PW 3500 Series

Technical Information

Operator Controls

The PW 3500 Series has a

refined control handle, which

improves operator comfort and

productivity.

The Crown PW 3500 Series has

dual, soft urethane twist grips

with automatic return to neutral

when released. Two textures and

a unique “cam” design aid in

plugging, steering and long dis-

tance travel. On the control pod

are full width raise, lower and

horn buttons for easy actuation.

Third speed selector in control

handle may be used to shut off

high speed when operating in

congested areas. Reversing

button in control handle reverses

direction of travel, if button should

come in contact with operator.

Electrical System

24-volt electrical system

(PW 3520-60/80)

12-volt electrical system

(PE 3510-60)

Series-wound, high-torque, fan-

cooled, Crown manufactured

drive motor for reliability and

ease of service.

Series-wound, high-torque,

lift motor

Traction control systems:

Resistor control has four heavy-

duty contactors with silver tips.

Solid-state time relay on resistor

control between 2nd and 3rd

speeds

provide controlled

acceleration. Resistor is

standard on the PW 3500

Series. Transistor control is

optional on 24-volt models.

Transistor control has many

benefits; maximum energy effi-

ciency, reduced maintenance

and infinite speed control.

Crown transistor controls feature

a 250 amp rated system; a

bypass contactor for maximum

current in heavy loading, ramping

applications; arc-less contactor

operation; ramp start; and a

sealed enclosure that protects

the transistor control from water,

contaminants, etc.

Lift limit switch operates at

maximum lift height to shut off

pump motor.

Control and power circuits

are fused.

To facilitate pallet entry/exit

Crown has engineered several

features into their fork assembly.

Standard-tip forks have pallet

entry rollers to lift fork over

bottom board of pallet. Rollers

are made of high molecular

weight polyethylene with .75"

axle and roll pin.

Abrasion-resistant steel entry/exit

slides on both sides of each fork

have convex bottom surfaces to

prevent snagging as forks move

over bottom boards of pallet.

One piece design with radiused

edges are welded away from

contact point of slide.

New exit roller design prevents

load wheel from dropping after

crossing bottom board. The 4"

wide, steel exit roller is posi-

tioned directly behind the load

wheel to

keep the fork rolling.

New entry/exit

slide design also

assists in trouble free pallet

entry/exit.

Fork adjustment is done at the

toe with no need to remove a

cover plate. Fork heel height

adjustment is done quickly with-

out removing battery. Quick and

easy fork adjustment promotes

servicing of fork assembly to

keep pallet entry/exit productive.

Pull rod design incorporates a

replaceable “tenon” design for

fast servicing of pull rod while

still in the truck.

Power Unit Structure

Rugged steel doors are sus-

pended on heavy-duty pin

hinges. Doors swing wide for

good access. Doors also can be

lifted off for unrestricted service

access. Door bolts have exclu-

sive convex design that mates

with concave door holes for fast

reinstallation of bolts. Heavy-steel

skirt surrounds entire area.

Brake

Internal expanding mechanical

brake with 4.5" drum and

bonded brake linings. Brake

drum is mounted on drive

motor shaft and braking effort

is transmitted through the gear

reductions. Brake is actuated by

control handle position.

Power disconnect

All wiring color coded

Key switch

175 amp SB connector

(PW 3520-60/80) 350 amp

connector (PW 3510-60)

Horn

Hydraulic System

Heavy-duty pump, motor,

reservoir and control are assem-

bled into one unit. A centrally

located lift cylinder,

mounted

vertically, is equipped

with long-

life polyurethane packing.

Pressure-compensating flow

control valve is intergal part

of valve block and regulates

maximum lowering speed.

Overload valve protects

hydraulic components.

Drive Unit

All gear drive from drive motor to

drive wheel axle. Drive tire axle

is mounted in the drive unit on

both sides for maximum strength

in rough floor or docking appli-

cations. Drive unit is top and

bottom mounted. Top mount is

a large, tapered roller bearing for

vertical or horizontal forces.

Bottom mount has four shock

mounted rollers on drive unit

running in a hardened steel roller

race. Gear train runs in oil-filled,

sealed housing.

Caster System

Crown has designed two

optional caster systems for the

PW 3500 Series to meet high-

volume warehouse requirements.

Option 1: Quick adjustment

casters enable braking, traction,

steer effort and stability to be

“balanced” based on your

specific applications.

Option 2: All of the advantages

of quick adjustment casters are

yours, in addition to a torsion

bar suspension that maximizes

stability on tall, unwieldy and less

stable loads.

