WS-93002N page 3 of 7

Setting the SWICHGAGE

®

contacts

1. Face mounted contacts are set using a 1/16 in. hex wrench.

2. Some models such as 20PE, 20TE, etc. may not have field adjust-

ment. Consult the factory if in doubt.

3. Observe the “normal operating” oil pressure and coolant tempera-

ture readings. Set the oil pressure Swichgage contact slightly below

the minimum reading observed or slightly above the minimum

pressure recommended by the engine manufacturer.

4. Set the temperature Swichgage contact slightly above

the “normal

operating” temperature reading observed or slightly below the maxi-

mum temperature recommended by the engine manufacturer.

NOTE: More detailed instructions are contained in Installation Sheet

P-95033N for pressure Swichgage instruments and T-8446N for

Temperature Swichgage instruments.

Testing the SwichgageInstruments

For face mounted contacts (20P, 20T, 20PW7, etc.):

1. With the engine running; use a

1

/16 in. hex wrench to rotate the con-

tact until it touches the gauge pointer. Do NOT force the contact

against the pointer. Engine should shut down and/or alarm should

operate. Reset the contact.

2. An alternative method of testing the

shutdown circuit is to place a coin

or other metal object between the

contact adjustment and the bezel.

NOTE: This method does NOT test

the actual contact pair. It does test the

circuit beyond the contact.

3. VER

Y IMPORT

ANT

Each time you

start the engine, observe that the Swichgage instruments are indicat-

ing pressure or temperature, etc. Visual inspection and regular test-

ing should be normal procedure to ensure proper operation and to

achieve maximum results from your Swichgage system.

WARNING: If the pressure Swichgage instrument has a

lockout push button on the face, a contact setting higher than the

factory setting will make the lockout device inoperative.

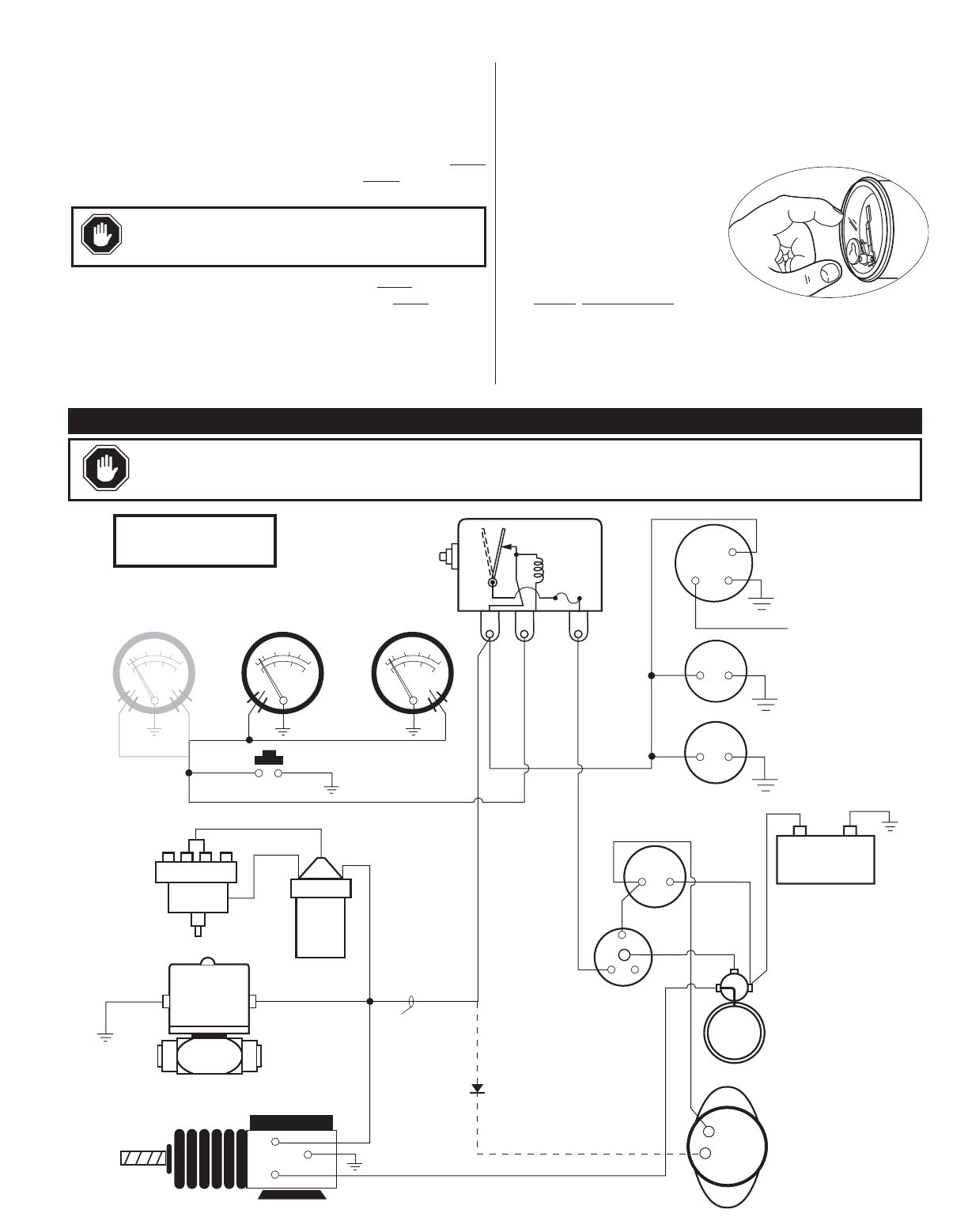

CAUTION: This wiring is typical for Murphy W-Series small engine panels. Items shown may or may not be included in your panel;

however, the circuit is typical of how the component will be wired if it is included. Refer to installation instructions for the specific

component if included. For off-panel items such as shutdown devices, see specific instructions supplied with the device.

TYPICAL WIRING DIAGRAM WITH 117PH MAGNETIC SWITCH

C

S

B

B

+

GRDSIG

_

+

Ignition coil

Distributor

Fuel Valve

Rack Pull Solenoid

(RP2300 Series shown)

Tachometer

Hourmeter

Voltmeter

117PH

20T

Temperature

20P

Pressure

Ammeter

Battery

_

+

_

+

_

+

ST

ACC

IGN

BAT

Start

Switch

Alternator

To Magnetic Sensor,

Alternator “Tach”

Terminal, or

Signal Generator

B

+

Energized

to Run

Model 117PH

Use for 12 or 24 VDC

PB128S Stop Switch

Other

Swichgage instruments

Starter

S

B

Exciter