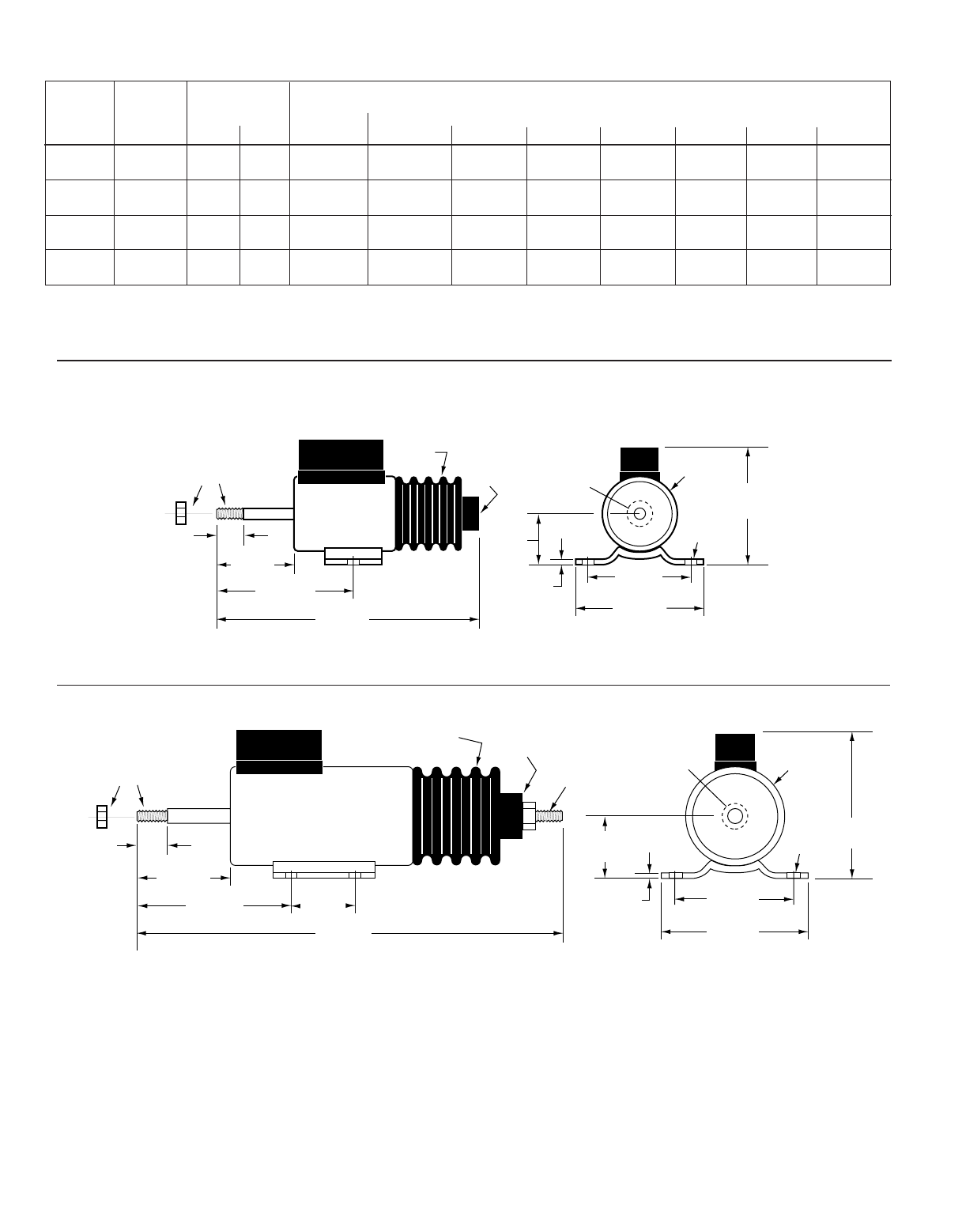

1/2 in.

(13 mm)

1-19/32 in.

(40 mm)

2-13/16 in.

(72 mm)

5 in.

(127 mm)

Boot

Internal

†

1/4-28

1 in.

(25 mm)

3/32 in.

(2 mm)

2 in.

(51 mm)

2-1/2 in.

(64 mm)

2-7/16 in.

