24 109821_0508

NOTE:

1. The service intervals after 1000 operation hours should also be made every 100 operation hours in accordance with this

check and maintenance schedule.

2. When the servicing on the asterisked ( * ) items are necessary, consult the equipment supplier.

Explanation of Maintenance Schedule

The following is a brief explanation of the services listed

in the preceding Engine Maintenance schedule.

1. Oil level and condition of oil Check that the oil level is between the max. level mark and the min. level mark. Drain

oil to the max. level mark If oil level is above the max. level mark. Add oil to the max.

level mark if oil is below the min. level mark.

2. Oil leakage check Replace any damaged or malfunctioning parts which could cause leakage.

3. Oil pressure warning lamp Warning lamp is off while engine running. If it stays on, check and repair the lubrication

system.

4. Engine oil replacement Change oil per specified interval.

5. Oil filter element replacement Change element per specified interval.

6. Fuel leakage check Inspect the fuel lines for damage which could cause leakage. Replace any damaged or

malfunctioning parts.

7. Draining water in fuel filter Drain the sedimented water in fuel filter every 100 hours.

8. Fuel filter element replacement Change element every 200 hours.

9. Injection nozzle check Check and adjust injection opening pressure and spray condition (This is a recom-

mended maintenance) every 1000 hours.

10. Coolant level and condition Check coolant level and add coolant if necessary.

check

11. Coolant leakage check Repair or replace parts as required.

12. Radiator filler cap The radiator cap must be installed tightly.

fitting condition

13. Fan belt tension check Check and adjust fan belt tension. Look for cracks, fraying and wear.

14. Overheat warning lamp Coolant temperature is normal at about 75° to 90°C (167° to 194°F)

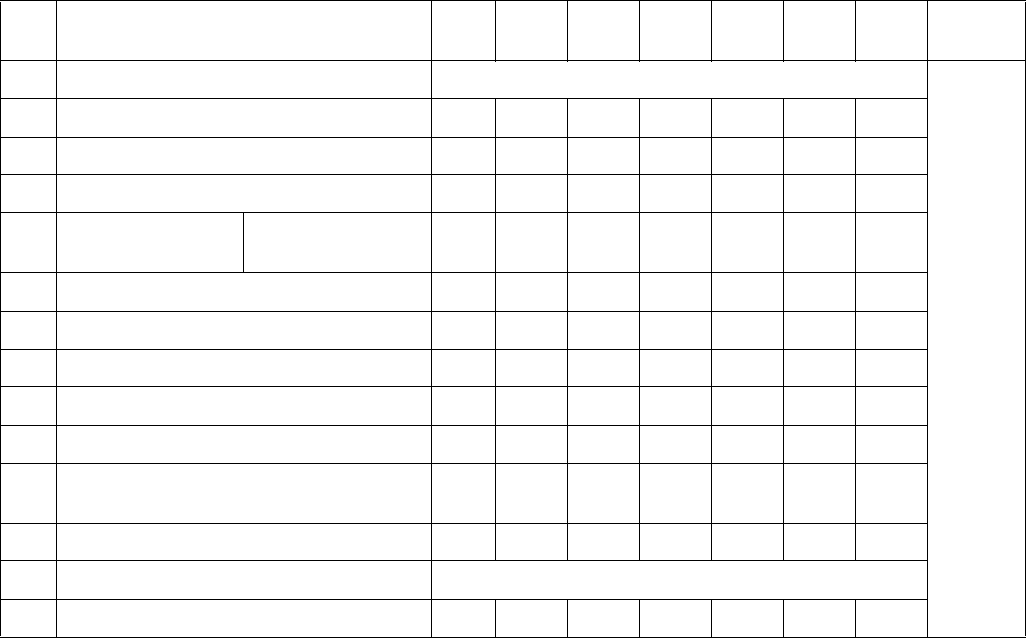

NO Description of check and Maintenance

Daily Initial

50

Every

100

Every

200

Every

400

Every

600

Every

1000

Remarks

17 Cooling system circuit cleaning Yearly

See

' EXPLANATION OF MAINTENANCE SHEDULE'

18 Radiator filler cap function check (*) X

19 Electrolyte level check X

20 Battery cleaning X

21 Battery charge con-

dition

Charge warning

lamp X

22 Electrolyte gravity check X

23 Starter and alternator check and cleaning(*) X

24 Wiring and connection check X

25 Preheating condition check X

26 Air cleaner element replacement X

27 Engine starting conditions and noise condi-

tions X

28 Exhaust smoke condition X

29 Cylinder compression pressure(*) Every 2000 hours

30 Valve clearance check (*) X