ÄÄ

If your engine is equipped with a CLIMATE

GUARD air cleaner, make sure scoop is posi-

tioned correctly:

• WINTER (Below 32

0

F; 0

0

C): Scoop should be pointed directly at muf-

fler.

• SUMMER (Above 32

0

F; 0

0

C): Scoop should be pointed towards blower

housing (approximately 45

0

clockwise from “winter position”).

IMPORTANT: In order for engine to operate smoothly and efficiently, it

is important for scoop to be in proper position for season.

If your engine is not equipped with a CLIMATE GUARD air cleaner,

and you would like to operate your engine in temperatures below 32

0

F

(0

0

C), a CLIMATE GUARD Conversion Kit is available at any Autho-

rized Tecumseh Service Outlet. Order as kit number 730630.

STARTING

NEVER RUN ENGINE INDOORS OR IN ENCLOSED, POORLY

VENTILATED AREAS. ENGINE EXHAUST CONTAINS CARBON

MONOXIDE, AN ODORLESS AND DEADLY GAS.

KEEP HANDS, FEET, HAIR AND LOOSE CLOTHING AWAY FROM

ANY MOVING PARTS ON ENGINE AND EQUIPMENT.

WARNING: TEMPERATURE OF MUFFLER AND NEARBY AREAS

MAY EXCEED 150

0

F (65

0

C). AVOID THESE AREAS.

ÀÀ RECOIL STARTER:

A. Move choke lever (see Figure 3 or 4) to “FULL CHOKE POSITION”.

NOTE: IF RESTARTING A WARM ENGINE AFTER A SHORT

SHUTDOWN, MOVE CHOKE LEVER TO “NO CHOKE

POSITION”.

B. Move equipment control (see manufacturer’s instructions) or engine

control to “START”.

C. Grasp starter handle (see Figure 1) and pull rope out, slowly, until it

pulls harder. Let rope rewind slowly. Then pull rope with a rapid full arm

stroke. Let rope return to starter slowly.

D. When engine starts, move choke lever to “1/2 CHOKE” until engine

runs smoothly and then to “NO CHOKE POSITION”. If engine falters,

move choke lever to “1/2 CHOKE” until engine runs smoothly and then

to “NO CHOKE POSITION”.

NOTE: If engine fails to start after three (3) pulls, move choke lever

to “NO CHOKE POSITION” and pull starter rope again.

NOTE:

If engine fires, but does not continue to run, move choke

lever to “FULL CHOKE” and repeat instructions B, C and D

until engine starts.

BEFORE STARTING

ÀÀ READ ALL INSTRUCTIONS PROVIDED WITH THE EQUIPMENT

ON WHICH THIS ENGINE IS USED.

ÁÁ FILL OIL SUMP OR CHECK OIL LEVEL:

IMPORTANT: To avoid engine damage never run engine unless:

- Oil level is between “FULL” and “ADD” marks on dipstick.

- Oil fill plug is tightened securely into oil fill tube or hole.

CHECK OIL LEVEL OFTEN DURING ENGINE BREAK-IN.

A. POSITION EQUIPMENT SO ENGINE IS LEVEL.

B. Clean area around oil fill plug (see Figure 1).

C. Remove oil fill plug and dipstick.

D. Wipe dipstick clean, insert it into oil fill hole and tighten securely, remove

dipstick. If oil is not up to “FULL” mark on dipstick, add recommended

oil. POUR SLOWLY. Wipe dipstick clean each time oil level is checked.

IMPORTANT: DO NOT FILL ABOVE “FULL” MARK ON DIPSTICK.

E. Install oil fill plug and dipstick, tighten securely.

See “MAINTENANCE” section for further oil instructions.

ÂÂ FILL FUEL TANK:

A. Clean area around fuel fill cap, remove cap.

B. Add “UNLEADED” regular gasoline, slowly, to fuel tank. Use a funnel

to help avoid spillage.

IMPORTANT: NEVER MIX OIL WITH GASOLINE

C. Install fuel fill cap and wipe up any spilled gasoline.

NEVER FILL FUEL TANK INDOORS. NEVER FILL FUEL TANK

WHEN ENGINE IS RUNNING OR HOT. DO NOT SMOKE WHEN

FILLING FUEL TANK.

NEVER FILL FUEL TANK COMPLETELY. FILL TANK TO 1/2'’

BELOW BOTTOM OF FILLER NECK TO PROVIDE SPACE FOR

FUEL EXPANSION. WIPE ANY FUEL SPILLAGE FROM ENGINE

AND EQUIPMENT BEFORE STARTING ENGINE.

ANY LIQUEFIED PETROLEUM (LPG) OR NATURAL GAS FUEL

SYSTEM MUST BE LEAKPROOF AND MEET ALL APPLICABLE

CODES AND REGULATIONS.

