{ CAUTION:

Wheel nuts that are improperly or incorrectly

tightened can cause the wheels to become loose or

come off. The wheel nuts should be tightened with a

torque wrench to the proper torque specification

after replacing. Follow the torque specification

supplied by the aftermarket manufacturer when

using accessory locking wheel nuts. See Capacities

and Specifications on page 5-114 for original

equipment wheel nut torque specifications.

Notice: Improperly tightened wheel nuts can

lead to brake pulsation and rotor damage. To avoid

expensive brake repairs, evenly tighten the wheel

nuts in the proper sequence and to the proper torque

specification. See Capacities and Specifications on

page 5-114 for the wheel nut torque specification.

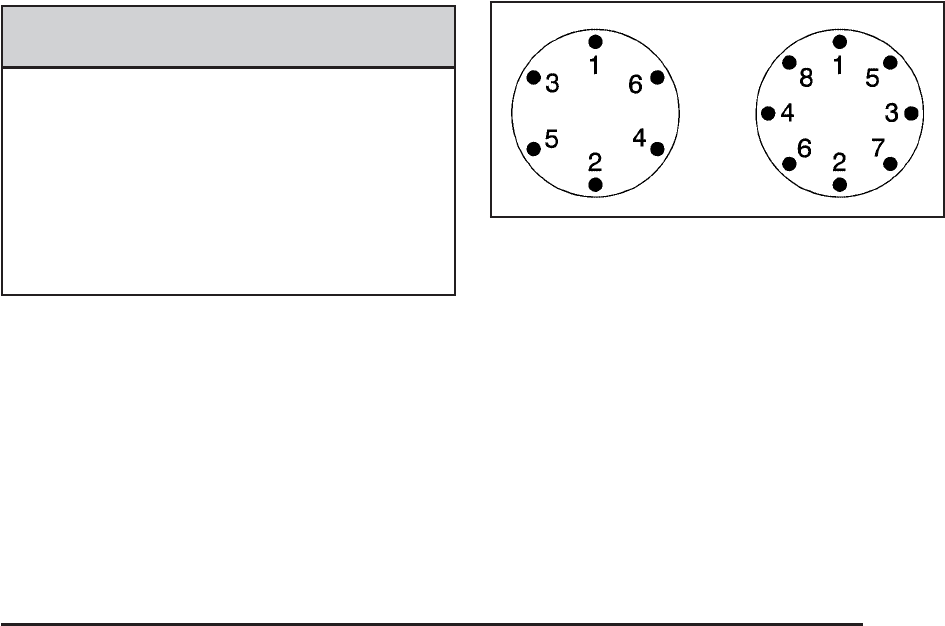

11. Use the wheel wrench to tighten the nuts firmly.

Turn the wheel wrench clockwise and in a

crisscross sequence as shown.

12. Put the wheel cover or the center cap and plastic

wheel nut caps back on. Remove any wheel blocks.

Have a technician check the wheel nut tightness of

all wheels with a torque wrench after the first

100 miles (160 km) and then 1,000 miles (1600 km)

after that. Repeat this service whenever you have

a tire removed or serviced. See Capacities and

Specifications on page 5-114 for more information.

5-93