PCB Layout Guideline

www.ti.com

2.7 Procedure

2.7.1 Power Supply

Make sure EQUIPMENT SETUP steps are followed.

Disconnect LOAD #1. Turn on PS#1.

Measure → V(J1(VBUS)) = 6.5V ± 200mV

Measure → V(J2(VBAT)) = 0V ± 200mV

Measure → V(J4(VTSB)) = 0V ± 200mV

Observe → D1 (PG) ON, D2 (CHG) OFF

2.7.2 Charger Enable and Battery Detection

Connect JP1; Connect 2-3 of JP7 (Charger ON)

Measure → V(J4(VTSB)) = 2.2V ± 300mV

Connect 2-3 of JP5 (Internal TS);

Adjust R6 until V(JP4-1) = 0.7V ± 200mV

Measure → V(J2(VBAT))=4.2V 200mV

Observe → D1 (PG) ON, D2 (CHG) OFF

2.7.3 Charge Current/Voltage Regulation

Reconnect LOAD#1. Turn on. Use the constant voltage mode.

Connect JP1; Set the output voltage to be 2.2V.

Measure → I(J2(VBAT)) = 0.1A ± 50mA

Observe → D1 (PG) ON, D2 (CHG) ON

Increase the voltage of LOAD#1 to be 3.5 V.

Measure → I(J2(VBAT)) = 0.5A ± 100mA

Observe → D1 (PG) ON, D2 (CHG) ON

2.7.4 VDPM ((Input Voltage Regulation) Setting)

Disconnect J3, measure the resistance between J3-1 to GND (6.65kΩ ±10%)

2.7.5 Test Complete

Turn off the power supply and remove all connections from the unit under test (UUT).

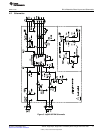

3 PCB Layout Guideline

1. It is critical that the exposed thermal pad on the backside of the bq24210 package be soldered to the

PCB ground. Make sure there are sufficient thermal vias right underneath the IC, connecting to the

ground plane on the other layers.

2. Decoupling capacitors for VBUS, BATC should make the interconnections to the IC as short as

possible.

3. Take the EVM layout for design reference.

6

800mA, Single-Input, Single Cell Li-Ion Battery Solar Charger with Power Path SLUU477–December 2010

Submit Documentation Feedback

© 2010, Texas Instruments Incorporated