DOORS 9P – 11

DAEWOO M-150 BL2

D109C577

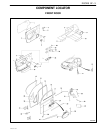

5. If a fore or aft adjustment is required, use the following

steps:

D Remove the striker screws (1).

D Remove the spacer in order to move the striker to-

ward the rear of the vehicle (2).

D Add a 2 mm (0.08 inch) spacer in order to move

the striker toward the front of the vehicle.

D Install the striker screws.

6. Perform the up/down or the in/out adjustment. Refer

to ‘‘Up/Down or In/Out Adjustment’’ in this section.

D109C574

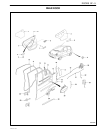

Up/Down or In/Out Adjustment

An adjustment of the striker in the up and down or in and

out directions may be necessary for a number of reasons:

vehicle frame damage as the result of a collision, installa-

tion of new door weatherstripping, customer complaints

of excessive windnoise, or difficulty in opening or closing

the door. In order to adjust the door striker in an up and

down or in and out direction, perform the following proce-

dure:

1. The door must be properly aligned.

2. Loosen the striker screws.

3. The floating cage plate can be moved slightly using

the ends of the striker screws. Move the floating cage

plate to the desired position.

Notice: It is important to use a flat-end rotary file in or-

der not to damage the tapped floating cage plate. The

striker screws and the tapped floating cage plate are im-

portant attaching parts that could affect the performance

of vital components and systems.

4. If proper adjustment requires that the floating cage plate

be moved more than is possible, use an electric hand

drill and a 3/8- inch rotary file with a flat head in order to

enlarge the body opening in the direction required.

5. Tighten the striker screws to the correct position.

D109C578

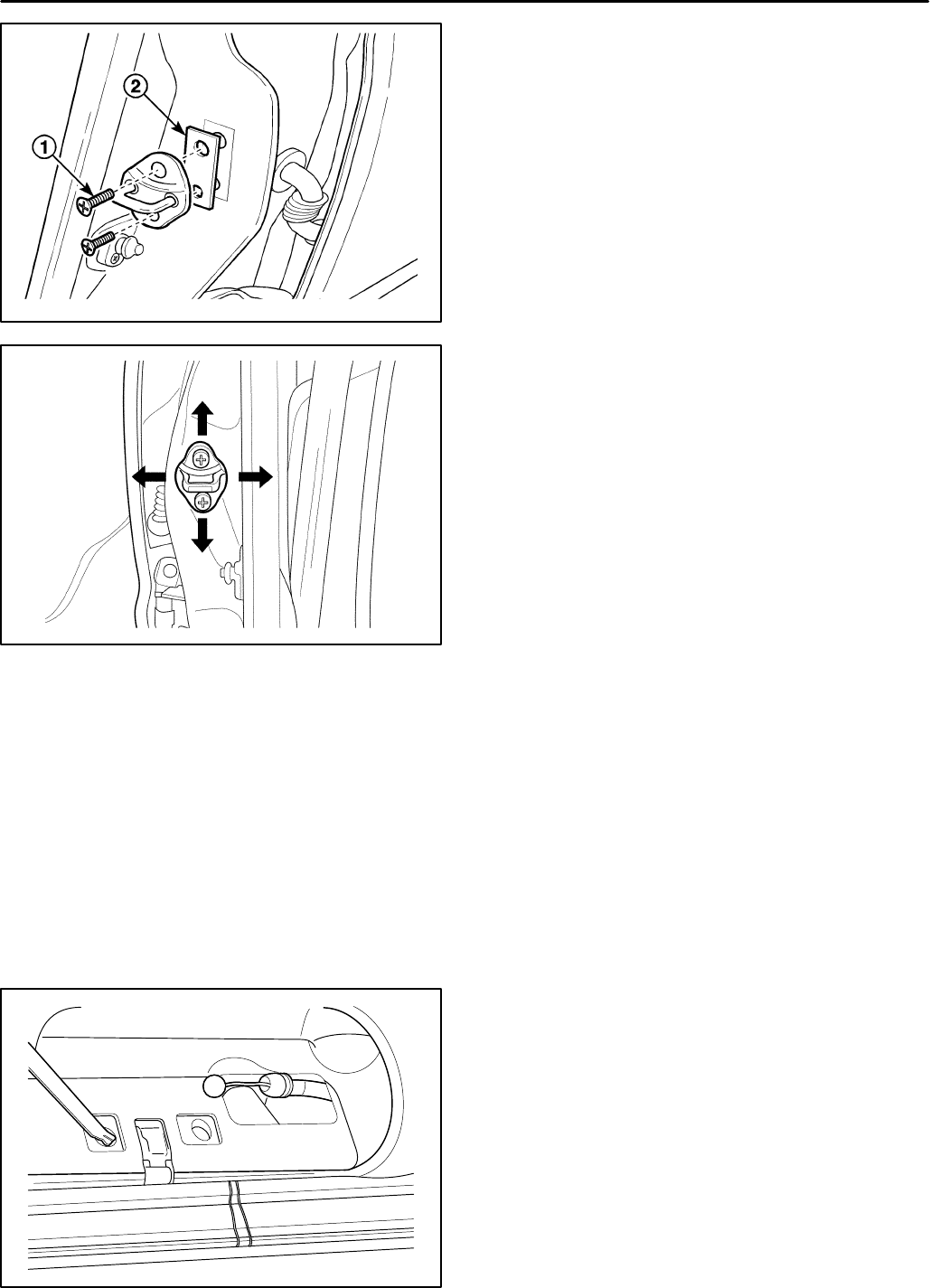

TAILGATE LOCK STRIKER

ADJUSTMENT

Notice: The tailgate lock striker is an important attaching

part that can affect the performance of vital components

and systems and can cause major repair expenses. If re-

placement becomes necessary, the tailgate lock striker

must be replaced by one with the same part number or

with an equivalent part if replacement becomes neces-

sary. Do not use a replacement part of lesser quality or of

a substitute design. The specified torque values must be

used during reassembly in order to ensure the proper

retention of the part.