16

Edelbrock Performer Series Carburetor Owner’s Manual Rev 1/01

* = Carburetor is certified to meet U.S. Coast Guard Requirements

The length of time during which the choke will stay closed is determined by the position of the choke

cap. As the choke cap is turned clockwise the choke will stay closed longer. To properly set the choke

turn the choke cap to the leanest notch on the choke housing, loosen the choke housing retaining

screws, and run the engine until normal operating temperature is reached. With the engine running,

slowly turn the choke cap clockwise until the choke valve begins to close. Now turn the choke

housing one notch counterclockwise (LEAN) and tighten the choke housing retaining screws. Periodic

readjustment of the choke will be required as the temperature changes throughout the year. After

each adjustment verify that the choke valve opens fully after the engine is warm.

SPECIAL CALIBRATIONS

The preceding calibrations and adjustments apply to carburetors used in general street applications.

In the following extreme instances, special calibration procedures may need to be followed.

Off-Road

Although the Edelbrock Performer Series carburetor was not calibrated with hill climbing and other

extreme off-road operation in mind, it can be made to perform superbly by substituting Edelbrock

#1465 spring loaded needle and seat for the original needle and seat. The spring loaded needle and

seat act like a shock absorber, reducing the possibility of flooding during off-road operation. After

installation of the new needle and seat you must reset the float level to 7/16" and drop the float drop

to 15/16 to 1" as outlined in “FLOAT ADJUSTMENT”.

High Fuel Flow

When evidence of fuel starvation exists, first ensure that proper pressure (4-5 psi minimum) is

maintained at WOT. If proper fuel pressure is supplied and fuel starvation still exists, it may be

necessary to change the needle and seat to a larger size (#1466). Do not make this change unless

absolutely required, as the smaller inlet is preferred for proper fuel control under most conditions.

High Altitude

Altitude has a direct effect on the operation of most carburetors. As the altitude increases, the air

becomes less dense so a carburetor, originally calibrated at low altitude, delivers too much fuel and

the engine runs richer. If the preceding tuning procedure is performed on an Edelbrock Performer

Series carburetor, a proper high altitude calibration will result. If the vehicle was calibrated at lower

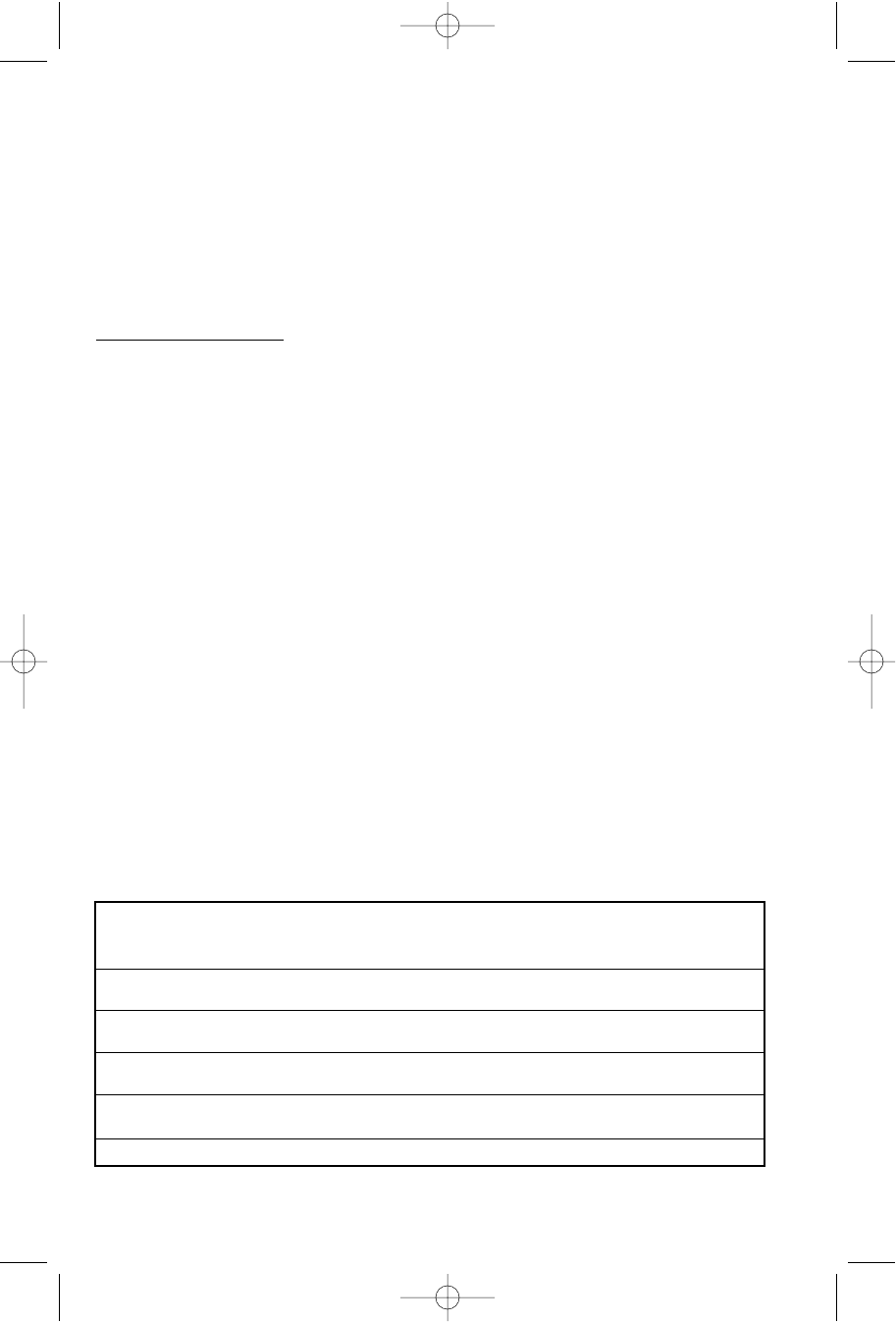

Carburetor CFM Main Main Metering Step-Up Needle Float

Part No. Jet Jet Rod Spring & Seat Height

Primary Secondary (Primary only)

1404 500 .086" .095" .065" x .052" orange (5") .0935" 7/16"

1405 600 .100" .095" .070" x .047" orange (5") .0935" 7/16"

1406 600 .098" .095" .075" x .047" yellow (4") .0935" 7/16"

1407 750 .113" .107" .071" x .047" orange (5") .0935" 7/16"

1409* 600 .098" .101" .068" x .047" orange (5") .0935" 7/16"

1410* 750 .113" .107" .071" x .047" orange (5") .0935" 7/16"

1411 750 .110" .107" .075" x .047" orange (5") .0935" 7/16"

1412 800 .113" .101" .071" x .047" orange (5") .0935" 7/16"

1413 800 .113" .101" .071" x .047" orange (5") .0935" 7/16"

Carburetor Specifications - All Models

1403-1413 Perf Series Carburetor Owner's Manual.qxd 3/31/2006 12:10 PM Page 16