Catalog #70080, #70081, #70082, #70083

Brochure No. 63-0312

©2008 Edelbrock Corporation

Rev. 07/08

Page 13

2.4 Nitrous Feed Line Mounting

1. Determine the route your main nitrous feed line will follow. Ensure the path does not route the nitrous feed line too

close to the exhaust system, suspension, electrical lines/components or tires.

2. Attach nitrous supply line to bottle.

3. Feed nitrous line along proposed route.

4. Secure nitrous supply line to underside of vehicle.

Note: Stainless steel covering of the main nitrous feed line is very abrasive. Shield painted components or sensitive

system components like electrical, fuel lines, brake lines or suspension components to prevent them from contacting

main feed line. Rubber hose can be slid over and retained as a chafe guard.

5. Leave nitrous line loose pending installation of nitrous solenoid.

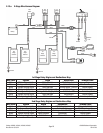

2.5 Single-Stage Solenoid Mounting

Use the following procedures to install the Performer RPM II nitrous solenoid and fuel solenoid.

Note: Remember to use

Teflon paste only on pipe threads. Do not use Teflon tape.

Hint:

Placement of the solenoid is often limited by the lack of possible mounting locations in the engine

compartment. However, if possible, observe the following suggestions:

Solenoid Safety Information

1. Keep solenoids and lines away from exhaust components.

2. Trial fit the solenoids with all lines attached to ensure a proper fit.

3. Solenoids may be mounted sideways or upside-down, if necessary.

2.5.1 Preparing To Mount Your Solenoids

1. Locate the universal solenoid brackets and solenoid mounting screws.

2. These solenoid brackets can be modified to clear almost any potental interference around the carburetor/plate

mounting surface. Please look at the pictures or potential solenoid mounting locations and adapt your brackets

according to the needs of your particular application.

Pictured here is an unmodified Victor Pro solenoid bracket with a modified bracket with solenoid attached, ready for

installation on an intake manifold.

The modifications can be performed by clamping the solenoid bracket in a bench vise, or by using wide jaw pliers.