(62 mm)

9/32 in.

(7 mm)

1-5/8 in.

Diameter

NOTE: Remove

or pierce decal

to install shaft.

1/4-28 Shaft w/nut

shown installed

(is supplied loose)

3/32 in.

(2 mm)

2 in.

(51 mm)

Diameter

2-1/16 in.

(52 mm)

3-9/32 in.

(83 mm)

1-1/2 in.

(38 mm)

7-7/32 in.

(184 mm)

Boot

Internal

†

1/4-28

1/4-28 Shaft w/nut

shown installed

(is supplied loose)

Shown with

stud and nut

installed.

1-1/8 in.

(28 mm)

3-1/8 in.

(79 mm)

2-1/2 in.

(64 mm)

9/32 in.

(7 mm)

2-7/8 in.

(73 mm)

21/32 in.

(17 mm)

Remove or

pierce decal

to install shaft.

RP2307B and RP2308B

RP2309B and RP2310B

Solenoid Dimensions

Solenoid Shown with Plunger Seated (Coil Energized)

Solenoid Shown with Plunger Seated (Coil Energized)

†

A stud with nut is supplied, loose.

1-1/2 in. (38 mm)—1/4-28

part number: 40-01-0055

Solenoid

Model

Number

Maximum

Stroke

In. (mm)

Power in Watts

Seated Inrush

Force* in Pounds [Kilograms] at 100% Voltage**

Stroke in Inches (Millimeters)

Hold 1/8(3) 1/4(6) 1/2(13) 3/4(19) 1(25) 1-1/4 (32) 1-1/2(38)

Continuous

RP2307B 1 (25) 18 624

25 [11.34] 22 [9.98] 21 [9.53] 17 [7.71] 14 [6.35] 10 [4.54] — —

<13> [5.90] <12> [5.44] <11> [4.99] <10> [4.54] <8> [3.63] <6> [2.72] — —

RP2308B 1 (25) 12 696

27 [12.25] 25 [11.34] 23 [10.43] 19 [8.62] 15 [6.80] 11 [4.99] — —

<15> [6.80] <14> [6.35] <13> [5.90] <12> [5.44] <9> [4.08] <7> [3.18] — —

RP2309B 1-1/2 (38) 18 1029

32 [14.52] 30 [13.61] 27 [12.25] 22 [9.98] 18 [8.16] 13 [5.90] 8 [3.63] 6 [2.72]

<19> [8.62] <18> [8.16] <16> [7.26] <14> [6.35] <11> [4.99] <9> [4.08] <6> [2.72] <4> [1.81]

RP2310B 1-1/2 (38) 12 960

35 [15.88] 34 [15.42] 31 [14.06] 26 [11.79] 22 [9.98] 17 [7.71] 12 [5.44] 7 [3.18]

<20> [9.07] <19> [8.62] <17> [7.71] <15> [6.80] <12> [5.44] <9> [4.08] <7> [3.18] <4> [1.81]

*Forces shown are without return spring. Forces shown < > are with return spring. Forces shown in [ ] are in kilograms.

**To determine the operating current, divide the power (watts) indicated in the above table by the applied voltage.

Solenoids will operate at any stroke less than maximum.

†

A stud with nut is supplied, loose.

1-1/2 in. (38 mm)—1/4-28

part number: 40-01-0055

Watts Power/Cold Force in Pounds at 100% Voltage/Inches Stroke

RPS-00092B page 2 of 4

Note 1. Typical operating temperature for single 15 second operation of the energize coil is less than:

140°F(60°C) ± 10°F (6°C) for 1 in. (25 mm) Stroke Solenoids (70°F/21°C Rise above ambient)

120°F(49°C) ± 10°F (6°C) 1-1/2 in. (38 mm) Stroke Solenoids (50°F/10°C Rise above ambient)

See CAUTION statement on next page and note maximum housing temperature is 185°F (85°C).

Note 2. The energize-coil should not be activated for more than 15 seconds.

Longer energize-coil activation times will damage the solenoid.

Note 3. Allow minimum 15 minutes for cooling between activations of energize-coil to avoid damaging the

solenoid. (Depends on length of time energize coil is energized.)

Note 4. The energize-coil must fully seat the plunger to allow the hold-coil to function properly.