109821_0508 17

When changing the engine oil, add the exact amount

specified in the engine owner’s manual.

NOTE: Use CD grade or better by API classification

engine oil.

MODELS N843 & N843L ONLY — Add oil at the oil

fill shown.

When changing the engine oil, add the exact amount

specified in the engine owner’s manual.

Use CD grade or better by API classification engine oil.

3. Wait about fifteen minutes until the oil gets down to the

oil pan. Then check the oil level with a dipstick. A certain

period of time is required before the engine oil com-

pletely flows down from the oil filler to the crankcase.

(2) Check For Oil Leaks

Idle the engine to raise the oil pressure, then check for oil

leakage.

Oil level recheck

1. Stop the engine and allow the oil to drain to bottom

(approx. 20 minutes).

2. Use the dipstick to recheck the oil level.

3. Add engine oil, if necessary, to bring level to maximum

level.

CAUTION: When the engine is started, the oil

level will slightly drop from the initial level as the

oil fills into the entire oil circuit.

(3) Engine Oil Additives

Engine oils contain a variety of additives. Your engine

should not need any extra additives if you use the recom-

mended oil quality and change intervals.

(4) Used Oil Disposal

Do not dispose of used engine oil (or any other oil) in a

careless manner such as pouring it on the ground, into sewers,

or into streams or bodies of water. Instead, recycle it by tak-

ing it to a used oil collection facility which may be found in

your community. If you have a problem disposing of your

used oil, it is suggested that you contact your dealer or service

station. (This also applies to diesel fuel which is contami-

nated with water. See "Diesel Fuel" in Section 1.)

(5) Used Engine Oil

WARNING: Used engine oil contains harmful

contaminants that have caused skin cancer in labo-

ratory animals. Avoid prolonged skin contact.

Clean skin and nails thoroughly using soap and

water - not mineral oil, fuels, or solvents. Laun-

der or discard clothing, shoes, or rags containing

used engine oil.

Discard used engine oil and other oil properly.

7.2 Cooling System

(1) Fan Belt Tension Adjustment

Adjust fan belt tension when belt becomes loose and when

the belts are replaced. (Refer to Belt Tension section below)

WARNING: To help avoid injury, check and

adjust fan belt tension with engine stopped.

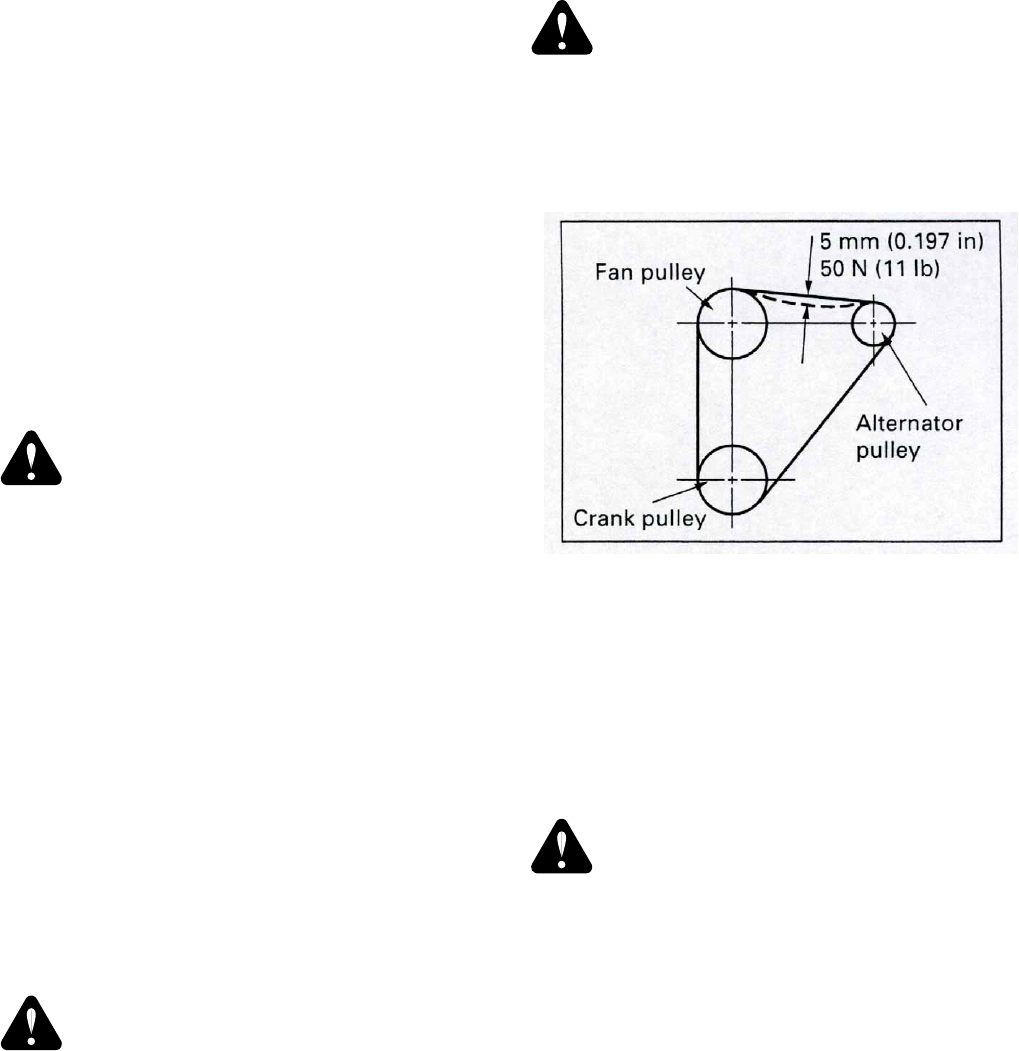

Belt tension

Belt tension is normal when it is depressed 5 mm (0.197

in) with the thumb at the midway between the fan pulley and

alternator pulley. (about 50 N (11 lb) depressing force.)

Fan belt slackness : About 5 mm (0.197 in)

Adjusting procedure

Belt tension adjustment is made by pivoting the alternator

at the alternator mounting bolt.

1. Loosen the alternator adjusting plate bolt and the alterna-

tor mounting bolt.

2. Pivot the alternator at the mounting bolt toward the

engine left or right hand side as required.

3. Tighten the mounting bolt and the adjusting bolt.

CAUTION: Belt tension may vary slightly after

the alternator is tightened. Therefore, recheck the

belt tension after tightening the bolts.

4. After the adjustment, operate the engine about five min-

utes at a low idle speed, stop engine and recheck the belt

tension particularly when installing new belts. Belt ten-

sion may vary due to the initial belt seating.

(2) Fan Belt Change

Use of a low quality fan belt will result in premature belt

wear or belt elongation leading to engine damage such as

overheating. Therefore use of Shibaura genuine fan belt is

highly recommended.