Catalog # 60219 - #60399

Rev. 3/09 - AJ/mc

Page 3 of 3

©2009 Edelbrock Corporation

Brochure #63-0009

SPECIFICATIONS

Head Bolt Torque: 7/16" bolts - 70/80 ft./lbs. (short/long

bolts)1/2" bolts - 100/110 ft./lbs.

(short/long bolts)

Intake Bolt Torque: 16-18 ft./lbs.

Rocker Studs: 3/8" (#6022, 6025, 6032, 6035)

Rocker Stud Torque: 45 ft./lbs. (7/16"-14; #6022-#6035)

Rocker Pedestal Bolt Torque: 18-20 ft./lbs. (5/16"-18; #6036-39)

Combustion Chamber Volume: 58-60cc

Intake Port Volume: 170cc

Exhaust Port Volume: 60cc

Deck Thickness: 5/8"

Valve Seats: Hardened, interlocking ductile iron,

compatible with unleaded fuels

Valve Size:

#60259, #60359 & #60399: Intake - 2.02", Exhaust - 1.60"

#60229, #60329 & #60379: Intake - 1.90", Exhaust - 1.60"

Valve Locks: 11/32" x 7° (#9611)

Valve Spring Retainers: 7° 4140 steel (#9724)

Valve Spring Diameter: 1.45"

Valve Spring Installed Height: 1.800"

Valve Spring Seat Pressure: 110-120 lbs.

Max. Valve Lift: .575"

Pushrod Guideplates: 5/16" Hardened steel (#6022, #6025,

#6032 & #6035 only)

Rocker Arms: #6022, #6025, #6032, & #6035 accept

stock (except rail style) or aftermarket

roller type#6037, & #6039 accept stock

5.0/5.8L or aftermarket pedestal bolt

down style

Pushrods: #6022, #6025, #6032, #6035 require

5/16" hardened pushrods for use with

guideplates#6037 & #6039 use stock

pushrods

Spark Plugs: 14mm x ¾" reach gasketed seat

Recommended Intake Gasket: Fel-Pro #1250

Recommended Exhaust Gasket: Fel-Pro #1415

Edelbrock Corporation • 2700 California St. • Torrance, CA 90503

Tech Line: 800-416-8628 • Office: 310-781-2222

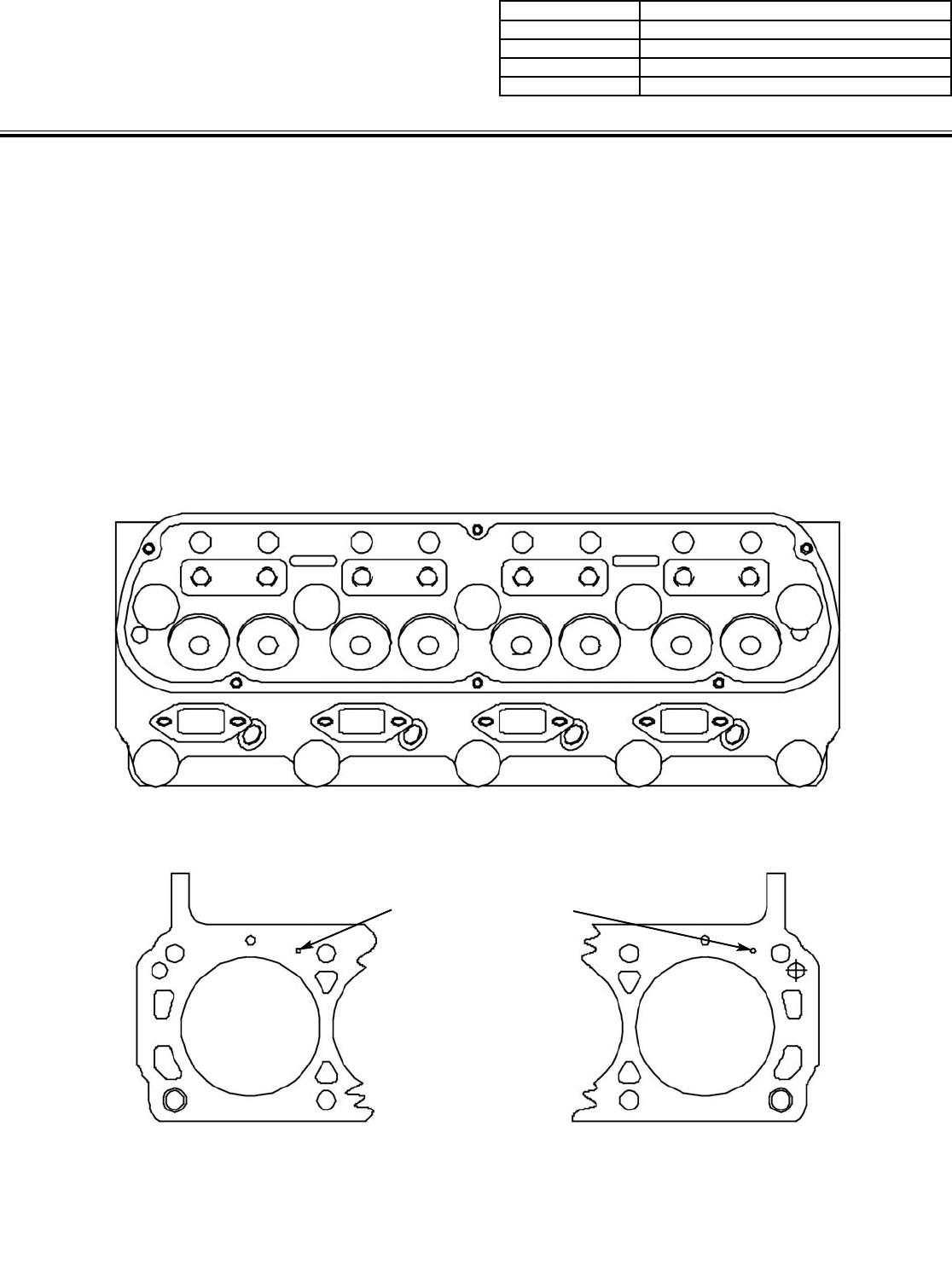

Figure 2 - Steam Hole Locations for Early 289 & 302 Engine Blocks

Figure 1 - Head Bolt Tightening Sequence

95137

10 6 2 4 8

#5 Cylinder

Front Cylinder

LH Bank

(Driver Side)

#1 Cylinder

Front Cylinder

RH Bank

(Pass. Side)

1/8” Holes Drilled

into the Water Jacket.

Position Hole Location

Using the Head Gasket.

• Edelbrock offers cylinder heads machined to the proper

specifications for use with Fel-Pro Locwire head gaskets only

as shown in the table to the right:

Standard Head # Machined for Locwire Head Gaskets

60259 60269

60359 60279

60379 60289

60399 60299