6

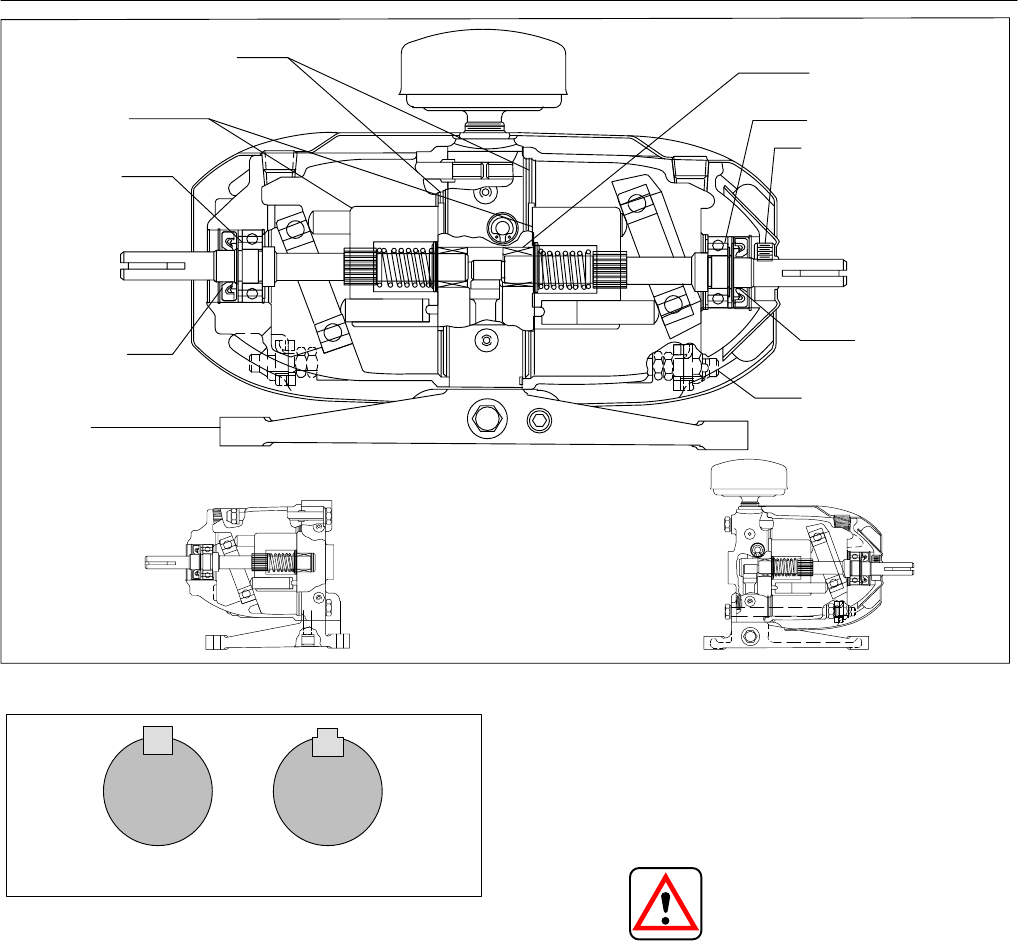

Figure 1

Needle Bearings

Replace Bushing

Improved

Cylinder Block

Motor

End

(B)

Heavier

Snap Ring

Improved Valve Block

Eliminates Valve Plate

Motor

Heavier Snap Ring

Fan Secured by Set

Screws

Pump

End

(A)

Improved

Seal

Improved Draw

Bolt Design

Pump

Improved

Seal

New

Heavier

Mounting

Figure 2

Standard Key Step Key

D. Circuit Connection

Connections between the pump and motor of the TR3 unit

are self-contained. When the PTR3 pump and MTR3 motor

are connected together, they should be connected in a

closed circuit. Supercharging pressure (30 psi) is provided

by an integral supercharging pump in the PTR3 unit. If the

PTR3 pump is used in an open circuit, the inlet must be

superchrged at 30 psi. The MTR3 motors can either be used

in a closed circuit supercharged at 30 psi or in an open

circuit with a means of maintaining 30 psi back-pressure at

the outlet.

E. Power Source

This should be an 1150-1800 rpm electric motor or

equivalent. The source must supply 1/4 horsepower more

than the required output.

F. Load

The maximum load which may be driven by these units is

3/4 horsepower. The 40 inch pounds of torque output will

equal more than 3/4 horsepower at 1800 rpm, and must be

considered available for starting or short intervals only.

CAUTION

Stalling the output shaft for any length of time

should be avoided. Pump delivery passing over the

relief valve generates heat, which can cause

damage to these units.

G. Direction of Rotation

Pump (input) shaft rotation can be clockwise or

counterclockwise. The direction of motor (output shaft)

rotation is changed by actuating the pump control to the

other side of neutral.