20 109821_0508

Specific gravity of the batteries

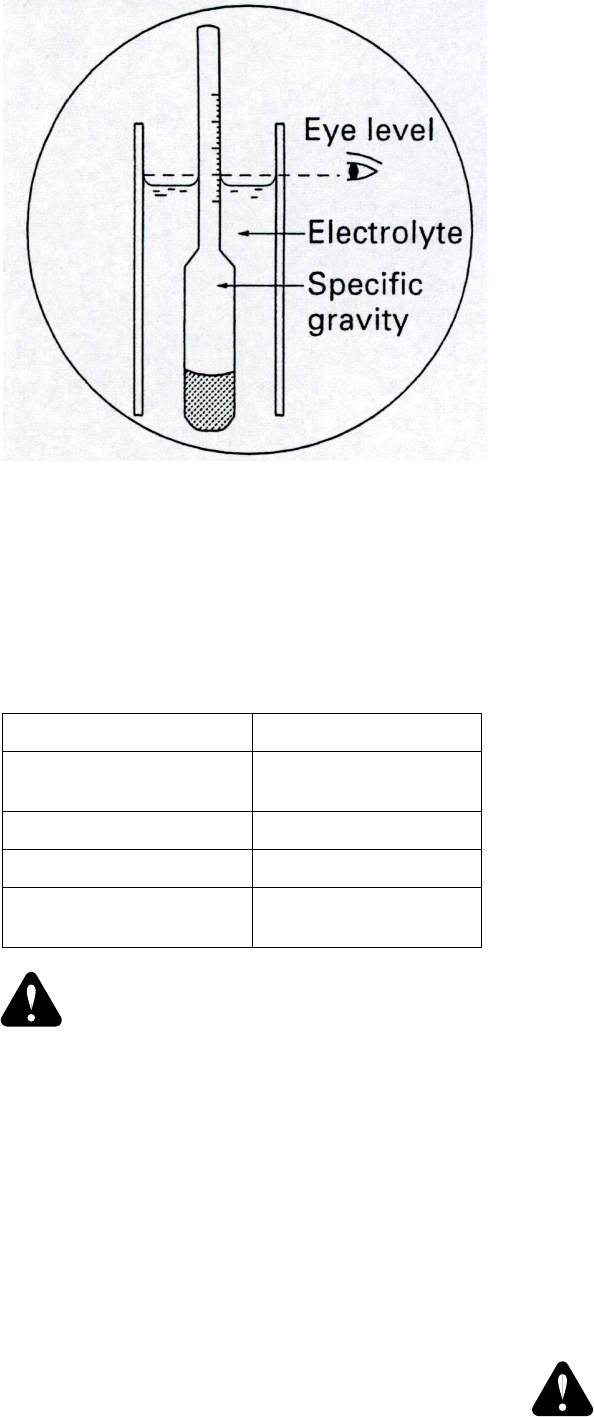

The battery charge condition is judged by the electrolyte

specific gravity measurement.

Periodically measure the electrolyte gravity of the batter-

ies.

For the internal check follow the equipment manufac-

turer's standard.

The relationship between the electrolyte specific gravity

and the battery conditions are as follows:

CAUTION: The battery electrolyte is sulfuric

acid. Prevent contact of electrolyte with skin and

clothes. If this occurs rinse affected area in clean

water.

Specific Gravity Conversion

The specified electrolyte temperature for the gravity mea-

surement is 20°C (68°F).

Measure the electrolyte temperature and use the following

formula for conversion.

S20 = St + 0.0007 (t - 20)

S20 ; gravity at 20°

St ; gravity measured

t ; electrolyte temperature when measured

Battery Terminal Connections

Periodically, check the battery terminals for loose connec-

tion and corrosion.

Follow the equipment manufacturer's recommendation for

intervals.

Loose connections will cause hard engine starting or insuf-

ficient battery charging.

If the terminals are excessively corroded, disconnect the

battery cables and polish them with a wire brush or sandpaper.

Never reverse the "+" and "-" terminals when reconnecting

the cables. Even a short period of reverse connection could

damage the electrical system.

Cleaning of Battery

Clean the battery with clean water or tepid water and wipe

them with a dry cloth to remove the water.

Apply a light coat of petroleum jelly or grease to the bat-

tery post.

(2) Alternator Servicing

1. The polarity of the alternator is negative grounding type.

When an inverted circuit connection takes place, the cir-

cuit will be in short circuit instantaneously resulting in

alternator failure.

2. Do not put water directly on the alternator. Entry of

water into the alternator leads to electrolyte corrosion

causing an alternator failure.

Use caution when cleaning the engine.

3. Disconnect the battery prior to charging with an external

charger.

(3) Wiring Connections

Check all of the electrical wiring for loose connections and

damage.

7.6 Engine Assembly and Others

For continued trouble free engine operation over a long

period of time, the servicing items need a skilled maintenance

technician, therefore, consult your dealer on the following

procedures.

(1) Fuel Injection Nozzle

Use an injection nozzle tester check the static injection

starting pressure and the fuel spray conditions.

Injection nozzle pressure test interval : Every 1000 opera-

tion hours.

When the injection starting pressure is too high or too low

or the fuel spray pattern is improper, an abnormal fuel com-

bustion takes place in the engine leading to lowered output

and blackish exhaust smoke. Further, it can cause a piston

seizure or damage etc. In such cases, the injection nozzle test

or the nozzle replacement is required.

Injection starting pressure …… Refer to the main data and

specifications.

WARNING: When using a nozzle tester, keep

clear of nozzle end. Fuel oil under high pressure

can cause serious injury

Electrolyte Specific Gravity Battery Conditions

Over 1.300 Over 100%

(Over charged)

1.290 - 1.270 100%

1.260 - 1.240 75%

Below 1.230 Below 50%

(Insufficiently charged)