5

If any parts must be pressed from a shaft or from the

output hub, this should be done before ordering parts to

make sure that none of the bearings or other parts are

damaged in removal. Do not press against outer race of

any bearing.

Because old shaft oil seals may be damaged in

disassembly, it is advisable to order replacements for

these parts.

Removing Reducer from Shaft

CAUTION: Remove all external loads from drive before

removing or servicing drive or accessories.

WARNING: To ensure that drive is not unexpectedly

started, turn off and lock out or tag power source before

proceeding. Failure to observe these precautions could

result in bodily injury.

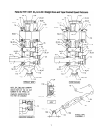

Straight Bore: Loosen screws in both output hub collars.

Remove the collar next to the end of the shaft. This

exposes three puller holes in the output hub to permit the

use of a wheel puller. In removing the reducer from the

shaft, be careful not to damage the ends of the hub.

Taper Bushed:

1. Remove bushing screws.

2. Place the screws in the threaded holes provided in

the bushing flanges. Tighten the screws alternately and

evenly until the bushings are free on the shaft. For ease of

tightening screws, make sure screw threads and threaded

holes in bushing flanges are clean.

3. Remove the outside bushing, the reducer, and then

the inboard bushing.

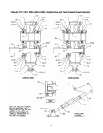

Disassembly:

1. Position the reducer on its side and remove all

housing bolts. Drive dowel pins from housing. Gently tap

the output hub and input shaft with a soft hammer

(rawhide, not a lead hammer) to separate the housing

halves. Open housing evenly to prevent damage to the

parts inside.

2. Lift shaft, gear, and bearing assemblies from

housing.

3. Remove seals from housing.

Reassembly:

1. Output Hub Assembly: Heat gear to 325°F to 350°F

to shrink onto hub. Heat bearings to 270°F to 290°F to

shrink onto hub. Any injury to the hub surfaces where the

oil seals rub will cause leakage, making it necessary to

use a new hub.

2. Countershaft Assembly: Shaft and pinion are integral.

Press gear and bearings on shaft. Press against inner (not

outer) race of bearings.

3. Input Shaft Assembly: Shaft and pinion are integral.

Press bearings on shaft. Press against inner (not outer)

race of bearings.

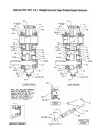

4. Drive the two dowel pins into place in the right-hand

housing half. Apply RTV732 sealant to carriers for R.H.

side(backstop side) of reducer. Install carriers and torque

bolts per table 4.

5. Place R.H. housing half on blocks to allow for

protruding end of output hub.

6. Install bearing cups in right-hand housing half,

making sure they are properly seated.

7. Mesh output hub gear and small countershaft gear

together and set in place in housing. Set input shaft

assembly in place in the housing. Make sure bearing

rollers (cones) are properly seated in their cups. set

bearing cups for left-hand housing half in place on their

rollers.

8. Clean housing flange surfaces on both halves,

making sure not to nick or scratch flange face. Place a

1/8 bead of RTV732 sealant on flange face. (make sure

RTV is placed between bolt holes and inside of flange

face) Place other housing half into position and tap with a

soft hammer (rawhide, not lead hammer) until housing

bolts can be used to draw housing halves together.

Torque housing bolts per torque values listed in table 4.

