C. Lower boom until parking stands contact

ground.

D. Extend bucket cylinders until cutting edge of

bucket is frimly on the ground.

E. Remove pin from mounting bracket.

G. With tractor at idle speed, roll bucket back

until subframe raises up off rear bracket.

H. With tractor at idle speed, carefully activate

boom cylinder until cross tube is free of pressure

within front bracket channel. It may be necessary to

roll bucket back further to maintain sufficient clear-

ance between subframe and rear cross tube.

I. Disconnect hydraulic hoses from tractor quick

disconnect couplers.

J. Carefully back tractor out of loader.

NOTE

When dismounting the 2426 QT from certain tractor

models, additional subframe height is required to

clear the front axle. This may be done by rotating the

subframe back by extending the boom cylinders

once the cross tube is free of the front channel.

K. Reinstall cuffs to loader subframe and place

pin in front mounting bracket for storage.

L. Clean all dirt and debris from loader. Dirt will

hold moisture and cause rust.

M. If loader is to be stored for an extended period

of time, perform lubrication per paragraph 4-2. Also

apply coat of heavy grease to exposed cylinder rods

to prevent rusting.

Figure 2-8 Mounting Bracket

USE CAUTION WHEN DISMOUNTING

LOADERS EQUIPPED WITH OPTIONAL

CONTROL VALVE ON TRACTORS

EQUIPPED WITH CANOPY. RAISING

LOADER SUBFRAME TOO HIGH CAN

PINCH HAND BETWEEN CONTROL HAN-

DLE AND CANOPY CAUSING INJURY.

WARNING

F. Loosen nut securing cuffs to loader subframe.

Remove pin securing cuff. Remove cuff. (Figure 2-4)

Pin

SECTION III

OPERATING INSTRUCTIONS

3-1 GENERAL SAFETY

Only qualified people familiar with this operator’s

manual should operate this machine. Operator

should wear hard hat, safety glasses, and safety

shoes. The operator should read, understand and

practice all safety messages shown on the caution,

warning and danger decals affixed to the loader to

avoid serious injury or death. It is recommended that

tractor be equipped with Rollover Protective System

(ROPS) and a seat belt be used. Check for ditches,

stumps, holes or other obstacles that could upset

tractor or damage loader. Always turn off tractor

engine, set parking brake, and lower loader to

ground before leaving tractor operator’s seat.

3-2 OPERATION

The loader should be operated with the tractor

engine running at 1200-1700 rpm. Excessive

speeds are dangerous and may cause bucket

spillage and unnecessary strain on both the trac-

tor and loader.

When operating in temperatures below 30°F (-1°C.),

run the tractor engine below 1200 rpm until the oil

temperature exceeds 30°F.

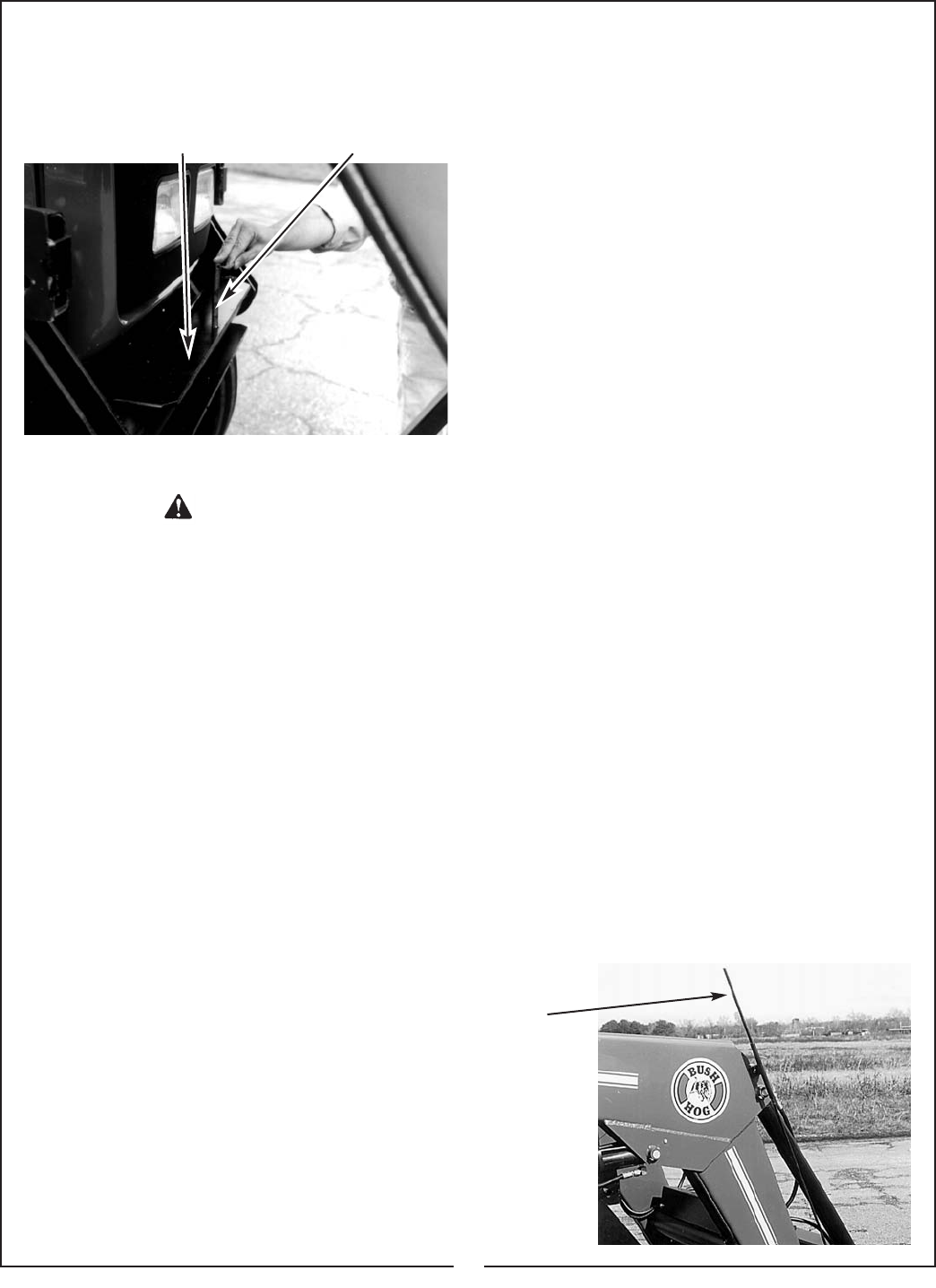

A bucket level, indicator rod (Figure 3-1) located on

the loader frame can be used to determine bucket

angle. Before beginning work, observe the position

of indicator rod with bucket flat on ground. Raise

boom to several different positions. At each position

level bucket, then observe the indicator rod. Once

familiar with the indicator rod positions, operation of

loader will be easier and more efficient.

The following text and illustrations offer suggested

loader and tractor operating techniques.

Figure 3-1

13

Level

Indicator Rod