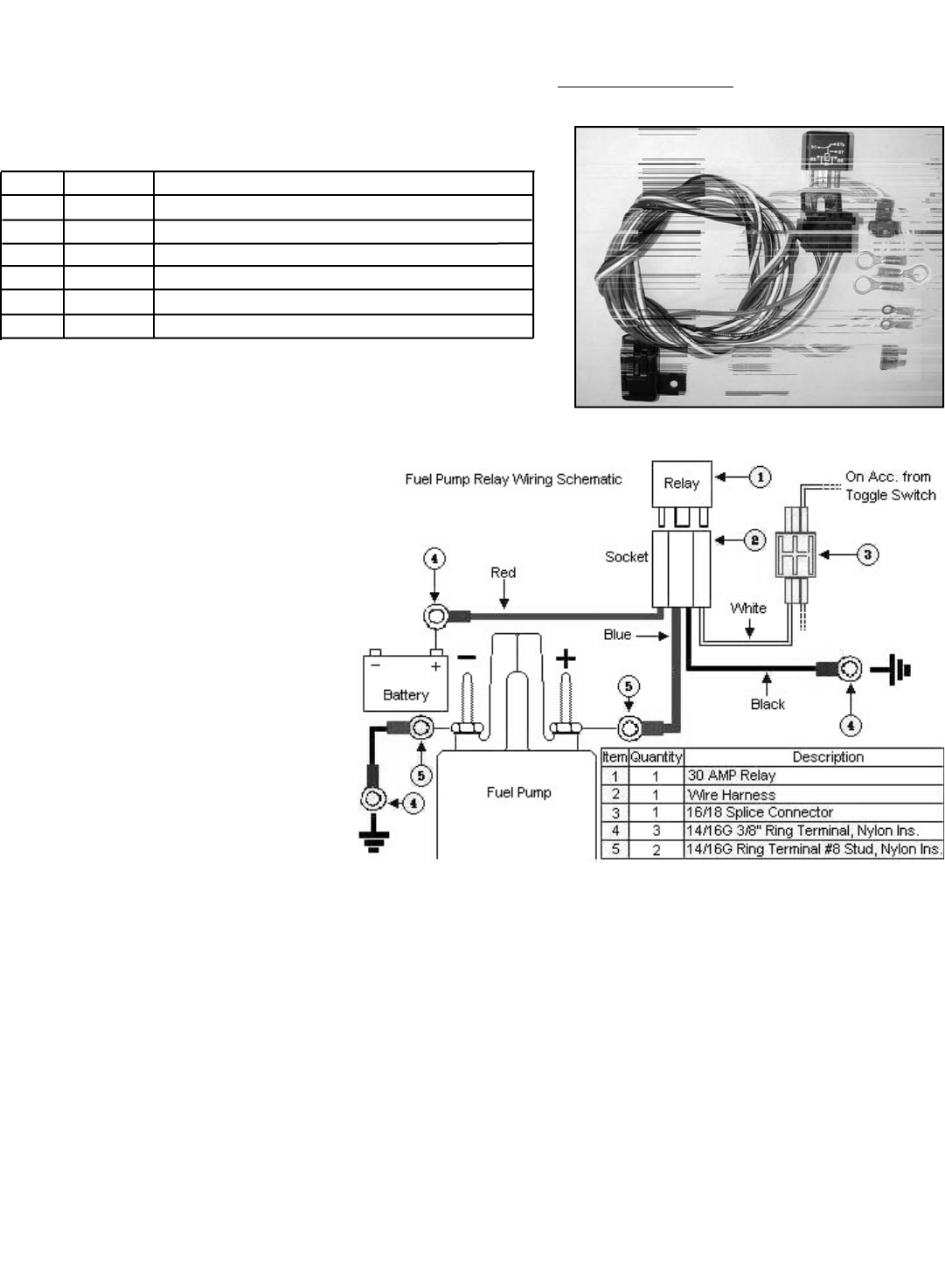

Fuel Booster Pump Electrical Components Bill of Materials

Item # Quantity Description

1 1 ea. 30 amp relay

2 1 ea. Wire harness with integral relay/fuse holder

3 1 ea. 16/18g splice connector

4 1 ea. 14/16g 3/8” ring terminal, Nylon insulated

5 1 ea. 14/16g ring terminal #8 stud, Nylon insulated

6 1 ea. 15 amp ATO blade fuse

©2002 Edelbrock Corporation

Rev. 10/02

Brochure No. 63-0126

Catalog #70206

Page 2 of 4

Fuel Booster Pump Electrical System Installation Procedures

1. Determine the location of the Fuel

Booster Relay and Fuse Holder Wire

Harness. Most common installations

locate these components inside the

driver’s compartment and close to the

fuse panel under the dash. You can also

mount the relay and fuse holder and

harness close to the battery. However,

these connectors are water-resistant, not

water-proof, so care is required when

mounting this assembly under the hood

of your vehicle.

2. The wire harness attached to the relay

and fuse holder includes 8 feet of color-

coded wires to make the electrical

system installation as easy as possible.

We recommend that you do not cut any

lengths of wires from the wire harness or complete the wiring of the fuel booster pump until all of the mechanical components

are securely mounted in their permanent locations.

3. Use the Fuel Pump Relay Wiring Schematic located above along with the Origin and Destination Map on next page to determine

the proper routing for the wires and their locations. Take caution as to not interfere with operating linkages, heat sources,

brackets, etc. Pay particular attention to sharp edges along the route of your wire harness as they can chafe the wire and cause

your system to fail.

4. Once all components have been securely mounted, decide the location of the relay and fuse holder. Secure them with fasteners

(not included with kit) such as sheet metal screws, nuts and bolts, etc. Allow for some slack in the red wire that connects the

relay and fuse holder together.

5. When mounting your relay and fuse holder, make sure the mounting surface is strong enough to support servicing the relay and

fuse. Also, ensure you allow for some slack in the wire that joins the fuse holder to the relay mount. This will avoid any potential

loss of power due to stress on the wire harness. Be sure to cover the fuse with the fuse mount housing.

4. Install the supplied compression fitting adapters to the cut plastic fuel line. Using the supplied fuel line, cut lengths that will

reach from the booster pump to the hose barbs on the compression fittings.

5. Install cut fuel lines and secure using the supplied hose clamps.

6. Check the fuel system for leaks by turning the key to the “On” position. Do not start the engine

. Inspect all fittings and lines

for leaks. Also check wires from time to time for damage or leaks.