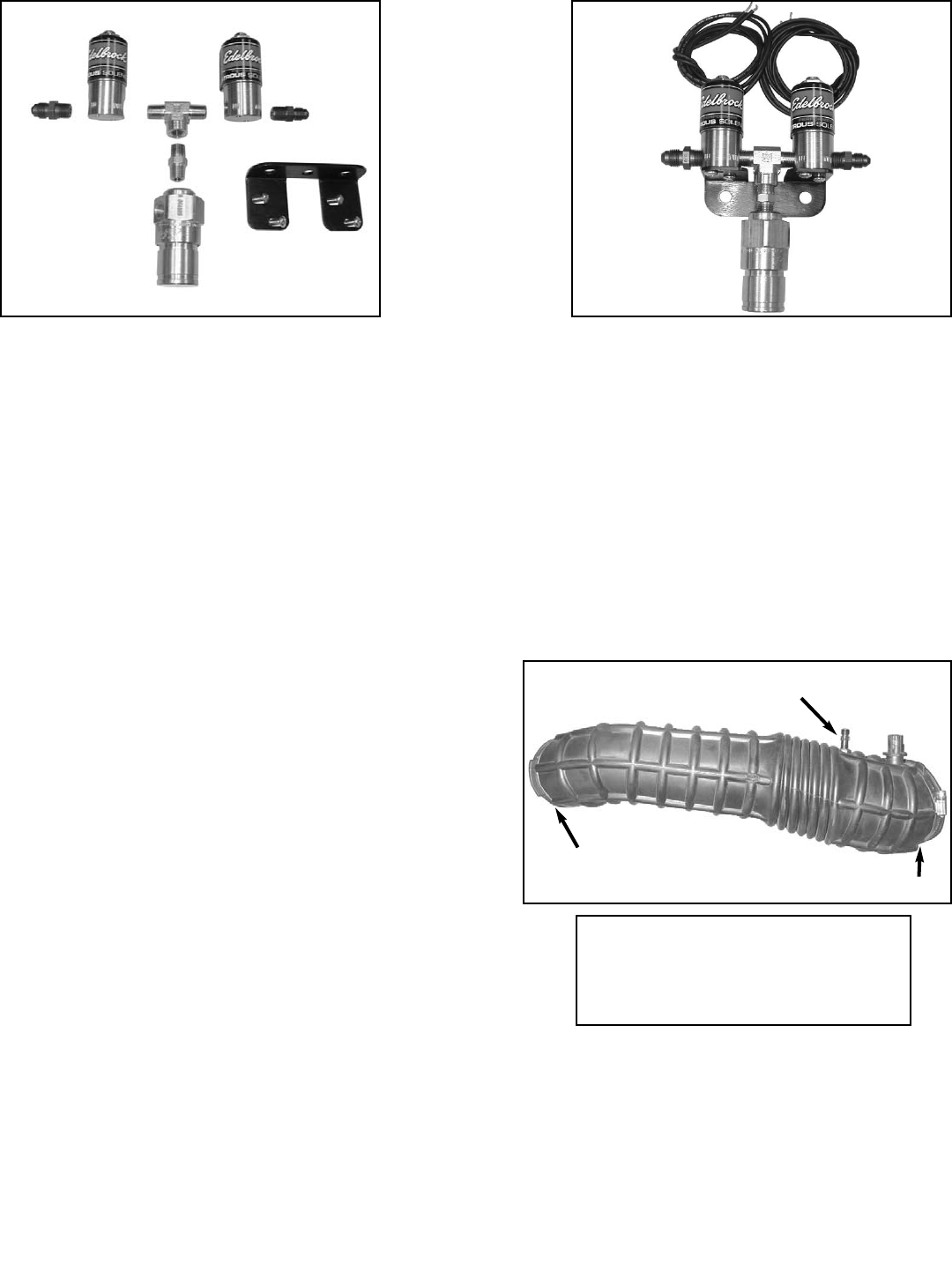

Shown above is a typical EFI solenoid assembly using an unmodified EFI solenoid bracket as well as an exploded view of the nitrous

solenoid assembly. Modifications performed to a solenoid bracket depend on many factors. When mounting the solenoid assembly

on a vehicle, considerations should be taken regarding any potential interference with the vehicle’s systems or components.

The line length between the Performer RPM EFI solenoid assembly and the jet fitting on the nitrous spray nozzle is 24 inches. This

should also be considered when mounting the solenoid assembly.

2.6 Nitrous Spray Nozzle Installation

1. Determine nozzle mounting location in intake boot, between the MAF sensor and the throttle body. Make sure

the nozzle, mounting collar, and the feed line from solenoid to nozzle, do not interfere with any systems or

components of the vehicle such as the hood

latching device.

2. Mark where the nozzle will be placed.

3. Remove the intake boot.

4. Drill a 7/16” hole in the intake boot where nozzle

placement was determined.

5. Be sure to clean out the rubber shavings you

made when drilling to prevent engine damage.

6. Install nozzle mounting nut and collar onto intake

boot.

7. Using liquid Teflon, install the spray nozzle into

mounting collar.

8. Mark the spray direction on the nozzle. Be sure the

nozzle discharge is towards the vehicle’s engine.

9. Install the .039 jet into the nozzle fitting.

10. Install 3AN line from solenoid outlet fitting to spray

nozzle jet fitting and tighten securely.

11. Install the intake boot.

Nozzle

To Throttle Body

From Airbox

Nozzle should be placed in the intake boot so as

to have a clear path to the throttle body. Try to

keep the nozzle from having to travel through the

bend in the intake boot and as close to the

throttle body as possible.