Page 2

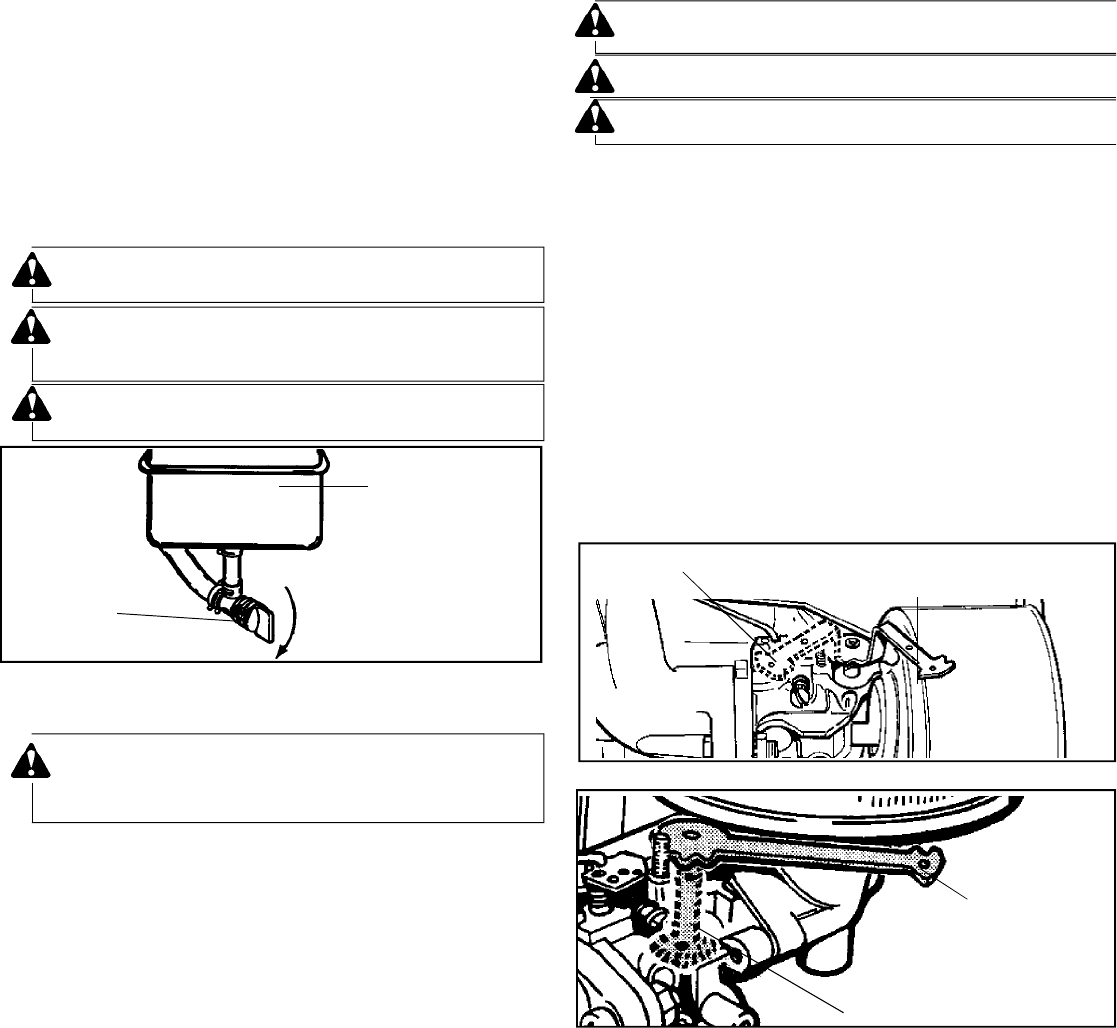

Figure 2

Figure 3

Figure 4

FUEL TANK

FUEL VALVE

"OPEN" POSITION

SHOWN

TURN CLOCKWISE TO

"OFF" POSITION

FULL CHOKE

POSITION

CHOKE LEVER

NO CHOKE POSITION

FULL CHOKE

POSITION

CHOKE

LEVER

NO CHOKE

POSITION

181-630-14

ÃÃ CHECK THE FOLLOWING:

A. BE SURE EQUIPMENT IS IN NEUTRAL GEAR WITH CLUTCHES,

BELTS, CHAINS AND SAFETY SWITCHES DISENGAGED. (FOL-

LOW EQUIPMENT MANUFACTURER’S INSTRUCTIONS.) THIS

SHOULD PLACE ANY SAFETY SWITCHES IN SAFE STARTING

POSITION.

B. Be sure spark plug wire is attached to spark plug (see Figure 1).

C. Be sure stop switch (if so equipped see Figure 1) is not contacting spark

plug.

D. Be sure any ignition switch and/or control lever on engine or equipment

is in “ON”, “RUN” or “START” position.

E. Be sure fuel valve (if so equipped see Figure 2) is open.