LA000577C © 2006 Navman New Zealand. All rights reserved. Proprietary information and specications subject to change without notice.

6

Pin

Jupiter 30 Jupiter 20

GPIO Name and Description GPIO

Standard &

XTrac name

DR function

24 13 reserved 6 GPIO (SDO) not connected

25 4 reserved 5 GPIO (SDI) ADC DOut

26 –

WAKEUP

push-to-x wakeup (active on +ve edge)

7 GPIO (SCK) ADC Clk

27 15

ANT_OC

antenna open circuit sensor input (active

high)

15 ANT_OC

FWD/REV

fwd/rev input

(low=forward,

high=reverse)

28 1

ANT_CTRL

active antenna control output

1 ANT_CTRL

WHEEL_TICKS

wheel tick input

8 14

NANT_SC

antenna short circuit sensor input (active

low)

3 NANT_SC

GYRO_IN

gyro input

(analogue 0–5 V)

Table 2-2: Summary of pin multi-functionality

GPIO

Note that the Jupiter 20 D (Dead Reckoning) does not support the active antenna supervisory

functionality and associated proprietary NMEA status messaging (see section 3.7).

SPI (Jupiter 20 only)

The Jupiter 20 (GSW2) and Jupiter 20 S (XTrac) do not support the SPI. These pins function

only as user GPIOs.

The SPI on the Jupiter 20 D is used to control an internal ADC, which interfaces to an

external gyro.

Implementation of the SPI for any other alternative function requires an SDK (Software

Development Kit) from SiRF.

2.2 Physical dimensions

The physical dimensions of the Jupiter 30 and Jupiter 20 modules are identical:

length: 25.4 mm ± 0.1 mm

width: 25.4 mm ± 0.1 mm

thickness: 3.0 mm max

weight: 4.0 g max

2.3 Manufacturing process recommendations

2.3.1 Reow recommendations

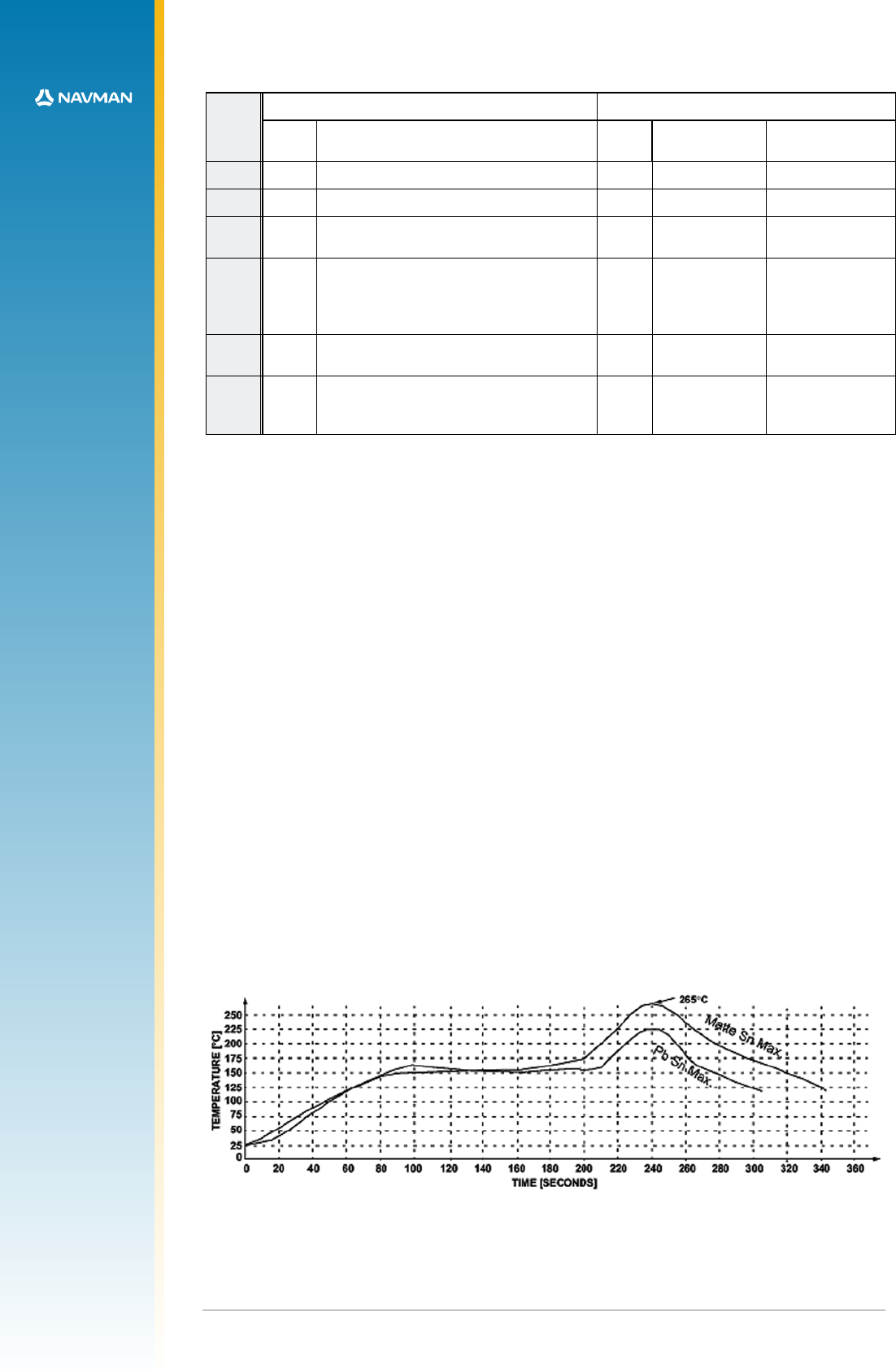

For lead based solder pastes, the maximum reow temperature is 225 °C for 10 seconds. For

lead-free solder pastes, the maximum reow temperature is 265 °C for 10 seconds. Refer to

Figure 2-1.

Figure 2-1: Lead-free and tin/lead reow prole recommendation

2.3.2 Connection pad material

The 30 surface mount connection pads have a base metal of copper with a gold ash nish.

This is suitable for a lead free manufacturing process.