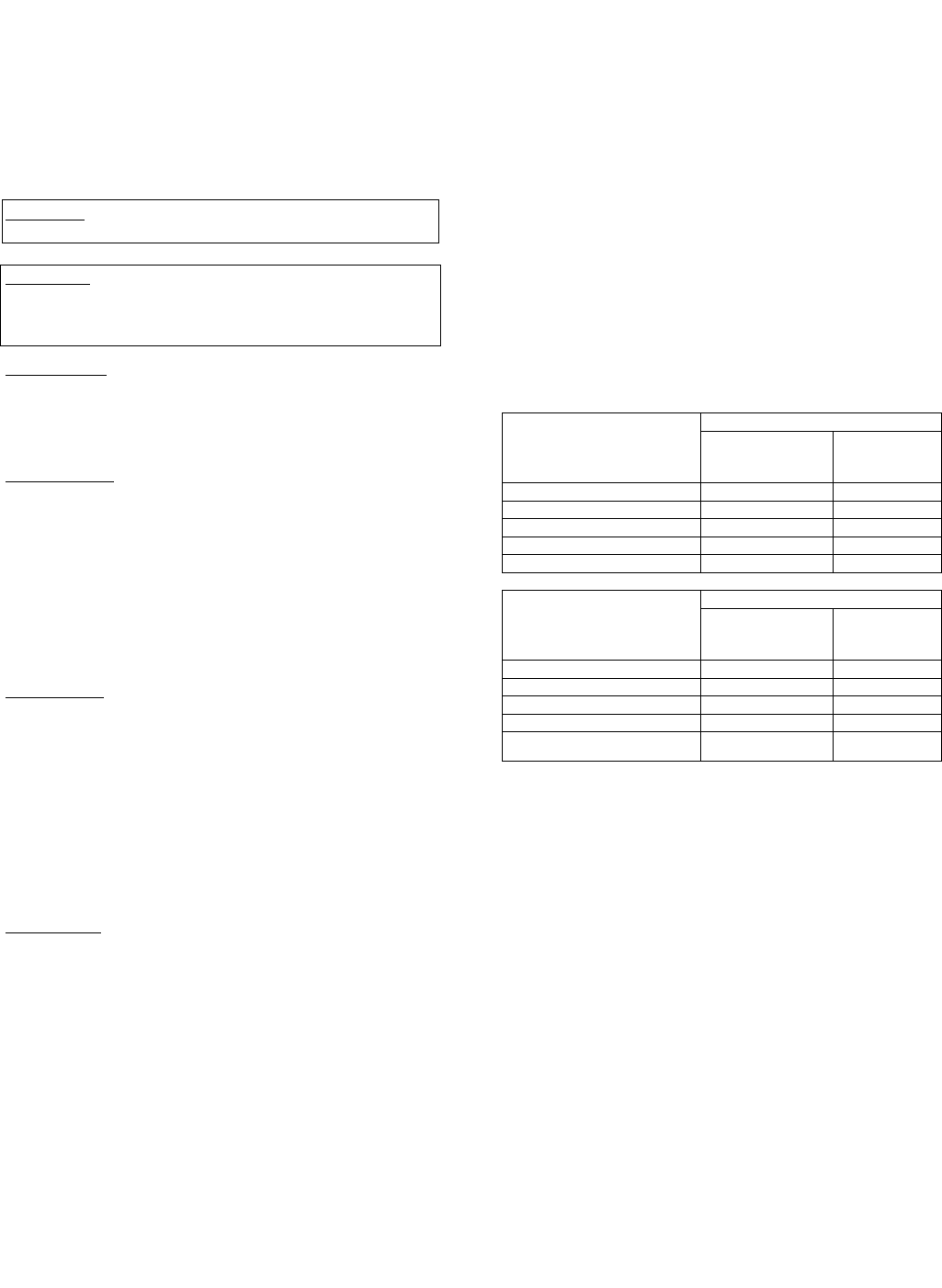

Table 4 – Recommended Torque Values

Dry Torque (lb.–ft.)

Reducer

Size

Housing

Bolts

Output Hub

Seal Carrier

Screws

TXT / HXT 305A & 3A 50–45 17–15

TXT / HXT 405A & 4A 50–45 30–27

TXT / HXT 505A & 5B 75–68 30–27

TXT605 & TXT / HXT 6 75–68 30–27

TXT705 & TXT / HXT 7 150–135 50–45

Dry Torque (lb.–ft.)

Reducer

Size

C’shaft

Bearing Cover

Screws

Input Shaft

Seal Carrier

Screws

TXT / HXT 305A & 3A 17–15 17–15

TXT / HXT 405A & 4A 30–27 30–27

TXT / HXT 505A & 5B 30–27 30–27

TXT605 & TXT / HXT 6 30–27 30–27

TXT705 & TXT / HXT 7

50–45 50–45

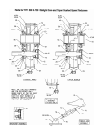

9. Place output hub seal carrier in position without

shims and install two carrier screws diametrically opposed.

Torque each screw to 25 in.-lbs. Rotate the output hub to

roll in the bearings and then torque each screw to 50 in.-

lbs. Again turn output hub to roll in the bearings. With a

feeler or taper gage, measure the gap between the

housing and the carrier flange. To determine the required

shim thickness, take the average of the two feeler gage

readings. Remove carrier and install the required shims

plus .002. Install carrier with shims and torque bolts per

table 4. Rotate hub assy, tap lightly with rawhide mallet on

end of hub, while rotating, to ensure bearings are seated.

Using a dial indicator check end play of hub bearings,

endplay should be .001-.003. Repeat this process as

necessary to obtain proper end play. Place a 1/8 diameter

bead of RTV732 sealant inside the carrier at the shim I.D.

and install carrier on reducer housing. Torque carrier bolts

to value shown in Table 4.

10. Adjust the countershaft bearings using the same

method as in step 8 above. The axial end play should be

.001” to .003”.

11. Again, using the same procedure as in step 8,

adjust the input shaft bearings, except the axial end play

should be .002” to .004”.