Fork Assembly

Fork width - 9.12" on standard-

tip fork models, fork spread - 22"

and 27" standard on standard-

tip models. 23" - 26" spread

available in one-inch increments.

Pallet Planning Guide

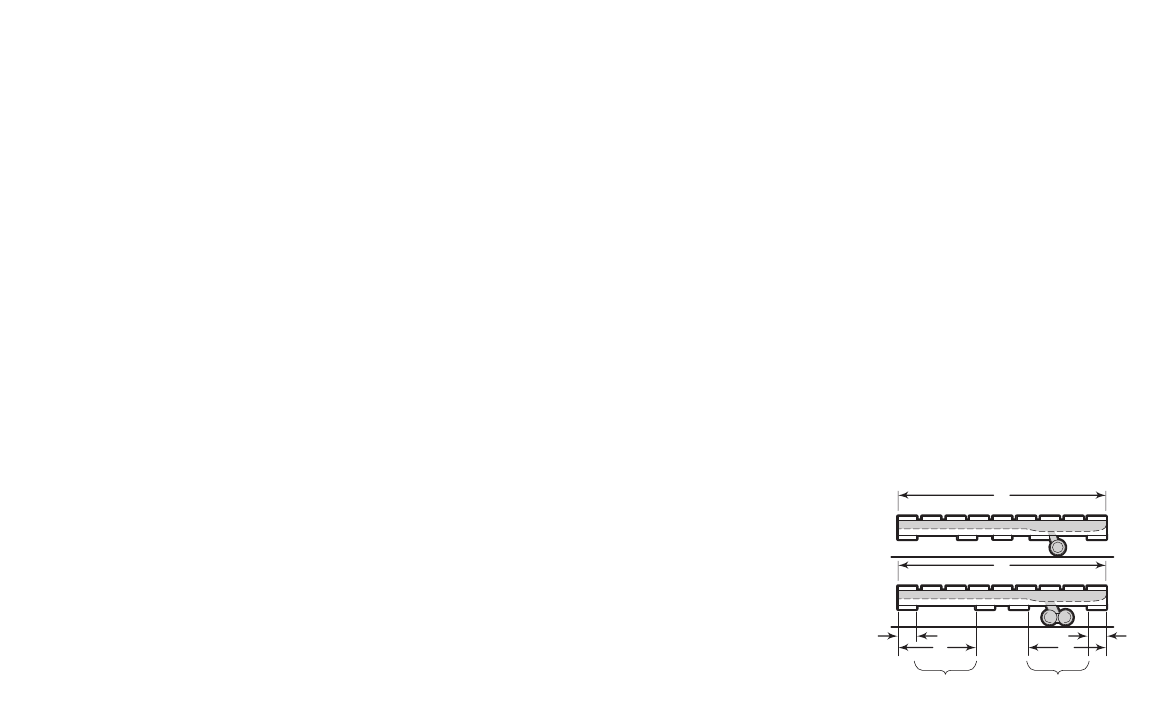

On PW models, the load wheel

will drop in the second opening

of the pallet. When “A” dimen-

sion equals nominal fork length,

“C” dimension is 6" maximum

and “B” is 14" minimum. On

models with tandem load

wheels, the “C” dimension

should be 6" maximum and the

“B” dimension should be 17"

minimum. Customers that need

tandem load wheel trucks, but

use pallets with smaller open-

ings, may be accommodated if

the maximum lift height of the

truck is reduced. Contact your

local Crown dealer for details.

Other Options

1. Audible travel alarm

2. Flashing lights

Safety considerations and

dangers associated with

audible travel alarms and

flashing lights include:

• Multiple alarms and/or lights

can cause confusion.

• Workers ignore the alarms

and/or lights after day-in and

day-out exposure.

• Operator may transfer the

responsibility for “looking out”

to the pedestrians.

• Annoys operators and

pedestrians.

Dimensions and performance

data given may vary due to

manufacturing tolerances.

Performance is based on an

average size vehicle and is

affected by weight, condition of

truck, how it is equipped and the

conditions of the operating area.

Crown products and specifica-

tions are subject to change

without notice.

C

Crown Equipment Corporation

New Bremen, Ohio 45869 USA

Tel 419-629-2311

Fax 419-629-3796

crown.com

Because Crown is continually improving its products,

specifications are subject to change without notice.

Crown and the Momentum symbol are trademarks of

Crown Equipment Corporation.

Copyright 1993-2005 Crown Equipment Corporation

SF12156 Rev. 4/05

Printed in U.S.A.

A

A

BB

CC

First

Opening

Second

Opening